Chapter three wiring, Chapter 3: wiring, Torque guidelines – Watlow Power Series Rev H User Manual

Page 13: Wiring the power series controller

Chapter Three

Wiring

Wiring the Power Series Controller

Wiring options depend on the model number. Check the terminal designation stickers on the

right side of the controller and compare your model number to those shown here and with

the model number breakdown in the Appendix (page A.10) of this manual.

Chapter 3 illustrates how to wire the inputs and outputs for all options. Refer to Figure 3.1

for terminal torque guidelines.

Torque Guidelines

•

Properly torque terminals by holding for 30 seconds to allow for wires to settle and

minimize loosening due to cold flow.

•

Re-torque all terminals after 48 hours.

•

Establish a maintenance program to re-torque line and load terminations every 3-6

months.

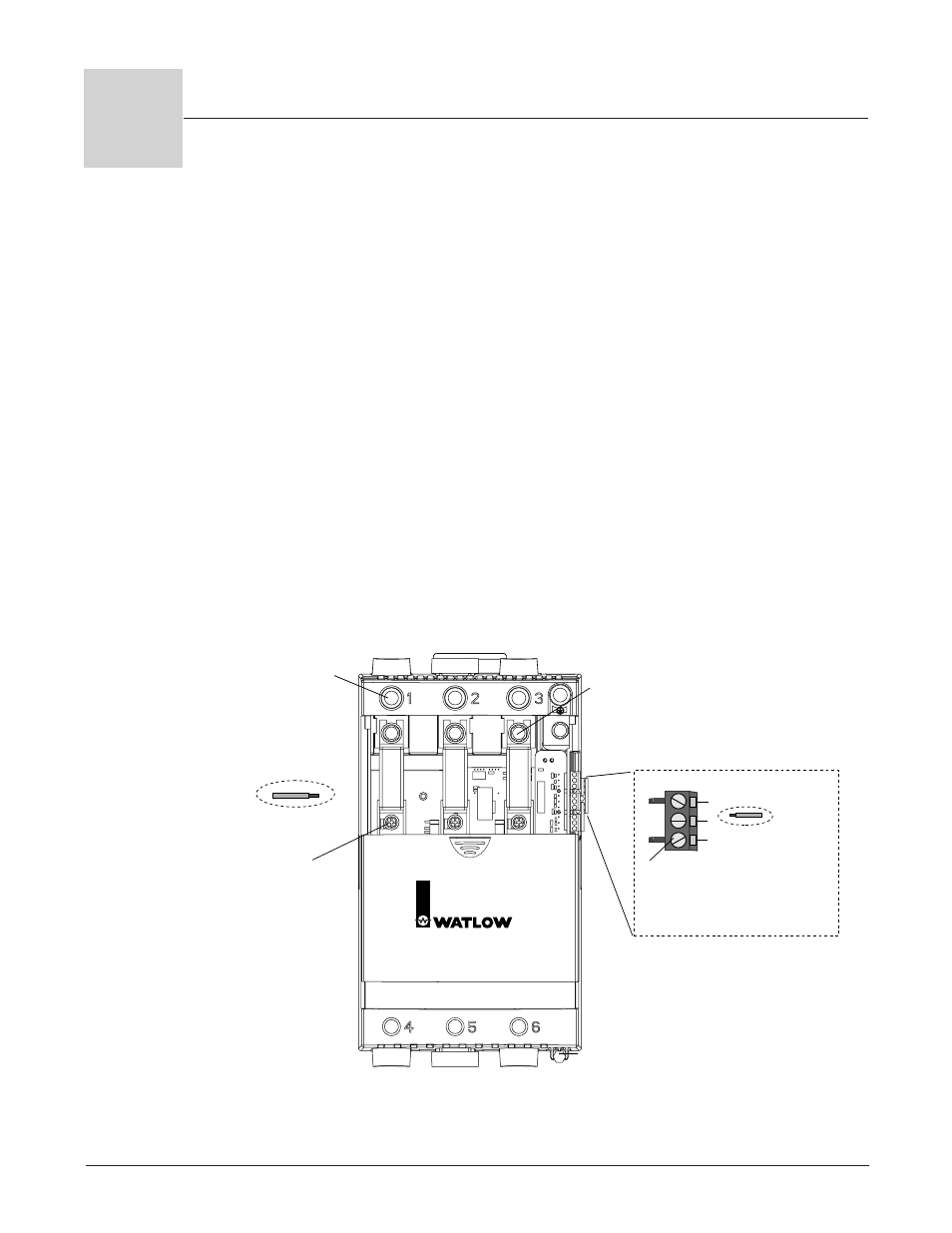

Figure 3.1 — Torque and wire stripping.

Terminals 1 - 6

and Ground Lug

Torque to

180 in.-lbs.

(20 Nm.)

with 3/8 inch

Allen wrench

provided.

Strip wires

1-1/8 inch (30mm)

#3 Phillips

Screws for Fuse

Mounting

For models

PXX-F20X-XXXX

PXX-N20X-XXXX

Torque to

26 in.-lbs. (2.93 Nm.)

For models

PXX-F25X-XXXX

PXX-N25X-XXXX

PXX-F30X-XXXX

PXX-N30X-XXXX

PXX-F35X-XXXX

Torque to

44 in.-lbs. (4.95 Nm.)

5/16 inch Bolts

for Fuse Mounting

Torque to 44 in.-lbs.

(4.95 Nm.)

Strip wires

0.24 in. (6mm)

Torque to 8 in.-lbs. (0.9 Nm.) using

a 1/8 inch (2.5 mm) blade screwdriver.

Accepts 12-22 AWG or 2 No. 22-18

AWG wires.

Controller Connectors

Allen Wrench

(Flat surface must be against the case.)

Fuse

Fuse

Fuse

Power Series

Solid State Power Control

3

W i r i n g , C h a p t e r 3

Wa t l o w P o w e r S e r i e s

I

3 . 1