A.O. Smith 3400 User Manual

Page 18

18

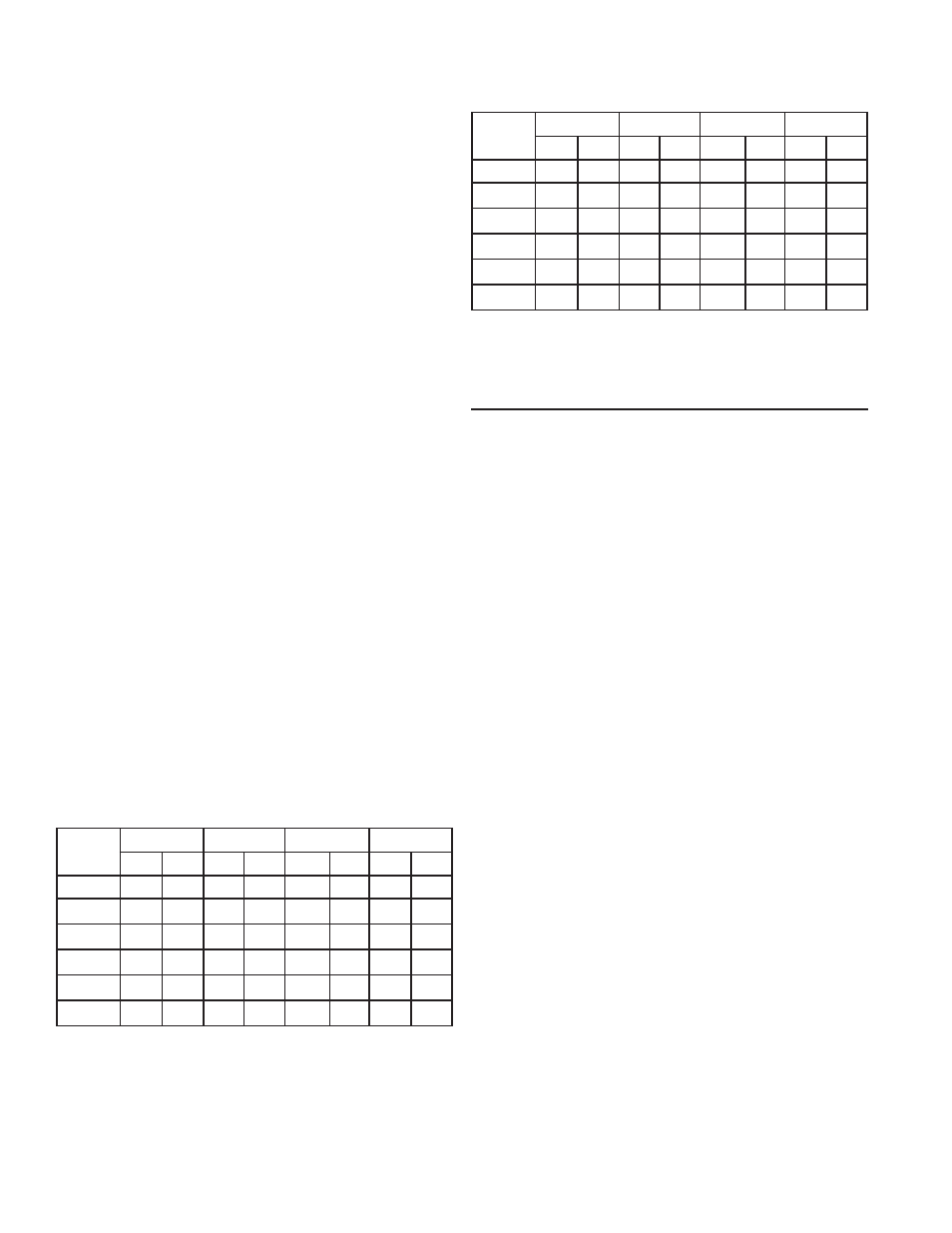

TABLE 8.

SINGLE UNIT INSTALLATION, SUGGESTED GAS PIPE

SIZING. MAXIMUM EQUIVALENT PIPE LENGTH (IN FEET).

BTU

Input

2”

2-1/2”

3”

4”

Nat

Pro

Nat

Pro

Nat

Pro

Nat

Pro

920,000

125

200

200

-----

-----

-----

-----

-----

1,300,000

80

175

175

-----

-----

-----

-----

-----

1,700,000 40

100

100

-----

-----

-----

-----

-----

1,999,900

30

80

80

200

200

-----

-----

-----

2,600,000 20

50

50

125

150

-----

-----

-----

3,400,000 10

30

30

70

90

200

-----

-----

Natural gas 1000 Btu/ft^

3

, 0.63 specific gravity

@

0.5 in. w.c. pressure drop.

Propane gas 2500 Btu/ft^

3

, 1.50 specific gravity

@

0.5 in. w.c. pressure drop.

CORROSIVE MATERIALS AND CONTAMINATION

SOURCES

Products to avoid: (Not all inclusive list)

• Spray cans containing chloro/fluorocarbons

• Permanent wave solutions

• Chlorinated waxes/cleaners

• Chlorine-based swimming pool chemicals

• Calcium chloride used for thawing

• Sodium chloride used for water softening

• Refrigerant leaks

• Paint or varnish removers

• Hydrochloric acid/muriatic acid

• Cements and glues

• Antistatic fabric softeners used in clothes dryers

• Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

• Adhesives used to fasten building products and other

similar products

Areas likely to have contaminants:

• Dry cleaning/laundry areas and establishments

• Swimming pools

• Metal fabrication plants

• Beauty shops

• Refrigeration repair shops

• Photo processing plants

• Auto body shops

• Plastic manufacturing plants

• Furniture refinishing areas and establishments

• New building construction

• Remodeling areas

Common household products, pool and laundry products may

contain fluorine or chlorine compounds. When these chemicals

come in contact with the boiler, they react and can form strong

acids. The acid can spoil the boiler wall, causing serious damage

and may result in flue gas spillage or boiler water leakage into

the building.

If the above mentioned contaminants and corrosive materials

chemicals are present near the location of the boiler, make sure

to remove the boiler permanently or relocate air inlet and vent

terminations to other areas.

Fittings and unions in gas line must be of metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases. The boiler and its gas connection must be leak

tested before placing the boiler in operation.

GAS SUPPLY LINE SIZING

The gas piping installation must be capable of supplying the

maximum probable gas demand without excessive pressure loss.

Depending on local practices, the ALLOWABLE PRESSURE

LOSS between the gas meter, or service regulator and each

appliance is generally 0.3 or 0.5 inches of water column (0.075

or 0.124 kPa).

For single boiler installation, refer to Table 7 and Table 8 to size

iron pipe or equivalent gas supply line size to be used with single

unit.

For multiple boiler installation or installations of a single boiler

with other gas appliances, please refer to Table 9 and Table 10

on Page 20 to size iron pipe or equivalent gas supply line. These

tables are taken from the current edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

• Table 9 is based on a pressure drop of 0.5 inches water

column (0.124 kPa), and a gas with a specific gravity of

0.60 and a heating value of 1,000 BTU/ft

3

, approximately

that of Natural Gas.

• Table 10 is based on a pressure drop of 0.5 inches water

column (0.124 kPa), and a gas with a specific gravity of

1.53 and a heating value of 2,500 BTU/ft3, approximately

that of Propane Gas.

Where it is necessary to use more than the average number of

fittings (i.e., elbows, tees and valves in gas supply line) use a

pipe larger than specified to compensate for increased pressure

drop.

Table 7 and Table 8 shows the maximum equivalent gas pipe

length for a single unit installation. It does not take into account

other appliances that may be connected to the gas line.

For installation of multiple units, or instances where several

appliances are connected to the same line, use Table 9 and

TABLE 7.

SINGLE UNIT INSTALLATION, SUGGESTED GAS PIPE

SIZING. MAXIMUM EQUIVALENT PIPE LENGTH (IN FEET).

BTU

Input

2”

2-1/2”

3”

4”

Nat

Pro

Nat

Pro

Nat

Pro

Nat

Pro

920,000

70

150

175

-----

-----

-----

-----

-----

1,300,000

40

100

100

200

-----

-----

-----

-----

1,700,000 20

60

70

150

200

-----

-----

-----

1,999,900

20

50

50

100

150

-----

-----

-----

2,600,000 10

30

30

70

90

200

-----

-----

3,400,000 -----

-----

20

40

50

125

200

-----

Natural gas 1000 Btu/ft^

3

, 0.60 specific gravity

@

0.3 in. w.c. pressure drop.

Propane gas 2500 Btu/ft^

3

, 1.50 specific gravity

@

0.3 in. w.c. pressure drop.