Control components – A.O. Smith 3400 User Manual

Page 13

13

FIGURE 7. LOW/HIGH GAS PRESSURE SWITCH

GAS CONTROL VALVE

The gas control valve is a normally closed servo regulated gas

control valve. The valve opens only when energized by the

burner control and closes when the power is removed. The

burner control supplies 24 volts to the gas control valve during

operation.

FIGURE 8. GAS CONTROL VALVE

WATER FLOW SWITCH

The water flow switch activates when sufficient water flow has

been established. Switch will not close when water flow is not

present.

FIGURE 9. WATER FLOW SWITCH

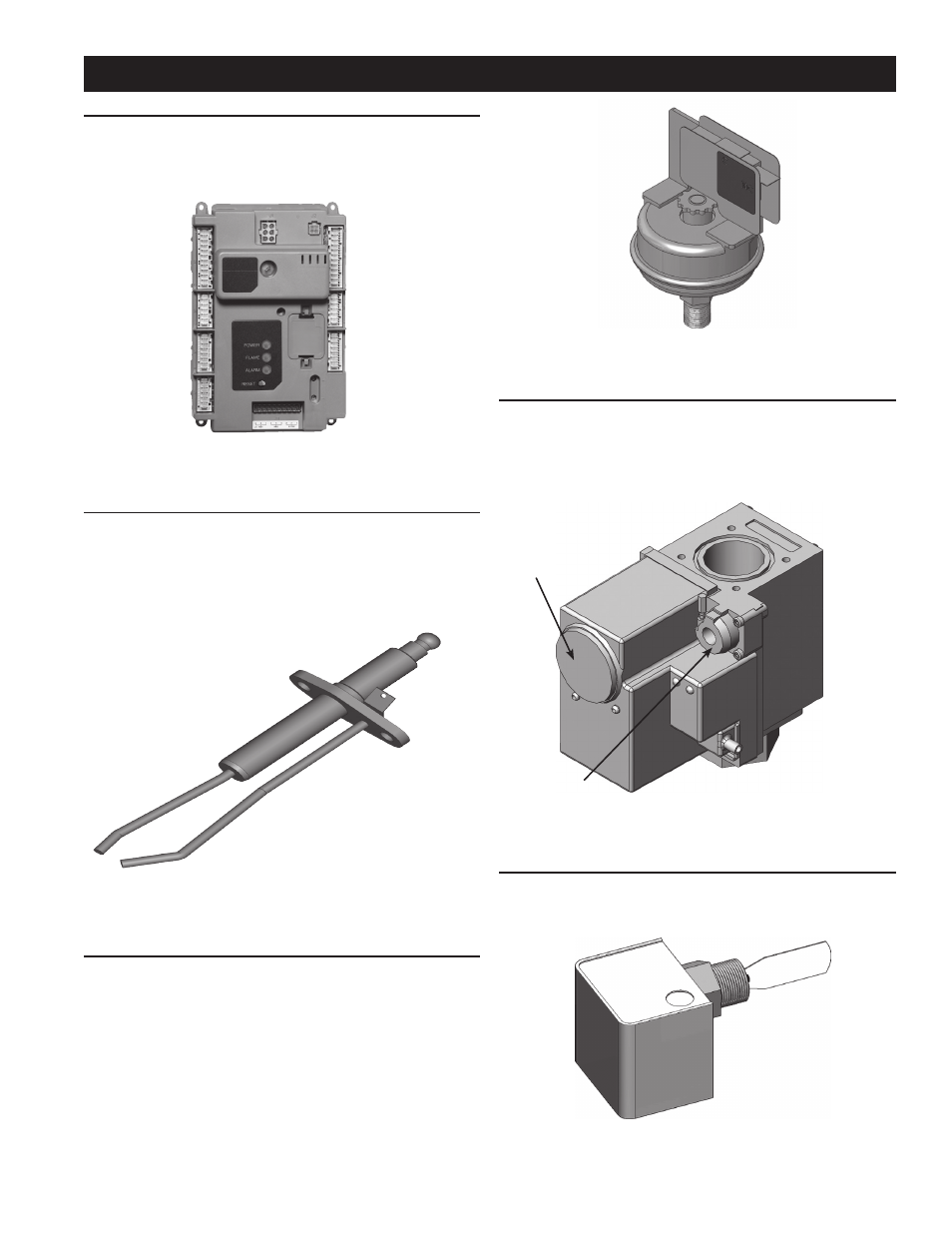

THE CONTROL SYSTEM

The R7910A1138 is a burner control system that provides heat

control, flame supervision, circulation pump control, fan control,

boiler control sequencing, and electric ignition function. It will

also provide status and error reporting.

FIGURE 5. BURNER CONTROL SYSTEM

SPARK IGNITER

The spark igniter is a device that ignites the main burner. When

power is supplied to the igniter electrode, an electric arc is

created between the electrode and the ground terminal which

ignites the main burner.

FIGURE 6. SPARK IGNITER

LOW/HIGH GAS PRESSURE SWITCH

This XB boiler is equipped with a low gas pressure switch which

meets the CSD-1 code requirements.

The Low Gas Pressure Switch is normally open and remains

open if the pressure is below the preset pressure. It closes as

soon as the gas supply pressure is above the minimum supply

pressure.

The High Gas Pressure Switch is normally closed and is used to

detect excessive gas pressure.

CONTROL COMPONENTS

H I G H F I R I N G

RATE SETTING

L O W F I R I N G

RATE SETTING