Control system, Burner control system – A.O. Smith 3400 User Manual

Page 45

45

4. 24VAC:

• Output control of gas control valve (Pilot and Main) and

External Ignition Transformer.

• Digital inputs for room limit control, high limit control, Gas

pressure switch, low water cutoff.

5. External spark transformer.

6. Flame Sensor.

7. Test jacks for flame signal measurement from a flame sensor.

8. Alarm Output.

COMMUNICATIONS AND DISPLAYS

Two modes of communications are available to the R7910.

1. The R7910 has two RS485 communication ports for

ModBus that allows for interfacing to one or all R7910s of

a system and presents them individually to the user. The

S7999D System Operator interface is a color touchscreen

display used for configuration and monitoring of the R7910A.

Though configuration can be done through the display, it is

not recommended as all the parameters are pre-configured

by the manufacturer. Any custom configuration required by

the field should be done in consultation with the A. O. Smith

qualified service technician. Control Operation and display

status in both test and graphical modes can be shown along

with the ability to setup. The R7910 can also be remotely

reset through the S7999D display.

2. Either ModBus RS485 communication port can be used to

allow configuration and status data to be read and written

to the R7910. Support a Master S7999D or a Building

Automation master to control the R7910 to respond to

a single ModBus address to service the requests of the

ModBus master in a Lead/Lag arrangement.

SPECIFICATIONS

1. Electrical Ratings:

Operating voltage

• 24VAC (20 to 30 VAC, 60 Hz ±5%)

• 30 amps (Single Heat Exchanger)

• 60 amps (Double Heat Exchanger)

Connected Load for Valve and annunciator functions:

• 24VAC, 60Hz

• 120VAC (+10%/-15%), 60Hz (±5%)

• Model Specific

2. Corrosion:

• R7910A must not be used in a corrosive environment.

3. Operating Temperature: -4°F to 150°F (-20°C to 66°C)

4. Storage/Shipping Temperature: -40°F to 150°F (-40°C to

66°C).

5. Humidity:

• Up to 95% Relative Humidity, noncondensing at 104°F for

14 days. Condensing moisture may cause safety shutdown.

6. Vibration: 0.0 to 0.5g Continuous (V2 level)

7. Enclosure: Nema 1/IP40.

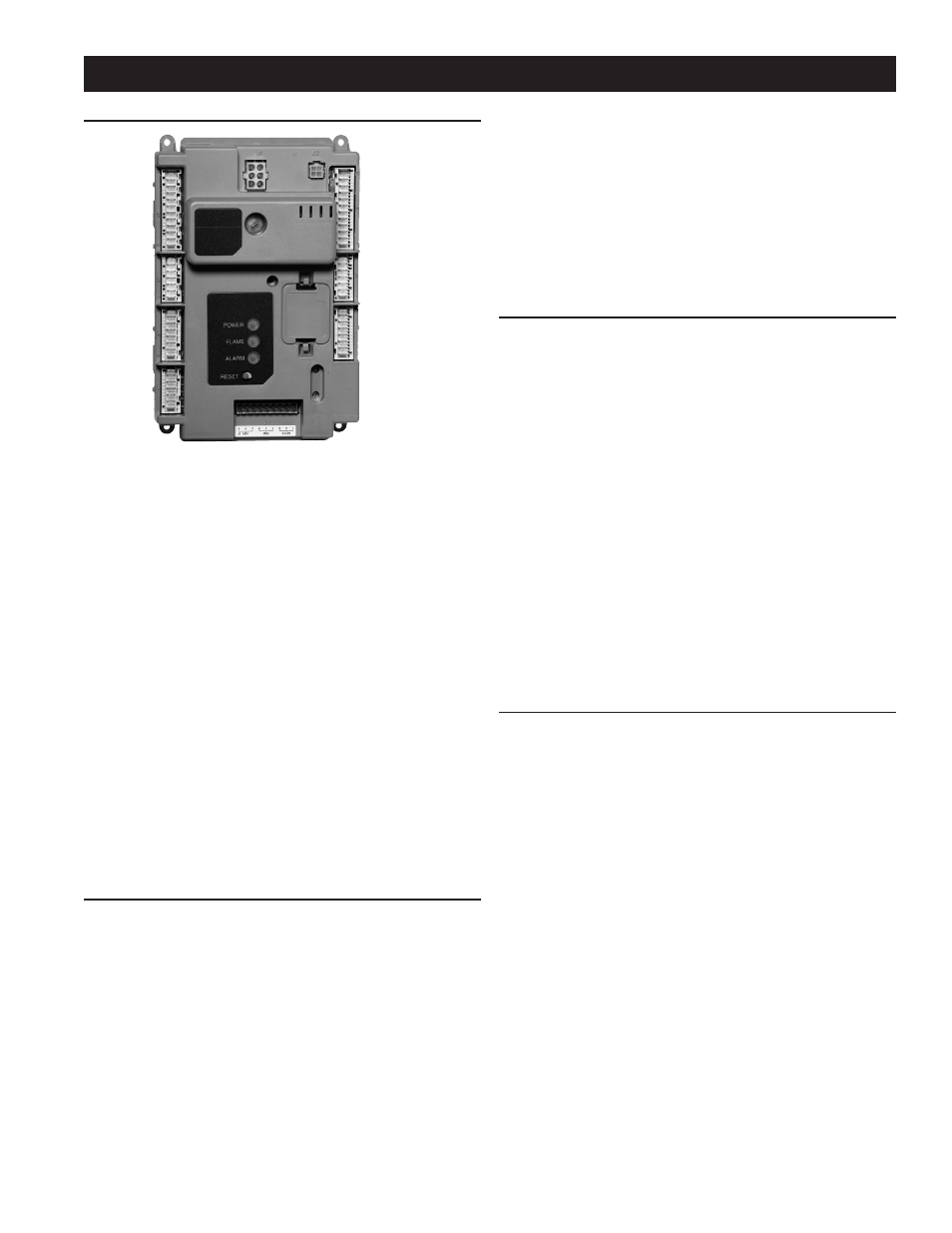

CONTROL SYSTEM

BURNER CONTROL SYSTEM

FIGURE 46. R7910A1138 CONTROL SYSTEM

The R7910A1138 is a burner control system that provide

heat control, flame supervision, circulation pump control,

fan control, boiler control sequencing, and electric ignition

function. It will also provide boiler status and error reporting.

Multiple boilers can be joined together to heat a system instead

of a single, larger burner or boiler. Using boilers in parallel is

more efficient, costs less, reduces emissions, improves load

control, and is more flexible than the traditional large boiler.

Control System consists of:

• R7910A1138 Control Device.

• S7999D Touchscreen Display—required for setup and

ModBus communication but not required for the system

to operate once the R7910A1138 is programmed.

• S7910A Local Keyboard Display Module.

• Flame Sensor .

• Temperature Sensor, NTC Type 10KΩ at 77°F (25°C) or

12KΩ at 77°F (25°C).

• Limit Sensor, NTC Type 10KΩ at 77°F (25°C).

• 24V Digital I/O.

OVERVIEW

Functions provided by the R7910A1138 include automatic boiler

sequencing, flame supervision, system status indication, firing

rate control, load control, CH/DHW control, limit control, system

or self-diagnostics and troubleshooting.

The R7910 maximum version of the controller offers:

1. NTC-temperature sensor for:

• Outlet Limit And Temperature.

• Stack Temperature Limit and Temperature.

• Inlet Temperature.

• Outdoor Temperature (R7910 only).

2. Modulating output PWM-driven rotation speed controlled

DC-fan for optimal modulation control.

3. Three Pump Outputs with 5 selectable operation modes.