Red Lion LEGEND User Manual

Page 9

During Reset to Preset modes of operation, any remainder greater than 0.5 will

cause the display to be rounded up. Due to this rounding action, the output

activation may appear to be delayed. In actuality the display may have rounded up

or down, but the internal count had not yet reached the preset value or zero.

The Process and Batch Counters have three Reset Action modes associated

with their displays; Reset to Zero (up-count modes), Reset to Preset (down-count

modes), or Reset to the Counter Load value. Both counters can be independently

programmed to operate in one of these reset modes. A Reset can be a manual

reset, using a programmable User Input, or it can be one of the seven

programmable Automatic Reset modes. Both the reset action and automatic reset

modes are programmed in the Program Counter Module.

The Process Counter displays the scaled

number of pulses in the current Batch cycle.

The Batch counter displays the number of

processes that have been completed. When

the process count equals either preset 1 or 2

depending on the selection of the automatic

reset mode, the Batch count increments by

one. If the automatic reset mode is disabled,

the batch counter will increment at the

preset 2 value (if Output 2 is assigned to

Process). The Batch count can also be

programmed to automatically reset.

The Total Count is the scaled total number

of counts that have been received since the

Total was last reset. It can be used to keep a

running total of process units on a desired per

shift, per day, per week, etc. basis. The Total

counter can also be used to convert the

Process Counter value to different units of

measure (i.e feet to meters, etc.). The

direction of count for the Total is dependent

on the process count direction and the Total

reset mode. The Total count can be

programmed to reset to zero, or reset to preset

3 and requires a manual reset by a User Input.

The reset can be independent of the process

and batch count.

The signal at Input A is used for the Rate indicator. The rate indicator uses a

time interval method (1/tau) to calculate the rate value. The unit counts on the

negative edge of the input pulses. After the programmed minimum update time

elapses and the next negative edge occurs, the unit saves the number of edges that

occurred during the elapsed time. The number of edges is multiplied by the Rate

Scale Factor, Rate Scale Multiplier, and the Rate Conversion Factor to calculate

the rate value. Averaging can be accomplished by programming the Rate

Minimum Update Time for the desired response. Extensive scaling capabilities

allow practically any desired reading at very slow count rates.

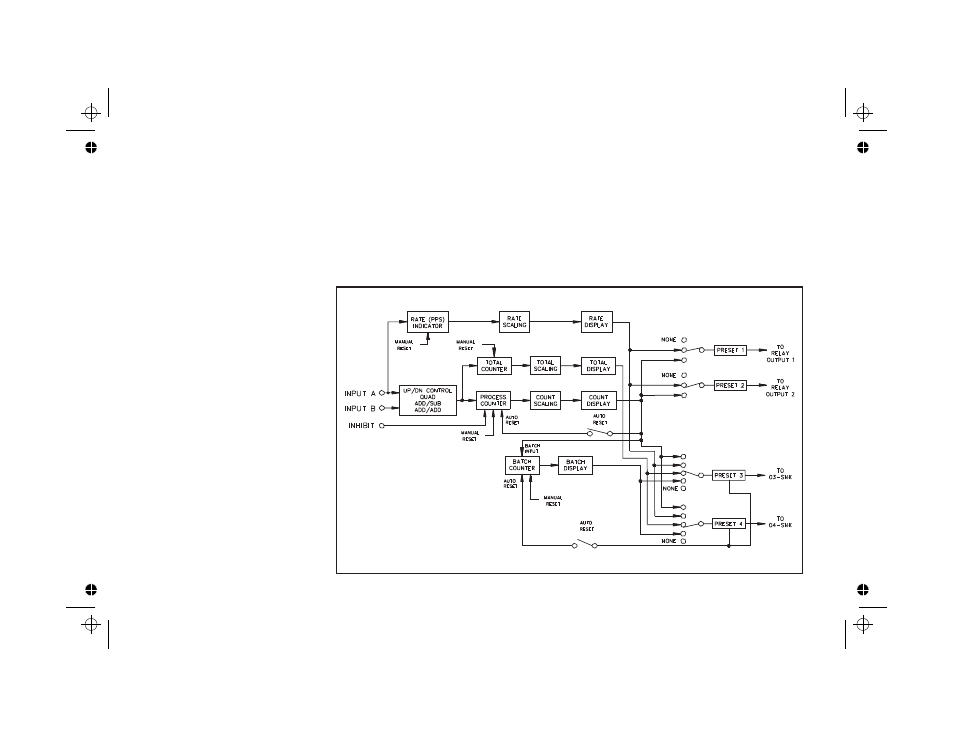

The following is a Block Diagram overview of the basic operation.

-7-