Ag Leader EZ-Guide 500 Variable Rate Getting Started Guide User Manual

Page 40

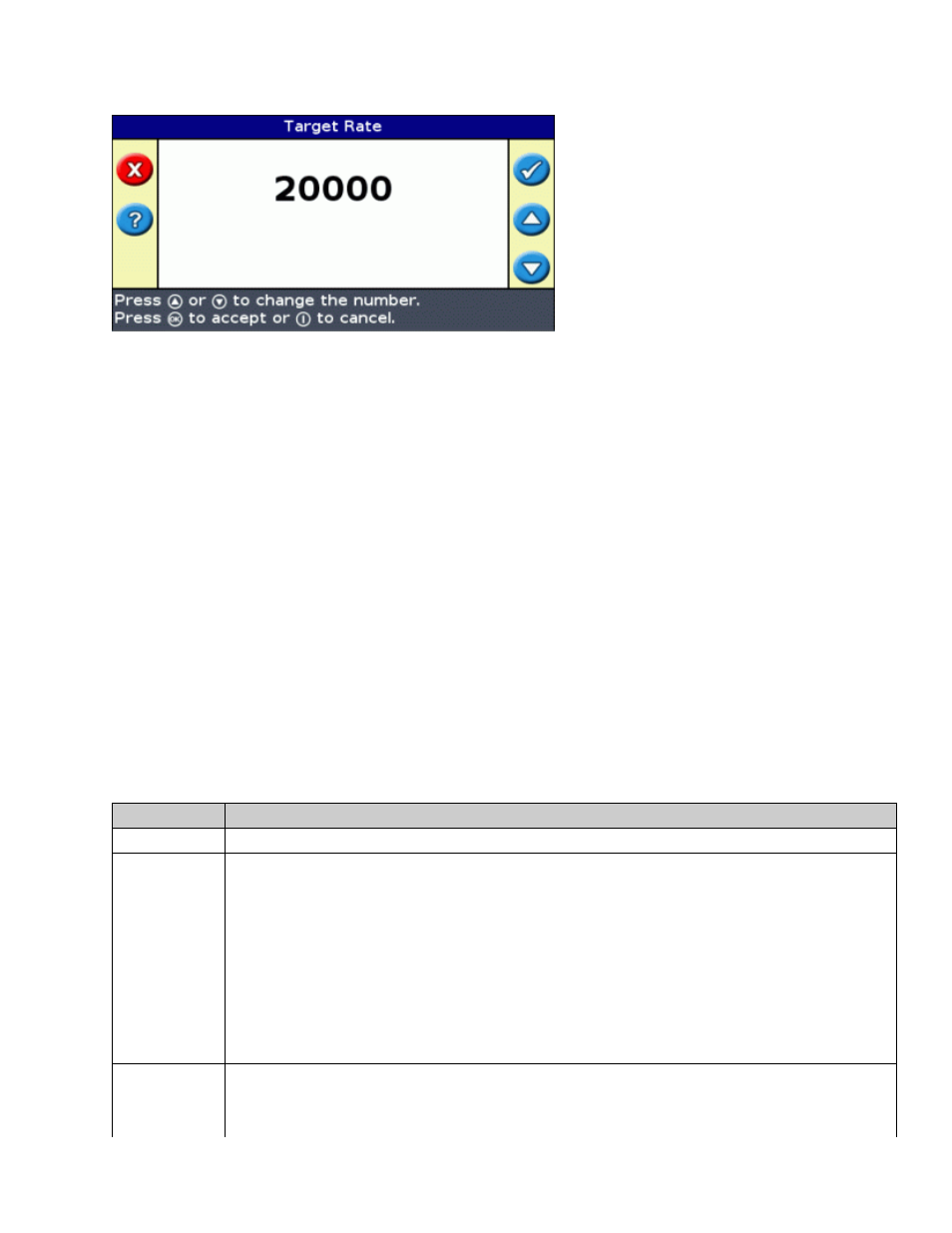

To manually enter a rate to send to the controller, select Configuration / Application Control / Target Rate .

Note: The Target Rate screen will give the same set of steps as available using the control knob on the Raven

controller.

Alternatively, load a prescription so the EZ−Guide 500 lightbar automatically sends target rates to the Rawson

controller. For more information, see Prescriptions.

Note: When using a prescription with the Rawson controller, the target rates in the prescription must match the

step sizes in the Rawson controller. For example, if the default is 25000 and the step size is 4%, then the target

rate values accepted by the Rawson controller are 26000, 27000, 28000…40000. Otherwise, the Rawson

controller may not be able to apply the correct rate.

Note: When the EZ−Guide 500 lightbar is sending target rates to the Rawson controller, the Target Rate screen

on the Rawson controller will always be displayed. To change or view any other screen on the Rawson controller,

you will need to unplug the EZ−Guide 500 cable.

Automatic boom switching

The EZ−Guide 500 lightbar will do automatic boom switching for the Rawson variable rate controller. However,

it only turns the whole boom on or off. Individual boom sections are not automatically controlled.

Use the Swath Control menu to configure the following settings:

ITEM

DESCRIPTION

Boom Control Enable or disable automated boom switching contol.

Allowable

Overlap

Controls the amount of overlap allowed before a boom section is switched off.

For example, if Allowable Overlap is set to:

* 99% − 99% of the boom section is allowed to overlap before it is switched off. This provides

the least amount of skip. Use this setting if you need to ensure complete coverage and using

extra material does not matter.

* 50% − half of the boom section is allowed to overlap before it is switched off.

* 1% − 1% of the section width is allowed to overlap before it is switched off. This allows the

least overlap. Use this setting if you need to conserve the maximum amount of material.

Note: When going from sprayed to unsprayed areas the reverse is true. For example, with 1%

Allowable Overlap, the section width has to be in 99% uncovered area before it switches on.

Boom Valve

Latency

Allows you to account for delays in the spray system. For correct operation, you must set this to

match the delay in your sprayer.

There are two settings, measured in seconds:

38