A.O. Smith 3400 User Manual

Page 19

19

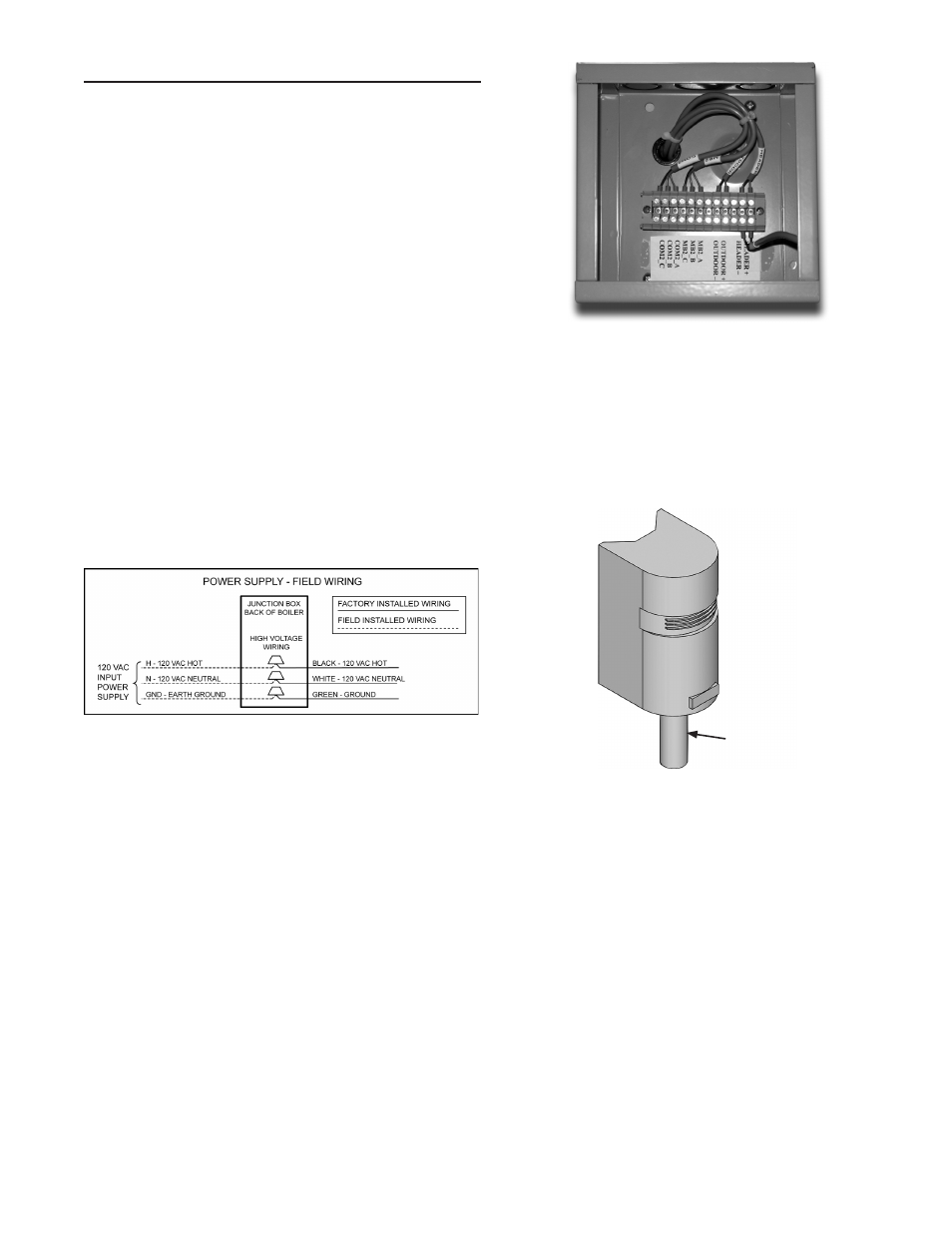

FIELD WIRING

120 VAC POWER SUPPLY WIRING

A dedicated, single phase, 30-60 amp (refer to Table 5 on Page

8) circuit breaker with a grounded neutral should be provided to

supply power to the boilers. Use #10 AWG wire for the 120 VAC

power supply to the boiler. All 120 VAC power supply connections

must be made as shown in Figure 14. These connections

should be made at the rear of the unit where a wiring junction

box is provided. Field installed power supply wiring to the boiler

should be installed in conduit. This conduit and wiring should

be separate from any other conduit/wiring to guard against EMI

(electromagnetic interference).

POWER SUPPLY CHECK

To reduce the possibility of electrical interference with the boiler’s

control system the power supply voltage, polarity and ground must

be checked. Using an AC volt meter check the 120 VAC power

supply wiring from the breaker prior to making power supply

connections at the boiler. Confirm the power supply voltage &

polarity are correct and that an adequate ground connection is

present by performing the three voltage tests below. See Figure

Confirm RMS voltage between:

•

H and GND = 108 VAC minimum, 132 VAC maximum.

•

N and H = 108 VAC minimum, 132 VAC maximum.

•

N and GND = < 1 VAC maximum.

FIGURE 14. FIELD WIRING

LOW VOLTAGE CONTROL WIRING

1. Header Terminals: In case of Hydronic Boilers, the header

terminals are connected to the hydronic loop header sensor.

Whereas in case of Hot water Boilers the header terminals

are connected to the tank sensor where the temperature can

2. Outdoor Terminals: In case of Hydronic Boilers, they are

connected to the outdoor sensors. But in case of Hot water

Boilers, they are not connected. See Figure 15. The outdoor

sensors must be mounted with cable inlet facing down

as shown in Figure 16. The maximum length of the wire

connecting from the boiler to the outdoor sensor must be no

more than 50 feet (15.2 m).

3. MB2 and COM2 terminals are meant for building

management systems.

All low voltage control wiring connections must be made as

shown in Figure 14. These connections should be made at the

rear of the unit where a wiring junction box is provided. Field

installed wiring inside 1/2 inch conduit is installed between the

junction box on the back of the boiler and the temperature probe

and/or field supplied external control being used. This conduit

and wiring should be separate from any other conduit/wiring to

guard against EMI (electromagnetic interference).

The outdoor sensor must be mounted in a shaded location, to

avoid direct sunlight. It must be at least 3 feet (0.9 m) away from

any exhaust, dryer, bathroom or other building vents. It must be

located on the north side of the building, above the expected

snow line where ice and debris cannot cover it.

NOTE: By default the "Outdoor Reset Function" is disabled in the

Control panel, it can be turned ON from the master boiler under

lead lag settings. Once turned ON the outdoor sensor becomes

active and senses temperature, until then it remains idle even

though connected to the back of the boiler.

FIGURE 15. LOW VOLTAGE CONTROL WIRING

FIGURE 16. OUTDOOR SENSOR

CABLE INLET