Dynamic pressure vs. turbine speed, Dynamic pressure (bar) – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 22

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

22

22

22

22

NOTE

NOTE

NOTE

NOTE

The quality of atomization can be tested by

The quality of atomization can be tested by

The quality of atomization can be tested by

The quality of atomization can be tested by

shooting a “donut” test pattern on a grounded

shooting a “donut” test pattern on a grounded

shooting a “donut” test pattern on a grounded

shooting a “donut” test pattern on a grounded

flat surface at approximately a 15.2 cm (6

flat surface at approximately a 15.2 cm (6

flat surface at approximately a 15.2 cm (6

flat surface at approximately a 15.2 cm (6----inch)

inch)

inch)

inch)

target distance. Coarse atomization may be

target distance. Coarse atomization may be

target distance. Coarse atomization may be

target distance. Coarse atomization may be

caused by excessive fluid delivery (high fluid

caused by excessive fluid delivery (high fluid

caused by excessive fluid delivery (high fluid

caused by excessive fluid delivery (high fluid

pressure or wrong bell size) or improper electri-

pressure or wrong bell size) or improper electri-

pressure or wrong bell size) or improper electri-

pressure or wrong bell size) or improper electri-

cal resistance of the coating material. Adjust pa-

cal resistance of the coating material. Adjust pa-

cal resistance of the coating material. Adjust pa-

cal resistance of the coating material. Adjust pa-

rameters according to atomization quality and

rameters according to atomization quality and

rameters according to atomization quality and

rameters according to atomization quality and

results.

results.

results.

results.

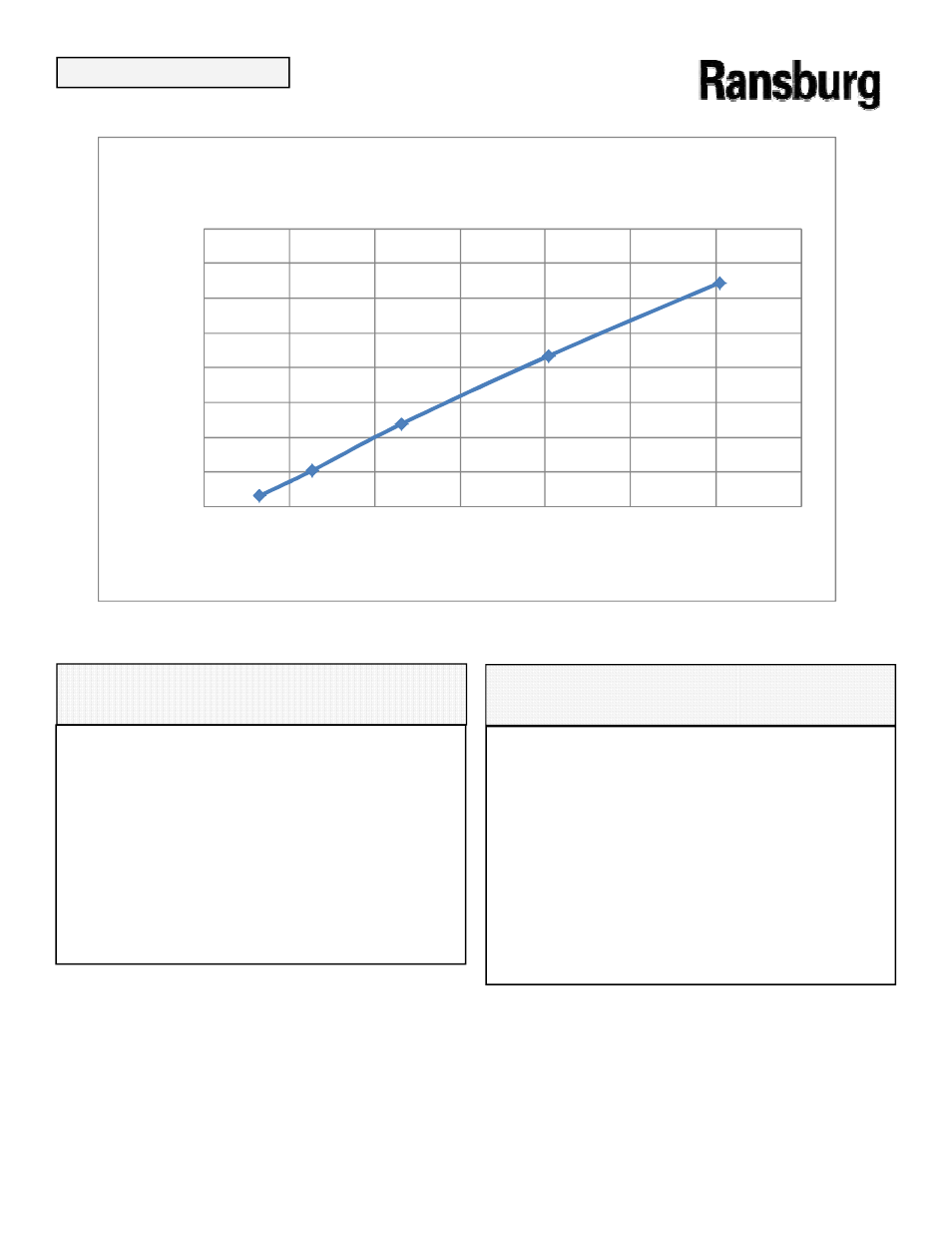

200

300

400

500

600

700

800

900

1000

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

R

o

ta

ti

o

n

a

l

S

p

e

e

d

(

R

P

M

)

Dynamic Pressure (bar)

Dynamic Pressure vs. Turbine Speed

Figure 14: Rotational Bell Speed Versus Dynamic Pressure

Figure 14: Rotational Bell Speed Versus Dynamic Pressure

Figure 14: Rotational Bell Speed Versus Dynamic Pressure

Figure 14: Rotational Bell Speed Versus Dynamic Pressure

7. Pulling the applicator trigger to obtain material

7. Pulling the applicator trigger to obtain material

7. Pulling the applicator trigger to obtain material

7. Pulling the applicator trigger to obtain material

flow, move the No. 2 handgun in a smooth hori-

flow, move the No. 2 handgun in a smooth hori-

flow, move the No. 2 handgun in a smooth hori-

flow, move the No. 2 handgun in a smooth hori-

zontal or vertical line or in a smooth circular mo-

zontal or vertical line or in a smooth circular mo-

zontal or vertical line or in a smooth circular mo-

zontal or vertical line or in a smooth circular mo-

tion, maintaining a constant distance between

tion, maintaining a constant distance between

tion, maintaining a constant distance between

tion, maintaining a constant distance between

the target and the bell surface. (See Ransburg

the target and the bell surface. (See Ransburg

the target and the bell surface. (See Ransburg

the target and the bell surface. (See Ransburg

manual "No. 2 Handgun Spray Techniques".)

manual "No. 2 Handgun Spray Techniques".)

manual "No. 2 Handgun Spray Techniques".)

manual "No. 2 Handgun Spray Techniques".)

NOTE

NOTE

NOTE

NOTE

For an accurate measurement of paint

For an accurate measurement of paint

For an accurate measurement of paint

For an accurate measurement of paint de-

de-

de-

de-

livery with any paint being used, turn the

livery with any paint being used, turn the

livery with any paint being used, turn the

livery with any paint being used, turn the

handgun motor OFF, and remove the bell.

handgun motor OFF, and remove the bell.

handgun motor OFF, and remove the bell.

handgun motor OFF, and remove the bell.

Using a graduated cylinder or beaker and a

Using a graduated cylinder or beaker and a

Using a graduated cylinder or beaker and a

Using a graduated cylinder or beaker and a

stopwatch, trigger the gun and collect the

stopwatch, trigger the gun and collect the

stopwatch, trigger the gun and collect the

stopwatch, trigger the gun and collect the

fluid for one minute. Measure the paint vol-

fluid for one minute. Measure the paint vol-

fluid for one minute. Measure the paint vol-

fluid for one minute. Measure the paint vol-

ume collected to get fluid flow rate per mi-

ume collected to get fluid flow rate per mi-

ume collected to get fluid flow rate per mi-

ume collected to get fluid flow rate per mi-

nute. See maximum "Fluid Delivery Rate"

nute. See maximum "Fluid Delivery Rate"

nute. See maximum "Fluid Delivery Rate"

nute. See maximum "Fluid Delivery Rate"

under "Specifications" in the "Introduction"

under "Specifications" in the "Introduction"

under "Specifications" in the "Introduction"

under "Specifications" in the "Introduction"

section of this manual.

section of this manual.

section of this manual.

section of this manual.

8. Adjust the air pressure to the air motor to

8. Adjust the air pressure to the air motor to

8. Adjust the air pressure to the air motor to

8. Adjust the air pressure to the air motor to

achieve the desired atomization.

achieve the desired atomization.

achieve the desired atomization.

achieve the desired atomization.

9. When complete, move the slide valve switch

9. When complete, move the slide valve switch

9. When complete, move the slide valve switch

9. When complete, move the slide valve switch

to the off position. (Reference Figure 12)

to the off position. (Reference Figure 12)

to the off position. (Reference Figure 12)

to the off position. (Reference Figure 12)

10. Turn the power switch to the “Off” position

10. Turn the power switch to the “Off” position

10. Turn the power switch to the “Off” position

10. Turn the power switch to the “Off” position

on the power supply.

on the power supply.

on the power supply.

on the power supply.

OPERATION

OPERATION

OPERATION

OPERATION