Condensate disposal – A.O. Smith 3400 User Manual

Page 38

38

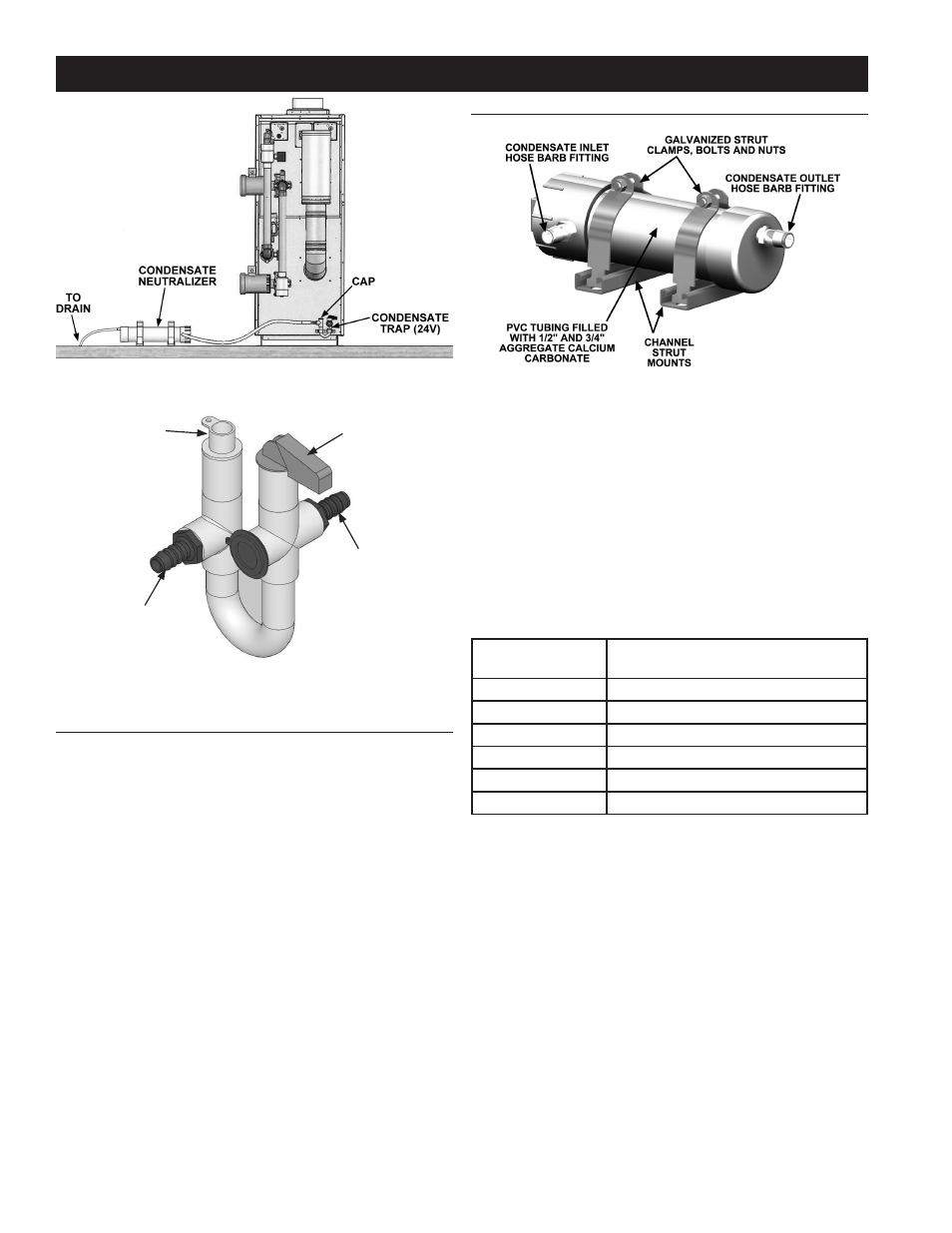

CONDENSATE NEUTRALIZER

The condensate drains from the boiler have pH levels between

4.3 and 5.0. The pH measurement of a fluid is an indicator of

the acidity or alkalinity. Neutral fluids have pH of 7.0. Acid fluids

have pH below 7. Some local codes may require the use of a

condensate neutralizer to raise the pH level of the condensate

leaving the boiler. The condensate neutralizer be must installed

between the boiler and the drain and must be installed lower

than the outlet of the condensate trap as shown in Figure 37. The

Condensate Neutralizer Kit model must be selected with respect

to the boiler's output as mentioned in the Table 16.

TABLE 16. CONDENSATE NEUTRALIZER KIT MODELS

MODELS

(XB)

A. O. SMITH CONDENSATE

NEUTRALIZER KIT NUMBERS

1000

9007961005

1300

9007962005

1700

9007962005

2000

9007962005

2600

9007963005

3400

9007963005

CONDENSATE DISPOSAL

CONDENSATE TRAP

Installation of the Condensate Trap must conform with the

instructions in this manual and local building codes. Condensate

Neutralizer Kits are available. Contact your distributor or Service

Agency. Do not remove, modify or alter the factory installed

condensate trap. Install a commercially available neutralizing kit

if required by the local codes.

The boiler is factory fitted with a 24V condensate trap connected

to the controller. For safety reasons, if the condensate drain is

blocked, the control system will turn off all the firing burners and

bring the boiler to a safe shut down. If there is an air blockage

in the line, vent out the air by removing the cap. Cap acts as an

air vent for releasing any air block on down stream condensate

line. Flexible silicon hose connect from the trap through the

Condensate Neutralizer to the drain.

Due to the highly efficient operation of this unit, condensate is

formed during operation and must be removed by the conden-

sate drain systems. Inspect the condensate drains and tubes at

least once a month and insure they will allow the free flow of

condensate at all times. The system must be inspected more

frequently in cold weather if the drain system is located in an

area, such as along the floor, where freezing tempera tures are

likely to occur. The conden sate drain system must be protected

against freezing. Contact a qualified service technician to inspect

and correct the condition if freezing of the conden sate lines is a

problem.

FIGURE 37. CONDENSATE DISPOSAL SYSTEM

FIGURE 38. CONDENSATE TRAP

FIGURE 39. CONDENSATE NEUTRALIZER

ELECTRICAL SWITCH AND FLOAT

CONDENSATE INLET

FROM THE BOILER

CAP

CONDENSATE OUTLET