IAI America RCA2-TW4N User Manual

Page 64

56

7. Operation

[4] Moment

Check whether the operation is available by [2] moment, [4] acceleration, [5] loading capacity,

and [6] overhang.

Static moment (M1) calculation

Static moment equation

M1 = W x L x 9.8/1000 (Nm); L (mm): Distance from the operation point to load center of gravity

Stroke consideration: L = T + Hn + stroke (Patterns A and B)

No stroke consideration: L = T + Hn (Patterns C, D, and E)

Use Figure 2 and Table 2 to select an Hn measurement based on the installation orientation of the

load.

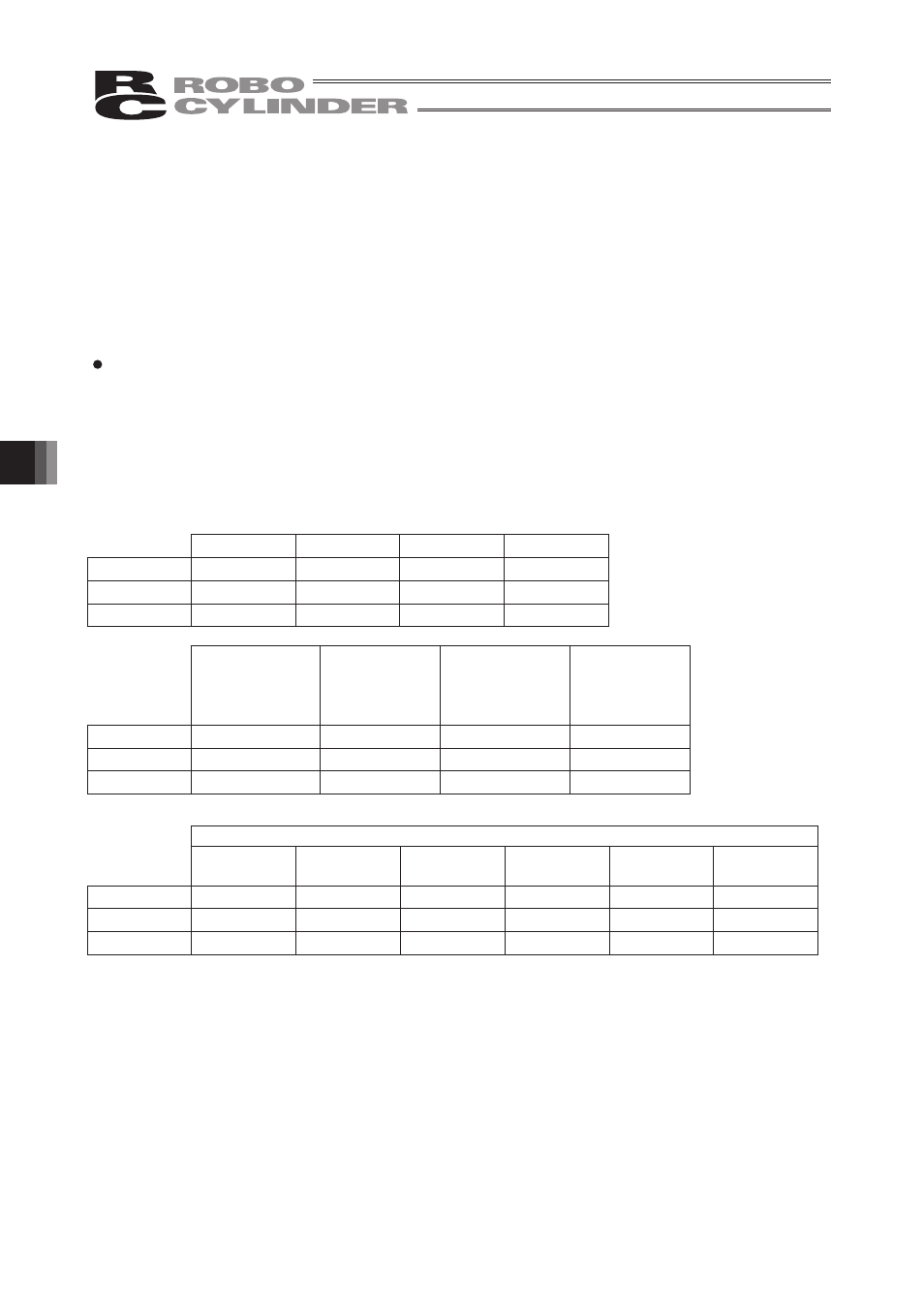

Table 2: Hn measurement (distance from the operation point to end of table)

TA4

TA5

TA6

TA7

H1 (mm)

30

49

54.5

61.5

H2 (mm)

20

25

30

37

H3 (mm)

11.5

13.5

15.5

17.5

TCA3N, TFA3N

(Slide screw)

(Ball screw)

TWA3N

(Slide screw)

(Ball screw)

TCA4N, TFA4N

(Slide screw)

(Ball screw)

TWA4N

(Slide screw)

(Ball screw)

H1 (mm)

64

64

66

66

H2 (mm)

16

25

18

29

H3 (mm)

11

TC3N, TF3N

(Slide screw)

TW3N

(Slide screw)

TC4N, TF4N

(Slide screw)

TW4N

(Slide screw)

TC4N, TF4N

(Ball screw)

TW4N

(Ball screw)

H1 (mm)

H2 (mm)

H3 (mm)

74.5

29

15.5

73.5

19

16

74.5

29

15.5

73.5

19

16

68

25

12.5

71.5

17

16

Ball Guide Type (Option: Model Code BG)

[3] Maximum speed, loading capacity

Check whether the operation is available by [3] maximum speed and [5] loading capacity.

AC Servo motor (RCA2) (Graph 1)

How to decide: You can use any model that has a [3] maximum speed and [4] loading capacity that is within

usage range in the graph.

TCA3NA, TFA3NA

TWA3NA

TCA4NA, TFA4NA

TWA4NA

9.5

10.5

9.5