2 introduction, 1 theory of operation, Introduction – LumaSense Technologies BoilerSpection-SD User Manual

Page 9: Theory of operation

BoilerSpection HD/SD Manual

Introduction 9

2 Introduction

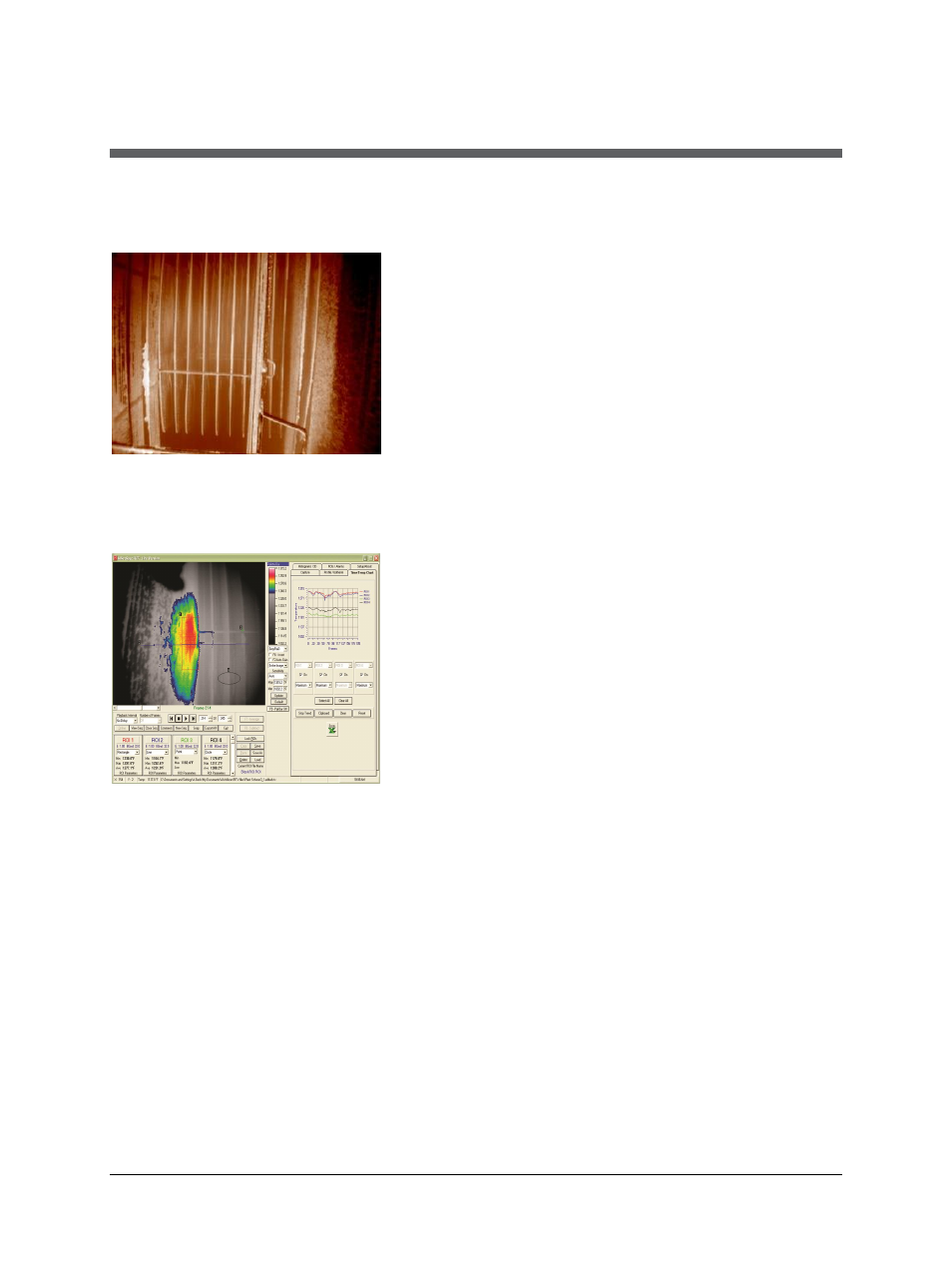

Figure 1: Pendant Section Inside a

Coal-Fired Boiler monitored using

the BoilerSpection system

Figure 2: Screenshot of LumaSense

Analysis Software

The LumaSense BoilerSpection™ system is a comprehensive

turnkey solution that provides continuous imaging inside

boilers and furnaces. The core components that comprise the

system are the 320x240 IR imager filtered at 3.9 µm, a

borescope lens, protective hardware that includes cooling,

and an auto-retract device with controls.

This enables continuous conditions monitoring, allowing:

Reduced cleaning frequency

Focused cleaning in high deposit areas

Extended boiler tube life

Identification of process abnormalities

Automated inspections with Radiometric Imaging

Increased boiler efficiency and output

Monitoring and analysis of furnace process changes

(i.e., in fuel, coal, burners, maintenance, etc.)

Archiving of images and video for comparative

analysis

LumaSense engineering staff and sales consultants follow a

system approach to online thermal processing control. They

have specific expertise and technical skills required to specify

and integrate the appropriate application-specific imaging

components with your existing control platform. LumaSense

takes the ultimate responsibility for the thermal imaging

system, meeting your design specifications, and saving you

time, cost, and allocation of in-house resources.

2.1 Theory of Operation

Thermal imaging, a technology originally developed for military surveillance, has been adapted by

LumaSense thermal imaging cameras for a wide range of industrial process control applications.

These applications include continuous metals casting, furnace refractory monitoring, rotary kilns,

boilers, incinerators, critical vessel monitoring, and advanced materials processing.

Thermal imaging systems convert infrared radiation into digital temperature data which we can

measure, visualize, and quantify with a high degree of accuracy. An infrared imaging system

consists of an array detector, electronics, infrared optics and filters, computer for data collection,

and software for automation and analysis. For industrial applications, LumaSense adds protective

mechanical hardware, custom optical filters, and automation software. Variations in the infrared

emission from the surface of a material appear as variations of light and shade, or different colors.

With our software, the user of the system can store and manipulate the images for analysis.