Burnham Series 5B User Manual

Page 19

19

There are many possible causes of oxygen

contamination such as:

1. Addition of excessive make-up water as a result of

system leaks.

2. Absorption through open tanks and fittings.

3. Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

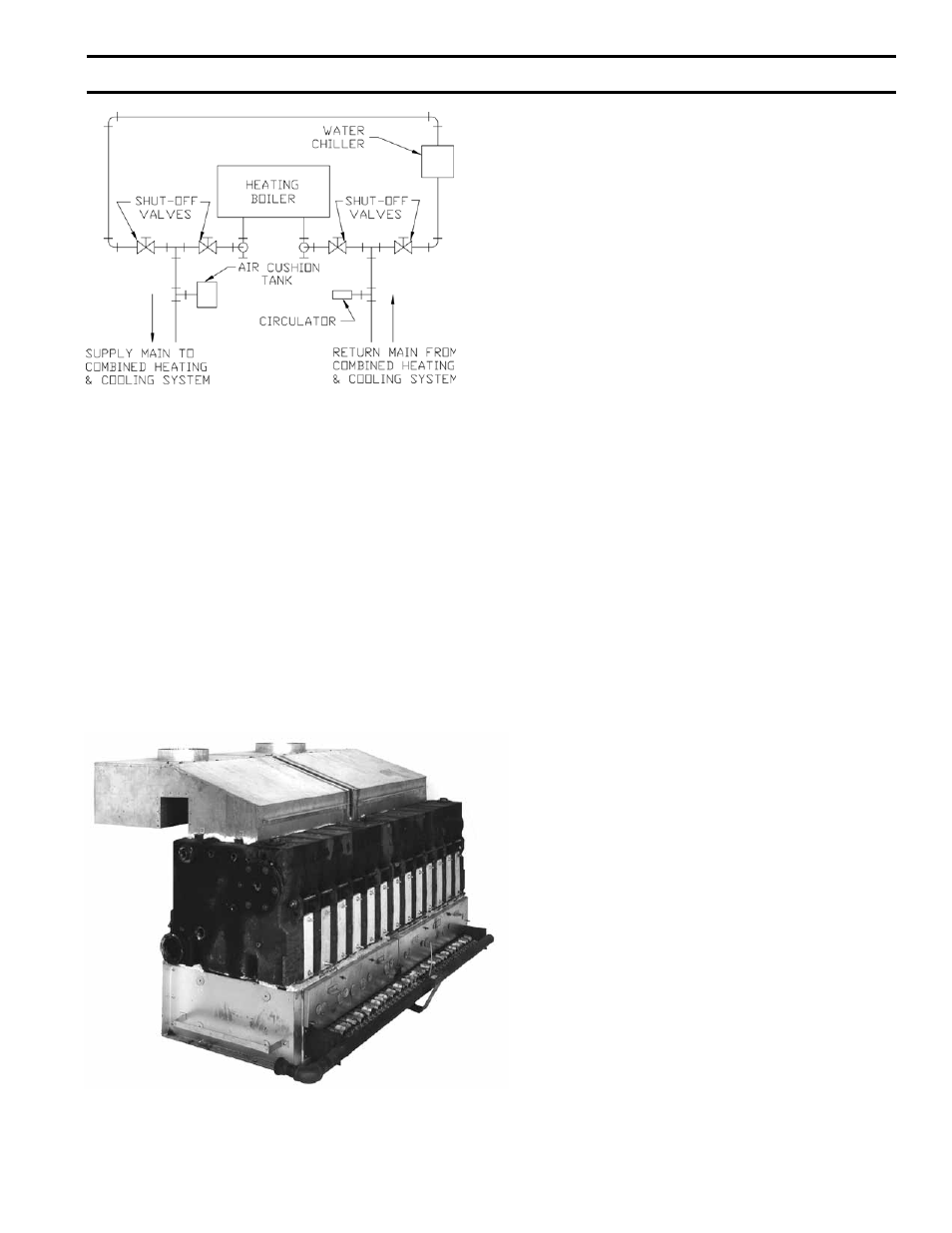

FIG. 17

RECOMMENDED BOILER PIPING FOR

COMBINATION HEATING & COOLING SYSTEMS

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing fittings which allow

oxygen absorption.

4. Use of non-permeable materials in the distribution

system.

5. Isolating the boiler from the system water by

installing a heat exchanger.

Open Jacket Parts Carton

15.

INSTALLATION OF JACKET PARTS COMMON TO

ALL BOILER SIZES

1. Attach Lower Jacket End Panel Support Bracket to

Base End Panel (Both ends) using ¼”-20 x ½” self-

tapping screws, see Fig. 2 and 18.

2. Attach Lower Left and Lower Right Jacket End

Panels to their respective brackets using #10-32 x

½” self-tapping screws, see Fig. 19.

3. See Fig. 7 “Purpose of Tappings and Their

Location” and remove necessary knockouts from

Upper Left and from Upper Right Jacket End

Panels.

4. Place Upper Right End Panel on top of Lower

Right End Panel with lip on bottom of Upper Panel

positioned behind Lower Panel. Secure to section

using #10-32 x ½” self-tapping screws. Attach

Upper Left End Panel in a similar manner, see Fig.

19.

NOTE: FOR INSTALLATION OF THE

FRAMEWORK FOR THE LOWER UNCOMMON

JACKET PARTS REFER TO THE FOLLOWING:

a. 5006B thru 5010B section boilers – Paragraph

16, Fig. 21

b. 5011B thru 5026B section boilers – Paragraph

30, Fig. 25

COMPLETION OF JACKET INSTALLATION –

5006B THRU 5010B SECTION BOILERS

NOTE: Do not tighten any screws until Jacket

installation is complete.

INSTALLATION OF LOWER FRAMEWORK

16.

With “U” channel facing down, slip upper front channel

behind joints formed by End Panels and secure to End

Panels using #8 SMS. Position Lower Front Channel

so that “U” of channel faces boiler. Slip Lower Front

Channel behind Lower End Panels and secure with

#8 SMS. Repeat similar procedure for installation of

Upper Rear and Lower Rear Channels.

17.

INSTALLATION OF VESTIBULE PANEL refer to

Fig. 20.

FIG. 18

INSTALLATION OF JACKET SUPPORT

BRACKETS TO BASE END PANELS

SecTiON iii – iNSTALLATiON iNSTRUcTiONS (continued)