A.O. Smith 3400 User Manual

Page 67

67

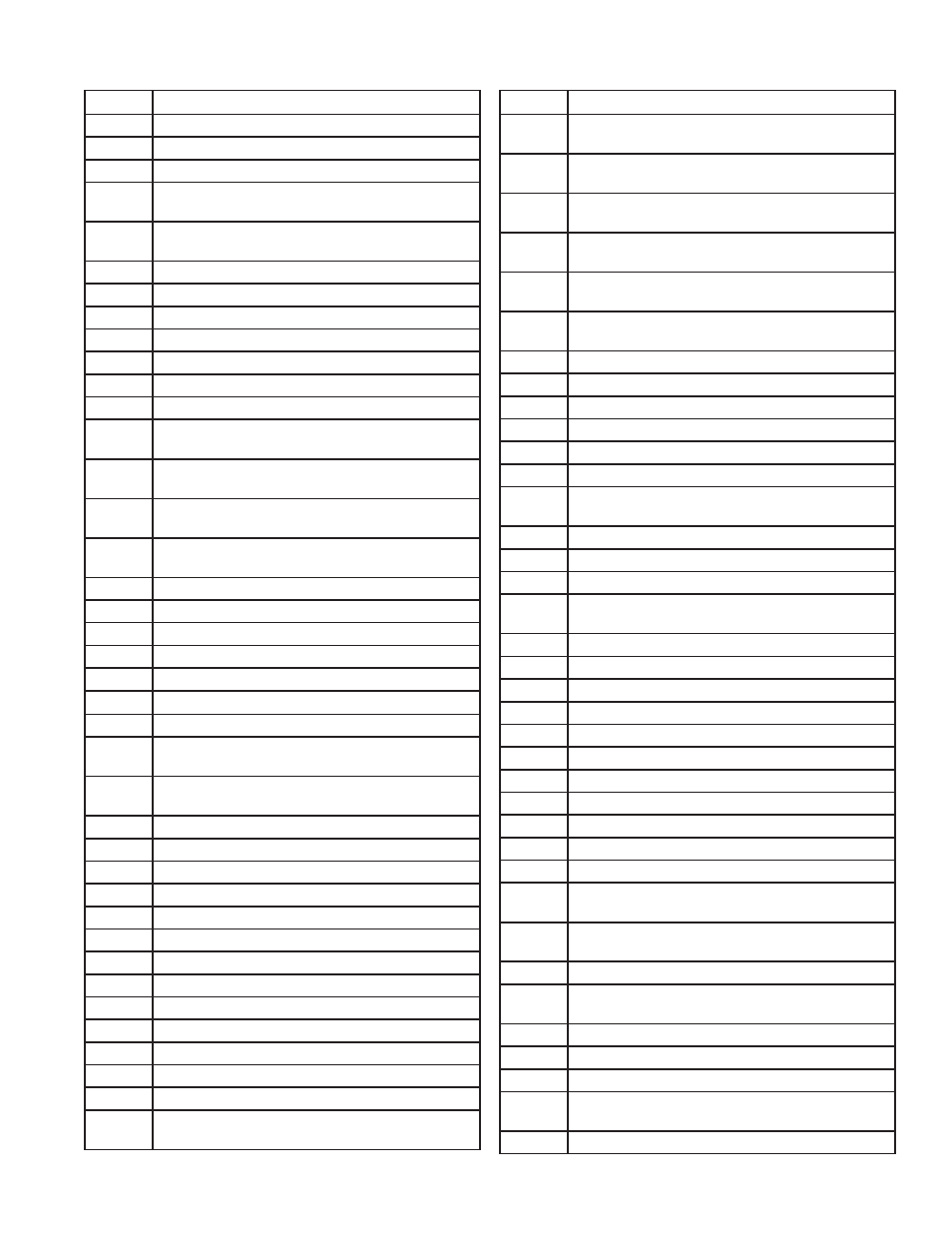

CODE

DESCRIPTION

37

Program Module application parameter revision

differs from application processor

38

Program Module safety parameter revision differs

from safety processor

39

PCB incompatible with product contained in

Program Module

40

Parameter PCB in Program Module is too large for

product

41

Range PCB in Program Module was too large for

product

42

Alert PCB in Program Module was too large for

product

43

IAS start check was forced on due to IAS enabled

System Operation Faults

44

Low voltage was detected in safety processor

45

High line frequency occurred

46

Low line frequency occurred

47

Invalid subsystem reset request occurred

48

Write large enumerated Modbus register value

was not allowed

49

Maximum cycle count was reached

50

Maximum hours count was reached

51

Illegal Modbus write was attempted

52

Modbus write attempt was rejected (NOT

ALLOWED)

53

Illegal Modbus read was attempted

54

Safety processor brown-out reset occurred

55

Application processor watchdog reset occurred

56

Application processor brown-out reset occurred

57

Safety processor watchdog reset occurred

58

Alarm was reset by the user at the control

Demand/Rate Command Faults

59

Burner control firing rate was > absolute max rate

60

Burner control firing rate was < absolute min rate

61

Burner control firing rate was invalid, % vs. RPM

62

Burner control was firing with no fan request

63

Burner control rate (nonfiring) was > absolute max

rate

64

Burner control rate (nonfiring) was < absolute min

rate

65

Burner control rate (nonfiring) was absent

66

Burner control rate (nonfiring) was invalid, %

vs.RPM

67

Fan off cycle rate was invalid, % vs. RPM

68

Setpoint was overridden due to sensor fault

69

Modulation was overridden due to sensor fault

70

No demand source was set due to demand priority

conflicts

71-73

RESERVED

CODE

DESCRIPTION

EE Management Faults

0

None (No alert)

1

Alert PCB was restored from factory defaults

2

Safety configuration parameters were restored

from factory defaults

3

Configuration parameters were restored from

factory defaults

4

Invalid Factory Invisibility PCB was detected

5

Invalid Factory Range PCB was detected

6

Invalid range PCB record has been dropped

7

EEPROM lockout history was initialized

8

Switched application annunciation data blocks

9

Switched application configuration data blocks

10

Configuration was restored from factory defaults

11

Backup configuration settings was restored from

active configuration

12

Annunciation configuration was restored from

factory defaults

13

Annunciation configuration was restored from

backup

14

Safety group verification table was restored from

factory defaults

15

Safety group verification table was updated

16

Invalid Parameter PCB was detected

17

Invalid Range PCB was detected

System Parameter Errors

18

Alarm silence time exceeded maximum

19

Invalid safety group verification table was detected

20

Backdoor Password could not be determined

21

Invalid safety group verification table was not

accepted

22

CRC errors were found in application configuration

data blocks

23

Backup Alert PCB was restored from active one

24

RESERVED

25

Lead Lag operation switch was turned OFF

26

Lead Lag operation switch was turned ON

27

Safety processor was reset

28

Application processor was reset

29

Burner switch was turned OFF

30

Burner switch was turned ON

31

Program Module (PM) was inserted into socket

32

Program Module (PM) was removed from socket

33

Alert PCB was configured

34

Parameter PCB was configured

35

Range PCB was configured

36

Program Module (PM) incompatible with product

was inserted into socket

TABLE 23. ALERTS