Operation, Procedures – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 21

21

21

21

21

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

OPERATION

OPERATION

OPERATION

OPERATION

PROCEDURES

PROCEDURES

PROCEDURES

PROCEDURES

Prior to operating the No. 2 Handgun, ensure

Prior to operating the No. 2 Handgun, ensure

Prior to operating the No. 2 Handgun, ensure

Prior to operating the No. 2 Handgun, ensure

that the equipment is installed properly (see

that the equipment is installed properly (see

that the equipment is installed properly (see

that the equipment is installed properly (see

"Installation" section of this service manual).

"Installation" section of this service manual).

"Installation" section of this service manual).

"Installation" section of this service manual).

Observe and follow the safety requirements at

Observe and follow the safety requirements at

Observe and follow the safety requirements at

Observe and follow the safety requirements at

ALL times.

ALL times.

ALL times.

ALL times.

1. Inspect the rotating bell assembly to ensure

1. Inspect the rotating bell assembly to ensure

1. Inspect the rotating bell assembly to ensure

1. Inspect the rotating bell assembly to ensure

that it is clean and is not chipped. Replace or

that it is clean and is not chipped. Replace or

that it is clean and is not chipped. Replace or

that it is clean and is not chipped. Replace or

clean the bell assembly when necessary.

clean the bell assembly when necessary.

clean the bell assembly when necessary.

clean the bell assembly when necessary.

2. Set the paint fluid pressure at 0.2 to 0.3 bar

2. Set the paint fluid pressure at 0.2 to 0.3 bar

2. Set the paint fluid pressure at 0.2 to 0.3 bar

2. Set the paint fluid pressure at 0.2 to 0.3 bar

(3 to 4 psi ). Adjust the pressure up or down for

(3 to 4 psi ). Adjust the pressure up or down for

(3 to 4 psi ). Adjust the pressure up or down for

(3 to 4 psi ). Adjust the pressure up or down for

the desired fluid delivery. Higher fluid pressure

the desired fluid delivery. Higher fluid pressure

the desired fluid delivery. Higher fluid pressure

the desired fluid delivery. Higher fluid pressure

may be needed with higher viscosity material,

may be needed with higher viscosity material,

may be needed with higher viscosity material,

may be needed with higher viscosity material,

longer hoses, or higher fluid deliveries.

longer hoses, or higher fluid deliveries.

longer hoses, or higher fluid deliveries.

longer hoses, or higher fluid deliveries.

3. Set the slide valve switch on the applicator to

3. Set the slide valve switch on the applicator to

3. Set the slide valve switch on the applicator to

3. Set the slide valve switch on the applicator to

the “OFF” position as shown in Figure 12. The

the “OFF” position as shown in Figure 12. The

the “OFF” position as shown in Figure 12. The

the “OFF” position as shown in Figure 12. The

Slide Valve will be pulled back against the inlet

Slide Valve will be pulled back against the inlet

Slide Valve will be pulled back against the inlet

Slide Valve will be pulled back against the inlet

air fitting.

air fitting.

air fitting.

air fitting.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

Slide Valve

Slide Valve

Slide Valve

Slide Valve----”OFF” Position

”OFF” Position

”OFF” Position

”OFF” Position

2

2

2

2

Air Inlet Fitting

Air Inlet Fitting

Air Inlet Fitting

Air Inlet Fitting

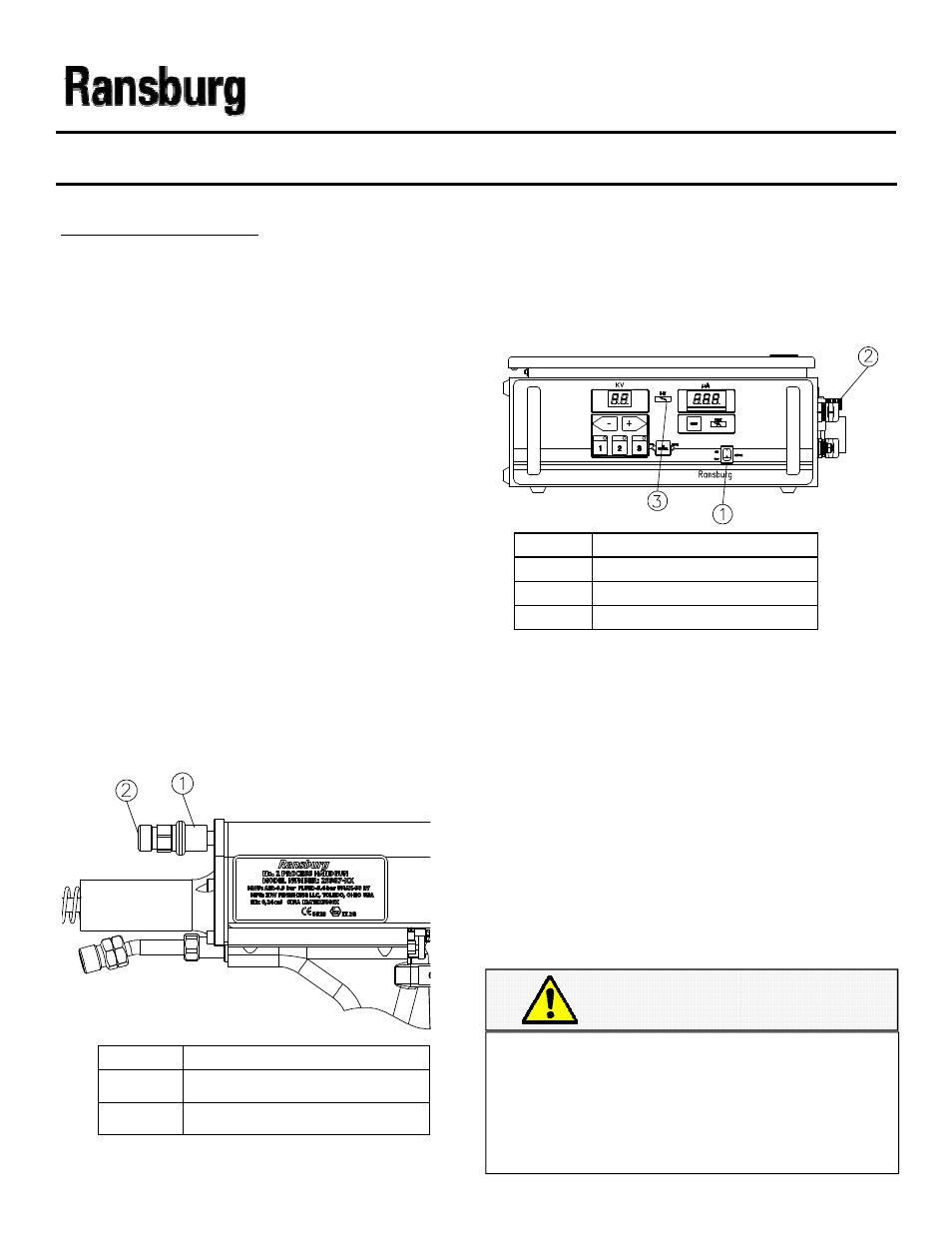

Figure 12: Slide Valve “Off” Position

Figure 12: Slide Valve “Off” Position

Figure 12: Slide Valve “Off” Position

Figure 12: Slide Valve “Off” Position

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

Power ‘ON

Power ‘ON

Power ‘ON

Power ‘ON ---- OFF” Switch

OFF” Switch

OFF” Switch

OFF” Switch

2

2

2

2

Flow Switch Fitting

Flow Switch Fitting

Flow Switch Fitting

Flow Switch Fitting

3

3

3

3

HV on Indicator

HV on Indicator

HV on Indicator

HV on Indicator

Figure 13: 9060 Power “ON

Figure 13: 9060 Power “ON

Figure 13: 9060 Power “ON

Figure 13: 9060 Power “ON----OFF” Switch

OFF” Switch

OFF” Switch

OFF” Switch

5. Push the slide valve switch on the applicator

5. Push the slide valve switch on the applicator

5. Push the slide valve switch on the applicator

5. Push the slide valve switch on the applicator

forward toward the applicator barrel. The air motor

forward toward the applicator barrel. The air motor

forward toward the applicator barrel. The air motor

forward toward the applicator barrel. The air motor

will begin turning and voltage will be present at the

will begin turning and voltage will be present at the

will begin turning and voltage will be present at the

will begin turning and voltage will be present at the

bell. The HV On indicator on the 9060 will illumi-

bell. The HV On indicator on the 9060 will illumi-

bell. The HV On indicator on the 9060 will illumi-

bell. The HV On indicator on the 9060 will illumi-

nate when voltage is on. Figure 14 shows the

nate when voltage is on. Figure 14 shows the

nate when voltage is on. Figure 14 shows the

nate when voltage is on. Figure 14 shows the

speed versus inlet air pressure with the applicator

speed versus inlet air pressure with the applicator

speed versus inlet air pressure with the applicator

speed versus inlet air pressure with the applicator

triggered. This chart may be used to assist with

triggered. This chart may be used to assist with

triggered. This chart may be used to assist with

triggered. This chart may be used to assist with

initial pressure settings .

initial pressure settings .

initial pressure settings .

initial pressure settings .

6.

6.

6.

6. Hold the No. 2 handgun perpendicular to, and

Hold the No. 2 handgun perpendicular to, and

Hold the No. 2 handgun perpendicular to, and

Hold the No. 2 handgun perpendicular to, and

13 to 18 cm (4 to 7 inches ) from the part being

13 to 18 cm (4 to 7 inches ) from the part being

13 to 18 cm (4 to 7 inches ) from the part being

13 to 18 cm (4 to 7 inches ) from the part being

coated. Trigger the handgun and observe the at-

coated. Trigger the handgun and observe the at-

coated. Trigger the handgun and observe the at-

coated. Trigger the handgun and observe the at-

omization of the coating

omization of the coating

omization of the coating

omization of the coating

material.

material.

material.

material.

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

The application process works best when the

The application process works best when the

The application process works best when the

The application process works best when the

bell is positioned perpendicular to the ground-

bell is positioned perpendicular to the ground-

bell is positioned perpendicular to the ground-

bell is positioned perpendicular to the ground-

ed target. Following this method avoids paint

ed target. Following this method avoids paint

ed target. Following this method avoids paint

ed target. Following this method avoids paint

wrapback onto the operator or nearby ob-

wrapback onto the operator or nearby ob-

wrapback onto the operator or nearby ob-

wrapback onto the operator or nearby ob-

jects.

jects.

jects.

jects.

4. Turn the 9060 power “ON

4. Turn the 9060 power “ON

4. Turn the 9060 power “ON

4. Turn the 9060 power “ON----OFF” switch on

OFF” switch on

OFF” switch on

OFF” switch on

the front panel to the “ON” position as shown

the front panel to the “ON” position as shown

the front panel to the “ON” position as shown

the front panel to the “ON” position as shown

in Figure 13. The unit will power up, but high

in Figure 13. The unit will power up, but high

in Figure 13. The unit will power up, but high

in Figure 13. The unit will power up, but high

voltage will not be on at this point. because

voltage will not be on at this point. because

voltage will not be on at this point. because

voltage will not be on at this point. because

the voltage is interlocked with the air flow to

the voltage is interlocked with the air flow to

the voltage is interlocked with the air flow to

the voltage is interlocked with the air flow to

the air motor through the air flow switch locat-

the air motor through the air flow switch locat-

the air motor through the air flow switch locat-

the air motor through the air flow switch locat-

ed in the power supply.

ed in the power supply.

ed in the power supply.

ed in the power supply.