11 eliminating faults – Festo Фиксаторы KPE User Manual

Page 33

DNCKE-.../KEC-...

Festo DNCKE-.../KEC-... 0204NH English

33

11

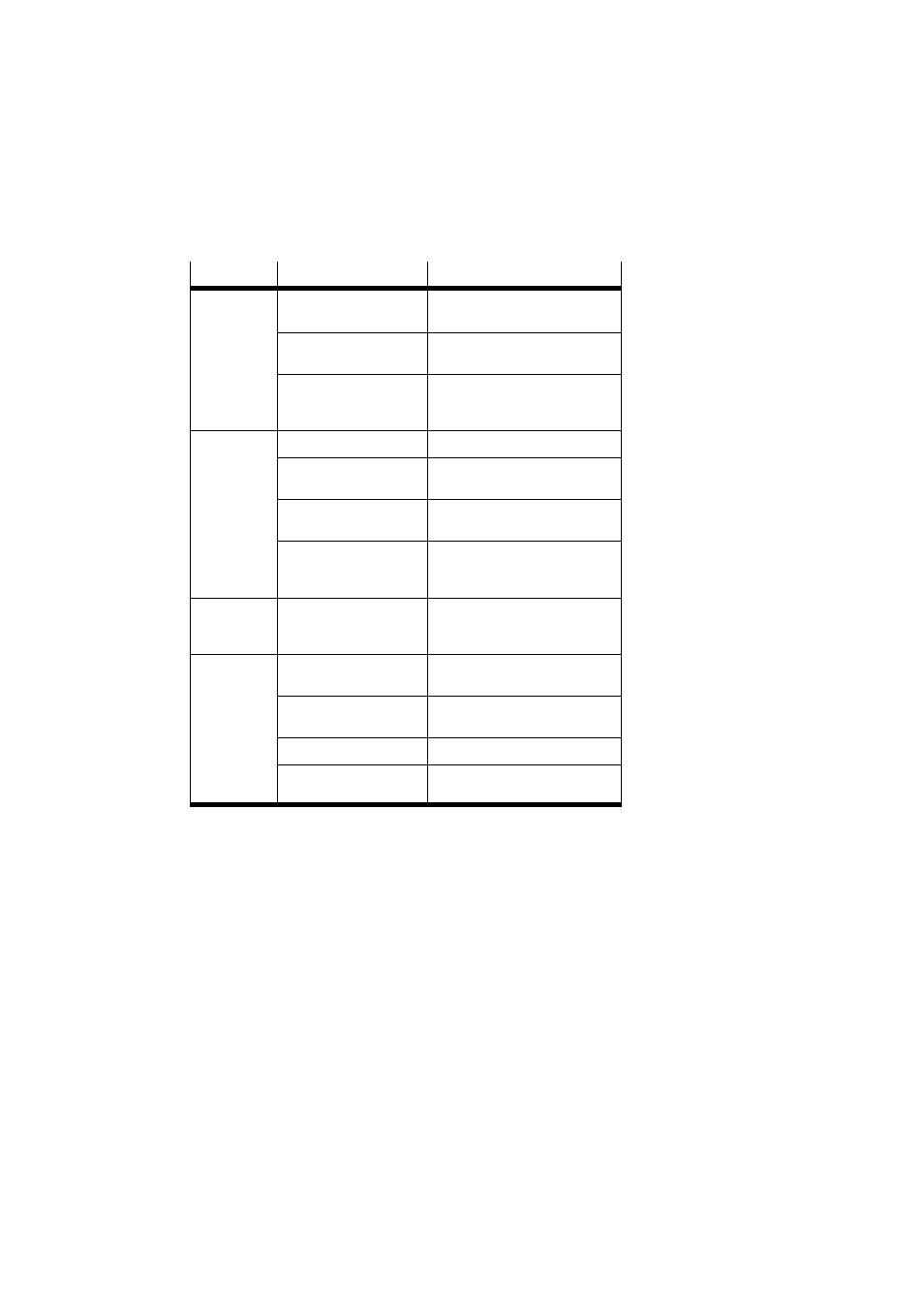

Eliminating faults

Fault

Possible cause

Remedy

Clamping does Clamping unit is not

Return to Festo with description of

Clamping does

not open

Clamping unit is not

sealed tight

Return to Festo with description of

fault

Operating pressure too

low

Increase operating pressure up to

maximum permitted value.

KEC-... not correctly

adjusted

Adjust clamping rod again

(see chapter ”Commissioning –

preparation”)

Clamping rod

b

ks

Mass too high

Reduce the accelerated mass

breaks

through

Speed too high

Select lower speed / brake

additionally with power valves

Clamping rod dirty

Clean the clamping rod with a soft

cloth and protect from dirt

KEC-... not correctly

adjusted

Adjust clamping rod again

(see chapter ”Commissioning –

preparation”)

Hard knocking

in cylinder end

position

Speed too high

Insufficient cushioning

Reduce impact speed / increase

cushioning or use additional

external cushioning elements

Faults in

position

i t

ti

Position of the proximity

switch incorrect

Correct the position of the

proximity switch

interrogation

on the

DNCKE-...

Incorrect type of proximity

switched used

Use only proximity switches of

type SME/SMT-8-...-B

Proximity switch defective

Replace proximity switch

Ferritic parts in vicinity of

proximity switch

Use parts made of non-magnetic

materials

Fig. 29