Air/fluid fitting installation pro, Air hose, Installation feed tube, bell – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 16

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

16

16

16

16

Ransburg supplies standard the 80089

Ransburg supplies standard the 80089

Ransburg supplies standard the 80089

Ransburg supplies standard the 80089----25

25

25

25

(7.6 m, 25 ft.) air hose and 8340

(7.6 m, 25 ft.) air hose and 8340

(7.6 m, 25 ft.) air hose and 8340

(7.6 m, 25 ft.) air hose and 8340----25 (7.6 m,

25 (7.6 m,

25 (7.6 m,

25 (7.6 m,

25 ft.) fluid hose standard with the 80086

25 ft.) fluid hose standard with the 80086

25 ft.) fluid hose standard with the 80086

25 ft.) fluid hose standard with the 80086----

XX unit. Other hose lengths up to 30.5 m

XX unit. Other hose lengths up to 30.5 m

XX unit. Other hose lengths up to 30.5 m

XX unit. Other hose lengths up to 30.5 m

(100 ft.) are also available as optional

(100 ft.) are also available as optional

(100 ft.) are also available as optional

(100 ft.) are also available as optional

lengths.

lengths.

lengths.

lengths.

NOTE

NOTE

NOTE

NOTE

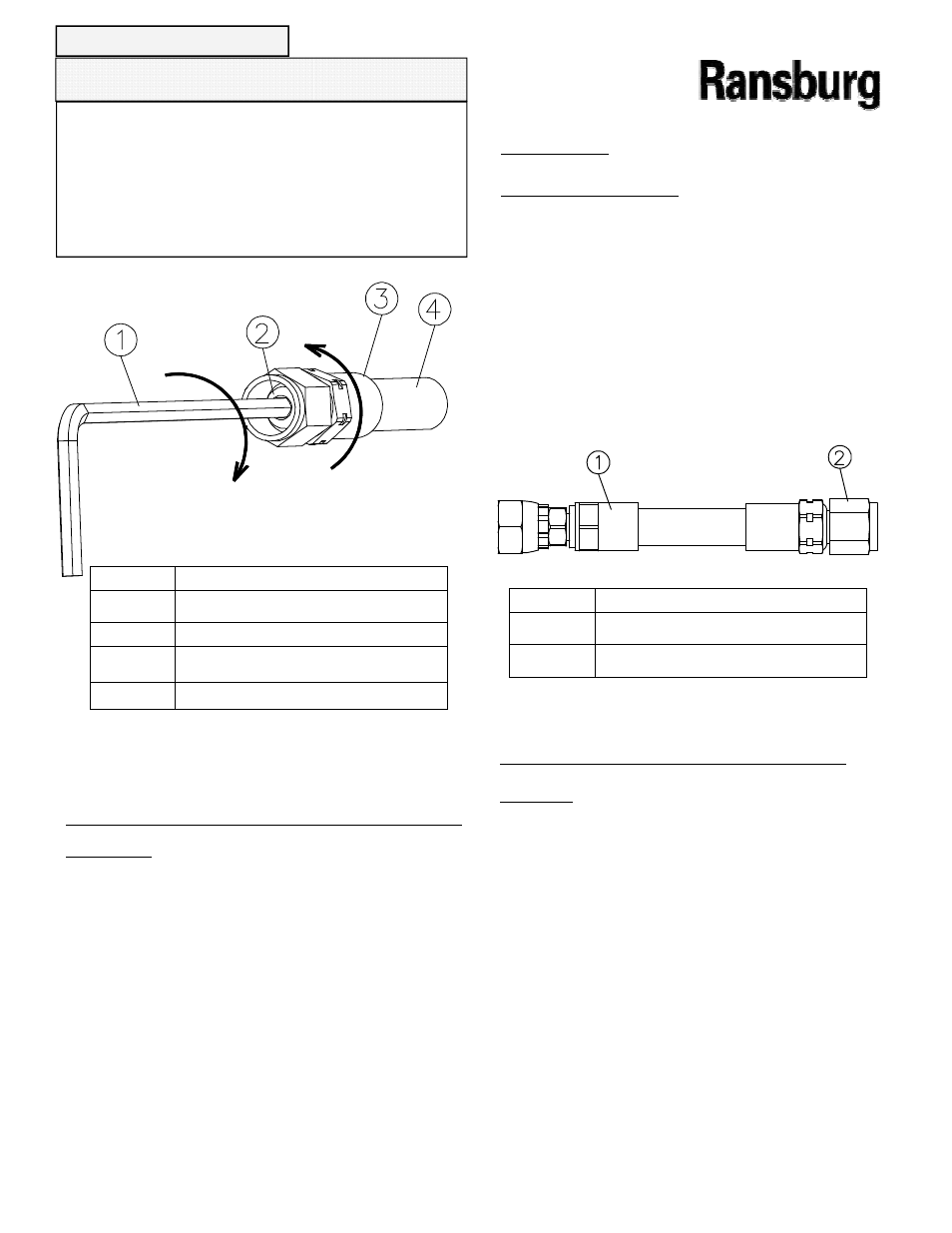

Air/Fluid Fitting Installation Pro-

Air/Fluid Fitting Installation Pro-

Air/Fluid Fitting Installation Pro-

Air/Fluid Fitting Installation Pro-

cedure

cedure

cedure

cedure

1. Lubricate all fittings with dielectric grease.

1. Lubricate all fittings with dielectric grease.

1. Lubricate all fittings with dielectric grease.

1. Lubricate all fittings with dielectric grease.

2. Screw ferrule (item 3) counterclockwise onto

2. Screw ferrule (item 3) counterclockwise onto

2. Screw ferrule (item 3) counterclockwise onto

2. Screw ferrule (item 3) counterclockwise onto

hose (item 4) until it bottoms, then back it off

hose (item 4) until it bottoms, then back it off

hose (item 4) until it bottoms, then back it off

hose (item 4) until it bottoms, then back it off

approximately 3.2 mm (1/8”).

approximately 3.2 mm (1/8”).

approximately 3.2 mm (1/8”).

approximately 3.2 mm (1/8”).

3. Install nut over union stem and start the stem

3. Install nut over union stem and start the stem

3. Install nut over union stem and start the stem

3. Install nut over union stem and start the stem

into the hose.

into the hose.

into the hose.

into the hose.

4. Using a 4.5 mm hex key (3/16

4. Using a 4.5 mm hex key (3/16

4. Using a 4.5 mm hex key (3/16

4. Using a 4.5 mm hex key (3/16----inch ), screw

inch ), screw

inch ), screw

inch ), screw

the union stem into the hose until it bottoms

the union stem into the hose until it bottoms

the union stem into the hose until it bottoms

the union stem into the hose until it bottoms

against the ferrule.

against the ferrule.

against the ferrule.

against the ferrule.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

4.5 mm (3/16”) Hex Key

4.5 mm (3/16”) Hex Key

4.5 mm (3/16”) Hex Key

4.5 mm (3/16”) Hex Key

2

2

2

2

Stem

Stem

Stem

Stem

3

3

3

3

Ferrule

Ferrule

Ferrule

Ferrule

4

4

4

4

Hose (Fluid or Air)

Hose (Fluid or Air)

Hose (Fluid or Air)

Hose (Fluid or Air)

Figure 5: Air or Fluid Fitting Assembly Procedure

Figure 5: Air or Fluid Fitting Assembly Procedure

Figure 5: Air or Fluid Fitting Assembly Procedure

Figure 5: Air or Fluid Fitting Assembly Procedure

Air Hose

Air Hose

Air Hose

Air Hose

(Refer to Figure 6)

(Refer to Figure 6)

(Refer to Figure 6)

(Refer to Figure 6)

1.

1.

1.

1. Connect the 9/16

Connect the 9/16

Connect the 9/16

Connect the 9/16----18 thread to the applica-

18 thread to the applica-

18 thread to the applica-

18 thread to the applica-

tor air inlet.

tor air inlet.

tor air inlet.

tor air inlet.

2.

2.

2.

2. Connect the 3/8 NPS(F) fitting to the “out”

Connect the 3/8 NPS(F) fitting to the “out”

Connect the 3/8 NPS(F) fitting to the “out”

Connect the 3/8 NPS(F) fitting to the “out”

port of the flow switch of the poser supply.

port of the flow switch of the poser supply.

port of the flow switch of the poser supply.

port of the flow switch of the poser supply.

Installation Feed Tube, Bell,

Installation Feed Tube, Bell,

Installation Feed Tube, Bell,

Installation Feed Tube, Bell,

Brush

Brush

Brush

Brush

1. Install the proper feed tube into the opening

1. Install the proper feed tube into the opening

1. Install the proper feed tube into the opening

1. Install the proper feed tube into the opening

in the applicator. See figure 7. Position the

in the applicator. See figure 7. Position the

in the applicator. See figure 7. Position the

in the applicator. See figure 7. Position the

tube at approximately as shown in the figure.

tube at approximately as shown in the figure.

tube at approximately as shown in the figure.

tube at approximately as shown in the figure.

2. Insert the 80084

2. Insert the 80084

2. Insert the 80084

2. Insert the 80084----00 brush into the barrel.

00 brush into the barrel.

00 brush into the barrel.

00 brush into the barrel.

Position it as shown in figure 7.

Position it as shown in figure 7.

Position it as shown in figure 7.

Position it as shown in figure 7.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

3/8 NPS(F)

3/8 NPS(F)

3/8 NPS(F)

3/8 NPS(F) ----To Flow Switch

To Flow Switch

To Flow Switch

To Flow Switch

2

2

2

2

9/16

9/16

9/16

9/16----18 to Applicator

18 to Applicator

18 to Applicator

18 to Applicator

Figure 6: Air Fitting Assembly Procedure

Figure 6: Air Fitting Assembly Procedure

Figure 6: Air Fitting Assembly Procedure

Figure 6: Air Fitting Assembly Procedure

INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION