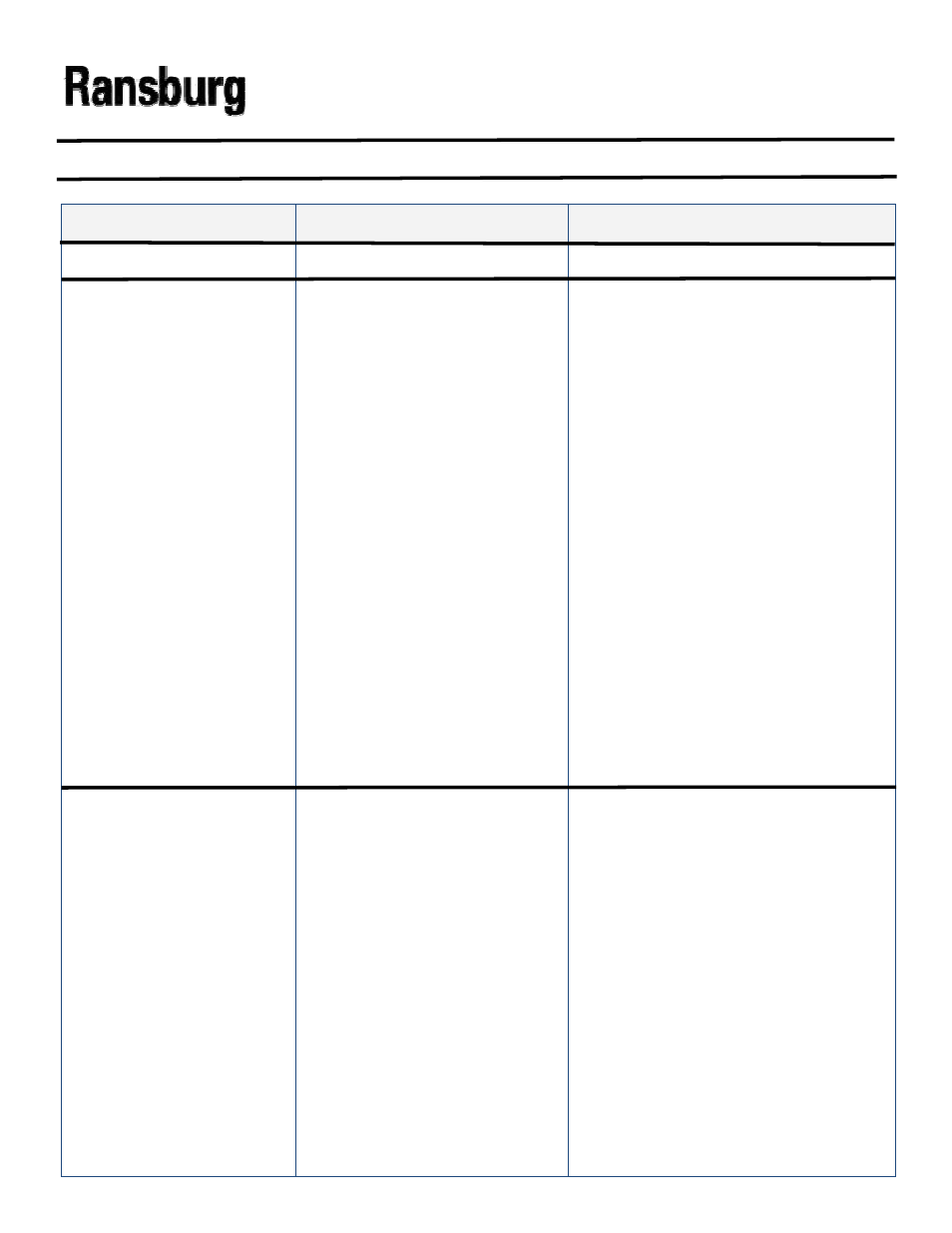

Troubleshooting guide – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 45

45

45

45

45

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Solution

Solution

Solution

Solution

Mechanical

Mechanical

Mechanical

Mechanical

Poor Atomization (See Electrical

Poor Atomization (See Electrical

Poor Atomization (See Electrical

Poor Atomization (See Electrical

troubleshooting)

troubleshooting)

troubleshooting)

troubleshooting)

1. Dirty Bell

1. Dirty Bell

1. Dirty Bell

1. Dirty Bell

1. Clean the bell (see service instruction

1. Clean the bell (see service instruction

1. Clean the bell (see service instruction

1. Clean the bell (see service instruction

‘Solvent Effects on No. 2 Handgun Bell /

‘Solvent Effects on No. 2 Handgun Bell /

‘Solvent Effects on No. 2 Handgun Bell /

‘Solvent Effects on No. 2 Handgun Bell /

Brush Wear”)

Brush Wear”)

Brush Wear”)

Brush Wear”)

2. Feed tube improperly positioned

2. Feed tube improperly positioned

2. Feed tube improperly positioned

2. Feed tube improperly positioned

2. Position as indicated in the “Installation “

2. Position as indicated in the “Installation “

2. Position as indicated in the “Installation “

2. Position as indicated in the “Installation “

section

section

section

section

3. Contact brush worn or improperly

3. Contact brush worn or improperly

3. Contact brush worn or improperly

3. Contact brush worn or improperly

positioned or broken

positioned or broken

positioned or broken

positioned or broken

3. Re

3. Re

3. Re

3. Re----position or replace

position or replace

position or replace

position or replace

4. Chipped bell edge

4. Chipped bell edge

4. Chipped bell edge

4. Chipped bell edge

4. Replace

4. Replace

4. Replace

4. Replace

5. Bell rotation too slow

5. Bell rotation too slow

5. Bell rotation too slow

5. Bell rotation too slow

5. Check the seal is clean ( clean or replace

5. Check the seal is clean ( clean or replace

5. Check the seal is clean ( clean or replace

5. Check the seal is clean ( clean or replace

the outer or PTFE seal. Motor shaft warped

the outer or PTFE seal. Motor shaft warped

the outer or PTFE seal. Motor shaft warped

the outer or PTFE seal. Motor shaft warped

(replace the motor shaft)

(replace the motor shaft)

(replace the motor shaft)

(replace the motor shaft)

6. Paint input exceeds gun atomiza-

6. Paint input exceeds gun atomiza-

6. Paint input exceeds gun atomiza-

6. Paint input exceeds gun atomiza-

tion capacity

tion capacity

tion capacity

tion capacity

6. Reduce the paint delivery and/or use larger

6. Reduce the paint delivery and/or use larger

6. Reduce the paint delivery and/or use larger

6. Reduce the paint delivery and/or use larger

bell.

bell.

bell.

bell.

7. Improper paint mixture

7. Improper paint mixture

7. Improper paint mixture

7. Improper paint mixture

7. Test paint resistance (conductivity). See

7. Test paint resistance (conductivity). See

7. Test paint resistance (conductivity). See

7. Test paint resistance (conductivity). See

solvent section.

solvent section.

solvent section.

solvent section.

8. Bell coating deteriorated, worn,

8. Bell coating deteriorated, worn,

8. Bell coating deteriorated, worn,

8. Bell coating deteriorated, worn,

chipped or dead electrically

chipped or dead electrically

chipped or dead electrically

chipped or dead electrically

8. Replace bell

8. Replace bell

8. Replace bell

8. Replace bell

9. Paint too dry

9. Paint too dry

9. Paint too dry

9. Paint too dry

9. Contact your Ransburg distributor

9. Contact your Ransburg distributor

9. Contact your Ransburg distributor

9. Contact your Ransburg distributor

Insufficient Paint Flow or No

Insufficient Paint Flow or No

Insufficient Paint Flow or No

Insufficient Paint Flow or No

Flow

Flow

Flow

Flow

1. Defective pump or inadequate air

1. Defective pump or inadequate air

1. Defective pump or inadequate air

1. Defective pump or inadequate air

pressure at the paint pressure pot

pressure at the paint pressure pot

pressure at the paint pressure pot

pressure at the paint pressure pot

1. Repair pump or increase pressure

1. Repair pump or increase pressure

1. Repair pump or increase pressure

1. Repair pump or increase pressure

2. Feed tube clogged

2. Feed tube clogged

2. Feed tube clogged

2. Feed tube clogged

2. Follow “Color Change” procedure in te

2. Follow “Color Change” procedure in te

2. Follow “Color Change” procedure in te

2. Follow “Color Change” procedure in te

“Operation “ section.

“Operation “ section.

“Operation “ section.

“Operation “ section.

3. Paint hose clogged

3. Paint hose clogged

3. Paint hose clogged

3. Paint hose clogged

3. Clean with solvent/or air pressure. Replace

3. Clean with solvent/or air pressure. Replace

3. Clean with solvent/or air pressure. Replace

3. Clean with solvent/or air pressure. Replace

worn hose when required.

worn hose when required.

worn hose when required.

worn hose when required.

4. High Viscosity Paint

4. High Viscosity Paint

4. High Viscosity Paint

4. High Viscosity Paint

4. Increase fluid pressure or reduce viscosity.

4. Increase fluid pressure or reduce viscosity.

4. Increase fluid pressure or reduce viscosity.

4. Increase fluid pressure or reduce viscosity.

Cold paint will have higher viscosity.

Cold paint will have higher viscosity.

Cold paint will have higher viscosity.

Cold paint will have higher viscosity.

5. Needle valve clogged

5. Needle valve clogged

5. Needle valve clogged

5. Needle valve clogged

5. Follow “Color Change” procedure in te

5. Follow “Color Change” procedure in te

5. Follow “Color Change” procedure in te

5. Follow “Color Change” procedure in te

“Operation “ section and/or repair valve.

“Operation “ section and/or repair valve.

“Operation “ section and/or repair valve.

“Operation “ section and/or repair valve.

6. Solvent filter clogged

6. Solvent filter clogged

6. Solvent filter clogged

6. Solvent filter clogged

6. Clean ore replace filter. (See “Filter Clean-

6. Clean ore replace filter. (See “Filter Clean-

6. Clean ore replace filter. (See “Filter Clean-

6. Clean ore replace filter. (See “Filter Clean-

ing or Replacement” in “Maintenance” section

ing or Replacement” in “Maintenance” section

ing or Replacement” in “Maintenance” section

ing or Replacement” in “Maintenance” section

7. Applicator fluid passage clogged

7. Applicator fluid passage clogged

7. Applicator fluid passage clogged

7. Applicator fluid passage clogged

7. Follow “Color Change” procedure in te

7. Follow “Color Change” procedure in te

7. Follow “Color Change” procedure in te

7. Follow “Color Change” procedure in te

“Operation “ section or contact you Ransburg

“Operation “ section or contact you Ransburg

“Operation “ section or contact you Ransburg

“Operation “ section or contact you Ransburg

distributor.

distributor.

distributor.

distributor.

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE