Troubleshooting – A.O. Smith 3400 User Manual

Page 59

59

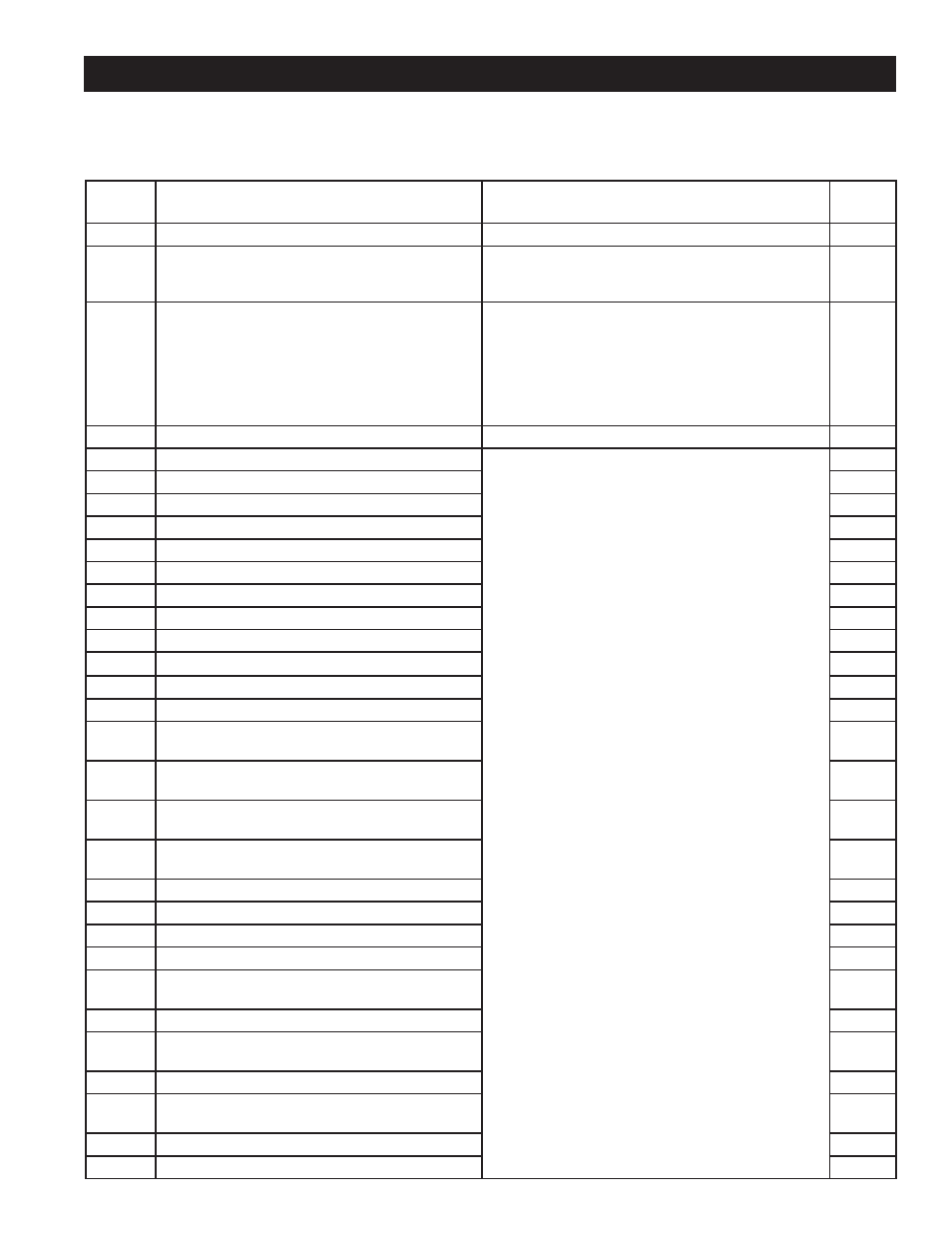

To support the recommended Troubleshooting, the R7910 has an Alert File. Review the Alert history for possible trends that may have

been occurring prior to the actual Lockout.

Note Column: H= Hold message; L=Lockout message; H or L= either Hold or Lockout depending on Parameter Configuration.

CODE

DESCRIPTION

RECOMMENDED TROUBLESHOOTING OF

LOCKOUT CODES

NOTE

Safety Data Faults

1

Unconfigured safety data

1. New Device, complete device configuration and

safety verification.

2. If fault repeats, replace module.

L

2

Waiting for safety data verification

1. Device in Configuration mode and safety

parameters need verification and a device needs

reset to complete verification.

2. Configuration ended without verification, re enter

configuration, verify safety parameters and reset

device to complete verification.

3. If fault repeats, replace module.

L

Internal Operation Errors

3

Internal fault: Hardware fault

Internal Fault.

1. Reset Module.

2. If fault repeats, replace module.

H

4

Internal fault: Safety Relay key feedback error

H

5

Internal fault: Unstable power (DCDC) output

H

6

Internal fault: Invalid processor clock

H

7

Internal fault: Safety relay drive error

H

8

Internal fault: Zero crossing not detected

H

9

Internal fault: Flame bias out of range

H

10

Internal fault: Invalid Burner control state

L

11

Internal fault: Invalid Burner control state flag

L

12

Internal fault: Safety relay drive cap short

H

13

Internal fault: PII shorted to ILK

H or L

14

Internal fault: HFS shorted to LCI

H or L

15

Internal fault: Safety relay test failed due to

feedback ON

L

16

Internal fault: Safety relay test failed due to safety

relay OFF

L

17

Internal fault: Safety relay test failed due to safety

relay not OFF

L

18

Internal fault: Safety relay test failed due to

feedback not ON

L

19

Internal fault: Safety RAM write

L

20

Internal fault: Flame ripple and overflow

H

21

Internal fault: Flame number of sample mismatch

H

22

Internal fault: Flame bias out of range

H

23

Internal fault: Bias changed since heating cycle

starts

H

24

Internal fault: Spark voltage stuck low or high

H

25

Internal fault: Spark voltage changed too much

during flame sensing time

H

26

Internal fault: Static flame ripple

H

27

Internal fault: Flame sensor shorted to ground

detected

H

28

Internal fault: A/D linearity test fails

H

29

Internal fault: Flame bias cannot be set in range

H

TROUBLESHOOTING

TABLE 22. TROUBLESHOOTING CODES