Gas supply connections – A.O. Smith 3400 User Manual

Page 39

39

6. Use pipe sealing compound compatible with propane gases.

Apply sparingly only to male threads of the pipe joints so that

pipe dope does not block gas flow.

Failure to apply pipe sealing compound as detailed in this

manual can result in severe personal injury, death, or substantial

property damage.

7. Make sure the maximum inlet gas pressure do not exceed

the value specified. Minimum value specified is for input

adjustment only.

Make sure to use two wrenches when tightening gas piping at the

boiler, using one wrench to prevent the boiler gas line connection

from turning. Failure to support the boiler gas connection pipe to

prevent it from turning could damage gas line components. Do

not use wrench on valve body as damage would occur.

GAS PRESSURE REQUIREMENTS

The maximum allowable gas supply pressure for this boiler is

14 inches w.c. (3.5 kPa). Install a positive lock-up gas pressure

regulator in the gas supply line if inlet gas pressure can exceed

14 inches w.c. (3.5 kPa) at any time.

If a positive lock-up regulator is required follow these instructions:

1. Positive lock-up gas pressure regulators must be rated at or

above the input Btu/hr rating of the boiler they supply.

2. Positive lock-up gas pressure regulator(s) should be

installed no closer than 3 feet (0.9 m) and no farther than 8

feet (2.4 meters) from the boiler’s inlet gas connection.

3. After installing the positive lock-up gas pressure regulator(s),

an initial nominal supply pressure setting of 7 inches w.c.

(1.7 kPa) while the boiler is operating is recommended and

will generally provide good boiler operation. Some addition

adjustment maybe required later to maintain a steady gas

supply pressure.

4. When installing multiple boilers in the same gas supply

system it is recommended that individual positive lock-up

gas pressure regulators be installed at each unit.

GAS SUPPLY CONNECTIONS

GAS SUPPLY PIPE CONNECTIONS

1. Make sure to install ground joint union for servicing.

In Canada – When using manual main shutoff to support the

weight of the piping with valves, ensure that it is identified by the

installer.

2. Install sediment trap per NFPA 54 for US and CAN B149.1

for Canada.

3. Support the piping with hangers, not by the boiler or its

accessories. The gas control valve and blower will not

support the weight of the piping. Failure to comply could

result in severe personal injury, death, or substantial

property damage.

4. Purge all air from the gas supply piping.

5. Before setting the boiler in operation, check the boiler and its

gas connection for leaks.

• Disconnect the boiler from the gas supply piping system

during any pressure testing, at a test pressure in excess

of 1/2 PSIG (3.5 kPa)

• The boiler must be isolated from the gas supply piping

system by closing a manual shutoff valve during any

pressure testing, at test pressures equal to or less than

1/2 PSIG (3.5 kPa).

Do not check for gas leaks with an open flame, instead use the

bubble test. Failure to use the bubble test or check for gas leaks

can cause severe personal injury, death, or substantial property

damage.

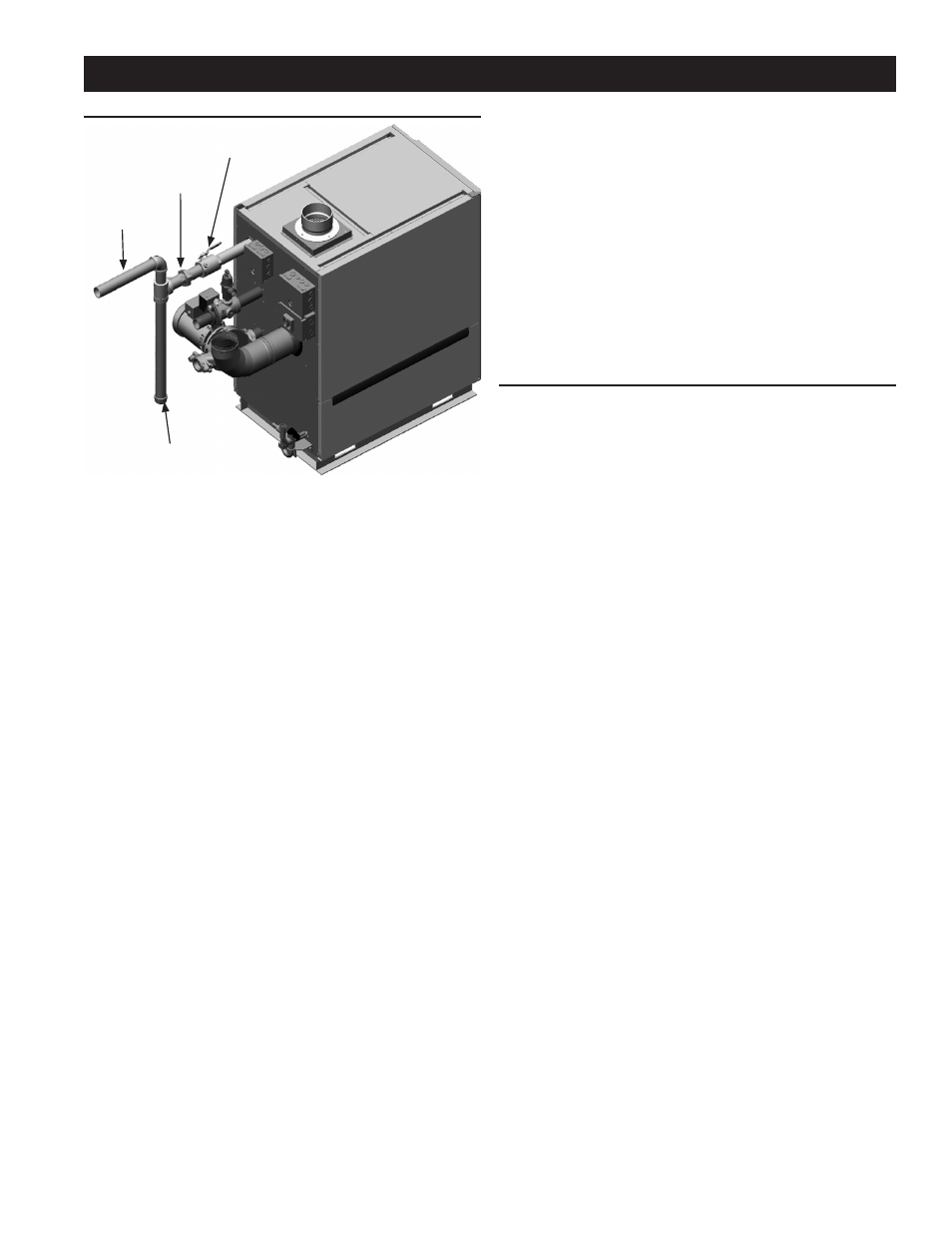

FIGURE 40. GAS SUPPLY PIPING

MAIN GAS SHUTOFF VALVE

SEDIMENT TRAP

UNION

GAS SUPPLY