Recommended water quality requirements – Burnham Series 5B User Manual

Page 42

42

b. Draw about 5 gallons of hot water from

boiler into a container and dissolve into it the

appropriate amount of a recommended boilout

compound. Remove safety valve from boiler

and pour this solution into boiler, then reinstall

safety valve.

c. Turn on burner and keep operating while feeding

water to boiler slowly. This will raise water

level in boiler slowly into supply main and back

through return main, flowing from drain hose

at about 180ºF. Continue until water runs clear

from drain hose for at least 30 minutes.

d. Stop feeding water to boiler but continue

operating burner until excess water in boiler

flows out through supply main and water lowers

(by steaming) until it reaches normal level in

boiler.

Turn off burner. Drain boiler. Open all radiator

valves. Reinstall all supply main air valves.

Open gate valve in Hartford Loop.

e. When boiler has cooled down sufficiently

(crown-sheet of sections are not too hot to

touch), close the drain valves at boiler and in

return main and feed water slowly up to normal

level in boiler. Turn on burner and allow boiler

to steam for 10 minutes, then turn off burner.

Draw off one quart of water from bottom gauge

glass fitting and discard. Draw off another quart

sample and if this sample is not clear, repeat the

cycle of draining the boiler and return main and

refilling the boiler until sample is clear.

f. If the boiler water becomes dirty again at a later

date due to additional sediment loosened up in

the piping, close gate valve in Hartford Loop,

open drain valve in return main, turn on burner

and allow condensate to flow to drain until it has

run clear for at least 30 minutes while feeding

water to boiler so as to maintain normal water

level. Turn off burner, drain boiler, open gate

valve in Hartford Loop, then repeat step 1 above.

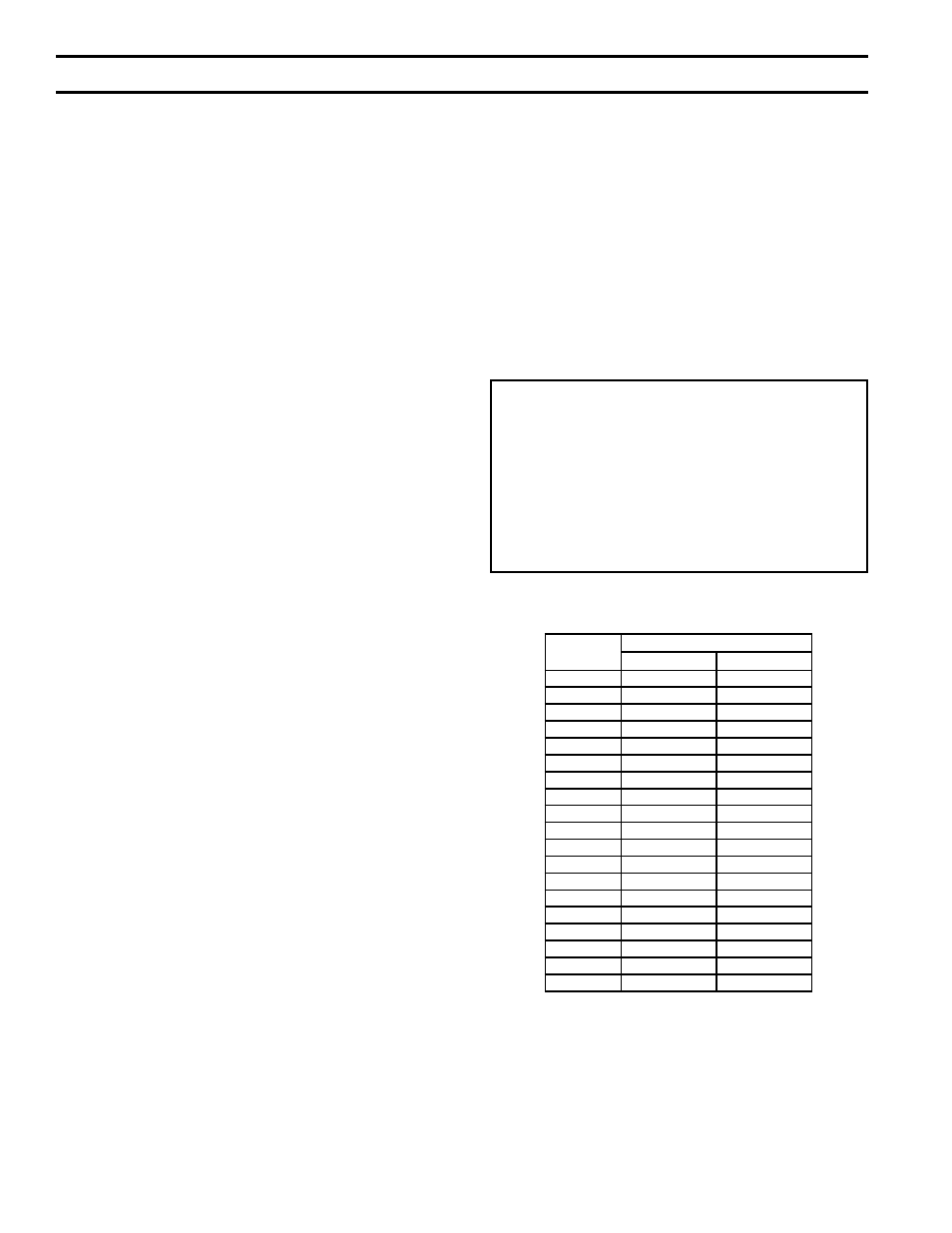

3. Make pH or Alkalinity Test

After boiler and system have been cleaned and

refilled as previously described, test the pH of

the water in the system. This can easily be done

by drawing a small sample of boiler water and

testing with Hydrion paper which is used in the

Boiler Size

Water Content (Gallons)

Water Boiler

Steam Boiler

5006B

37.6

25.6

5007B

43.4

29.3

5008B

49.1

33.0

5009B

54.9

36.8

5010B

60.6

40.5

5011B

66.4

44.2

5012B

72.1

47.9

5013B

77.9

51.6

5014B

83.7

55.4

5015B

89.4

59.1

5016B

95.2

62.8

5017B

100.9

66.5

5018B

106.7

70.2

5019B

112.5

73.9

5020B

118.2

77.7

5021B

124.0

81.4

5022B

129.7

85.1

5024B

141.2

92.5

5026B

152.8

100.0

Table IV: WaTer ConTenT

SeCTIon IV - oPeraTIon (continued)

recommended Water Quality requirements

pH: 8.3 - 10.5

TDS: < 3500 ppm

Total alkalinity ppm as CaCo

3

: < 1200

Total copper ppm: < .05

oily matter ppm: < -1

Total harness ppm: < -3

Chlorides: < 50 ppm

same manner as litmus paper, except that it gives

specific readings. A color chart on the side of

the small hydrion dispenser gives the reading in

pH. Hydrion paper is inexpensive and obtainable

from any chemical supply house or through your

local druggist. The pH should be in accordance

to “Minimum Water Quality Requirements” chart

below. Add some washout chemicals (caustic soda),

if necessary, to bring the pH within the specified

range. With this lower level of protection, care must

be exercised to eliminate all of the free oxygen in

the system.

4.

Boiler is now ready to be put into service.