Caution – Burnham Series 5B User Manual

Page 62

62

cAUTiON

The following procedures should only be

performed by a qualified service technician.

15.

MINIMUM INPUT ADJUSTMENTS

This section covers Minimum Input Adjustments on

Honeywell V8944B Diaphragm Type “Lo-Hi-Lo” Gas

Valves, Honeywell V5055B Fluid Power Gas Valves

equipped with either a V4062A “Lo-Hi-Lo” Actuator or

a V9055A “Modulating” Actuator.

a. Minimum Input Adjustments – “Lo-Hi-Lo”

Combination Valve, V8944B (Natural Gas Only)

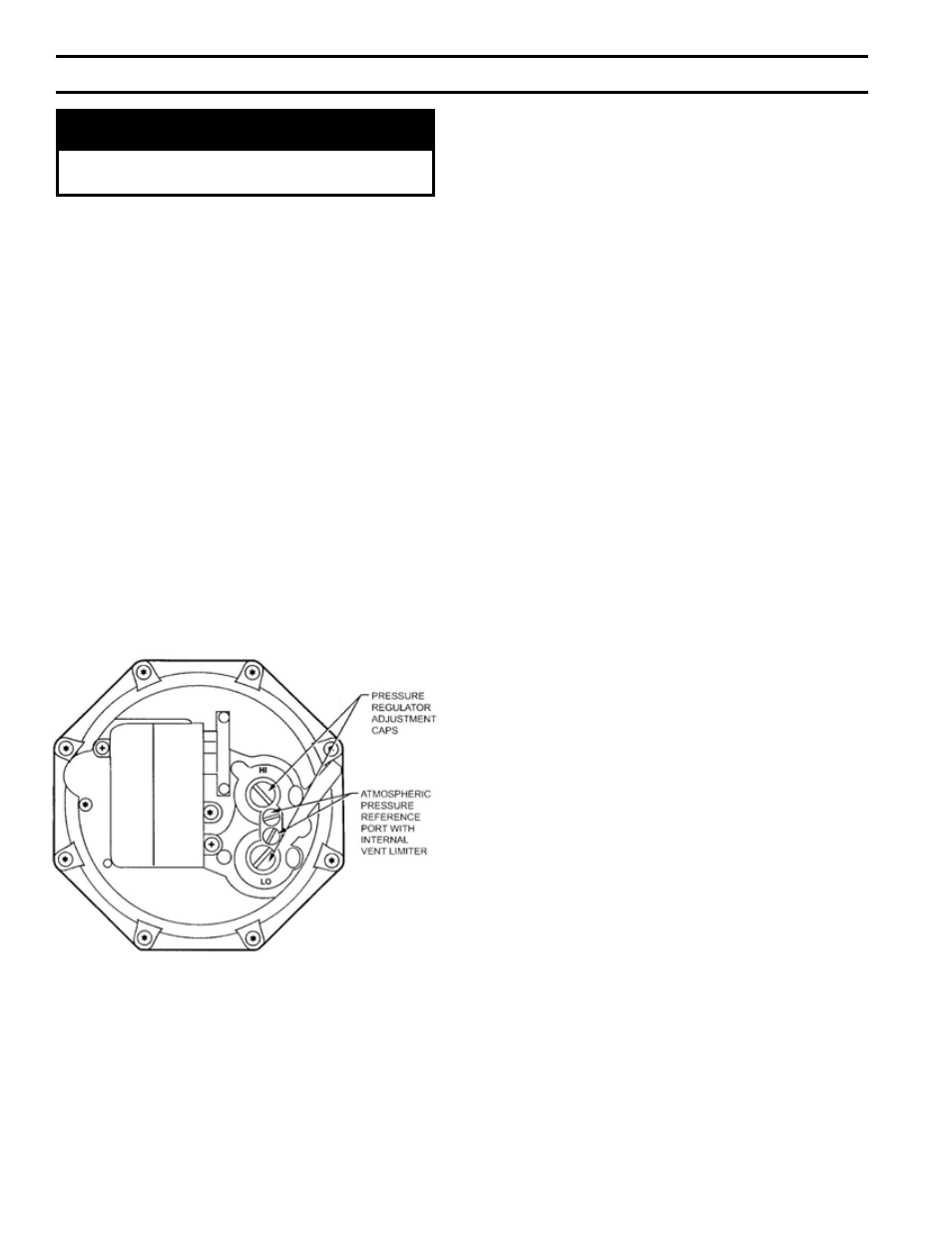

On boilers equipped with the V8944B combination

diaphragm valve/regulator, Low Fire Adjustment

should not be less than Minimum Input shown on

Rating Plate (1/3 of full rated input). Fig. 52 shows

the outlet pressure adjustment screws for low and

high fire. The V8944B low and high fire pressure

settings are factory set at 0.8” and 3.5” W.C.

respectively. If further adjustments are necessary,

remove pressure regulator adjustment caps and

insert a screwdriver to raise or lower the regulator

pressure.

c. MINIMUM INPUT ADJUSTMENTS –

MOTORIZED “MODULATING” ACTUATOR,

V9055A

On boilers equipped with Fluid Power Valves that

have “Modulating” Actuators, Low Fire Adjustment

should not be less than Minimum Input shown on

Rating Plate (1/3 of full rated input).

Fig. 54 shows the Low Fire Adjusting Screw for

increasing or decreasing low fire input on the

Honeywell V9055A “Modulating” Actuator. To

adjust the low fire setting after the burners are “on”,

the following procedure should be used.

(1) With power to actuator “off”, remove the wiring

compartment cover.

(2) Check to make sure the low fire adjustment is

set at MAX (full clockwise) to insure a safe

light-off. (Low fire adjustment is preset at the

factory in the MAX position.)

Fig. 53 shows the Limit Switch Cam and Scales to

indicate direction to rotate cam for increasing or

decreasing low fire input on the Honeywell V4062A

“Lo-Hi-Lo” Actuator. To adjust the low fire setting

after the burners are “on”, the following procedure

should be used.

(1) With power to actuator “off”, remove the

wiring compartment cover.

(2) Check to be sure the low fire adjustment is set

at MAX to insure a safe light-off. (Low fire

adjustment is preset at factory in the MAX

position.)

(3) Disconnect the controller lead from terminal #4

on the actuator to keep the valve in the low fire

position.

(4) Start the system and establish the main burner

flame.

(5) Loosen the setscrew in the cam (Fig. 53) with

the special wrench taped to inside of actuator

cover. Keep the wrench seated in the setscrew.

Rotate the cam slightly downward (by moving

the wrench toward the base of actuator) to open

bleed valve. Actuator will start to close.

(6) When valve reaches desired low fire position,

quickly tighten setscrew and remove wrench. If

the desire low fire setting is “missed”, merely

loosen the setscrew and rotate cam in the

opposite direction to the desired set point.

(7) Shut down burner, and then restart. Repeat

several times to be sure the low fire setting

is that desired and suitable for correct burner

lightoff. Readjust if necessary.

(8) Disconnect power and reconnect controller lead

removed in step (3) above.

(9) Replace the wiring compartment cover.

b. MINIMUM INPUT ADJUSTMENTS –

“Lo-Hi-Lo” MOTORIZED ACTUATOR, V4062A

On boilers equipped with Fluid Power Valves that

have “Lo-Hi-Lo” Actuator, Low Fire Adjustment

should not be less than Minimum Input shown on

Rating Plate (1/3 of full rated input).

SecTiON iV - OPeRATiON (continued)

FIG. 52

V8944B COMBINATION VALVE