Needle assembly replacement – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 38

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

38

38

38

38

5. Reverse the handle assembly so that the

5. Reverse the handle assembly so that the

5. Reverse the handle assembly so that the

5. Reverse the handle assembly so that the

side marked “X” is up (Reference Figure 21).

side marked “X” is up (Reference Figure 21).

side marked “X” is up (Reference Figure 21).

side marked “X” is up (Reference Figure 21).

Insert trigger, making sure that the curved lower

Insert trigger, making sure that the curved lower

Insert trigger, making sure that the curved lower

Insert trigger, making sure that the curved lower

tip of the trigger is pointed away from the han-

tip of the trigger is pointed away from the han-

tip of the trigger is pointed away from the han-

tip of the trigger is pointed away from the han-

dle and the thrust washer is to the front of trig-

dle and the thrust washer is to the front of trig-

dle and the thrust washer is to the front of trig-

dle and the thrust washer is to the front of trig-

ger.

ger.

ger.

ger.

6. Insert the roll pin through the hole and into

6. Insert the roll pin through the hole and into

6. Insert the roll pin through the hole and into

6. Insert the roll pin through the hole and into

the trigger pivot hole.

the trigger pivot hole.

the trigger pivot hole.

the trigger pivot hole.

7. With a small hammer, gently drive the roll pin

7. With a small hammer, gently drive the roll pin

7. With a small hammer, gently drive the roll pin

7. With a small hammer, gently drive the roll pin

into the bottom tang, stopping when the roll pin

into the bottom tang, stopping when the roll pin

into the bottom tang, stopping when the roll pin

into the bottom tang, stopping when the roll pin

is about 2.3 mm (3/32”) from the face of the

is about 2.3 mm (3/32”) from the face of the

is about 2.3 mm (3/32”) from the face of the

is about 2.3 mm (3/32”) from the face of the

tang.

tang.

tang.

tang.

Needle Assembly Replacement

Needle Assembly Replacement

Needle Assembly Replacement

Needle Assembly Replacement

1. Complete steps 1 through 4 of "Trigger Re-

1. Complete steps 1 through 4 of "Trigger Re-

1. Complete steps 1 through 4 of "Trigger Re-

1. Complete steps 1 through 4 of "Trigger Re-

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

2. Remove the spring retainer with a 1/ 4

2. Remove the spring retainer with a 1/ 4

2. Remove the spring retainer with a 1/ 4

2. Remove the spring retainer with a 1/ 4----inch

inch

inch

inch

open end wrench and slide the needle assem-

open end wrench and slide the needle assem-

open end wrench and slide the needle assem-

open end wrench and slide the needle assem-

bly out of the handle. It is not necessary to re-

bly out of the handle. It is not necessary to re-

bly out of the handle. It is not necessary to re-

bly out of the handle. It is not necessary to re-

move the two lock nuts and the thrust washer .

move the two lock nuts and the thrust washer .

move the two lock nuts and the thrust washer .

move the two lock nuts and the thrust washer .

3. If the needle packing is to be replaced, refer

3. If the needle packing is to be replaced, refer

3. If the needle packing is to be replaced, refer

3. If the needle packing is to be replaced, refer

to "Needle Packing Replacement" in the

to "Needle Packing Replacement" in the

to "Needle Packing Replacement" in the

to "Needle Packing Replacement" in the

"Maintenance" section.

"Maintenance" section.

"Maintenance" section.

"Maintenance" section.

4. Insert new or rebuilt needle assembly into

4. Insert new or rebuilt needle assembly into

4. Insert new or rebuilt needle assembly into

4. Insert new or rebuilt needle assembly into

the handle and with the 1/4

the handle and with the 1/4

the handle and with the 1/4

the handle and with the 1/4----inch open end

inch open end

inch open end

inch open end

wrench turn the spring retainer in about four

wrench turn the spring retainer in about four

wrench turn the spring retainer in about four

wrench turn the spring retainer in about four

turns.

turns.

turns.

turns.

5. Reinstall all removed parts per instructions in

5. Reinstall all removed parts per instructions in

5. Reinstall all removed parts per instructions in

5. Reinstall all removed parts per instructions in

the “Maintenance Section”.

the “Maintenance Section”.

the “Maintenance Section”.

the “Maintenance Section”.

Needle Assembly Rebuild

Needle Assembly Rebuild

Needle Assembly Rebuild

Needle Assembly Rebuild

1. Complete steps 1 through 3 of "Needle As-

1. Complete steps 1 through 3 of "Needle As-

1. Complete steps 1 through 3 of "Needle As-

1. Complete steps 1 through 3 of "Needle As-

sembly Replacement" in the "Maintenance"

sembly Replacement" in the "Maintenance"

sembly Replacement" in the "Maintenance"

sembly Replacement" in the "Maintenance"

section.

section.

section.

section.

2. Remove lock nuts and thrust washer.

2. Remove lock nuts and thrust washer.

2. Remove lock nuts and thrust washer.

2. Remove lock nuts and thrust washer.

3. Unscrew spring retainer from spring housing

3. Unscrew spring retainer from spring housing

3. Unscrew spring retainer from spring housing

3. Unscrew spring retainer from spring housing

with a 1/4

with a 1/4

with a 1/4

with a 1/4----inch open end wrench. Remove the

inch open end wrench. Remove the

inch open end wrench. Remove the

inch open end wrench. Remove the

spring retainer from the spring housing.

spring retainer from the spring housing.

spring retainer from the spring housing.

spring retainer from the spring housing.

4. Remove the spring, eyelet, and needle from

4. Remove the spring, eyelet, and needle from

4. Remove the spring, eyelet, and needle from

4. Remove the spring, eyelet, and needle from

the spring housing.

the spring housing.

the spring housing.

the spring housing.

5. Wash all parts in solvent and inspect all com-

5. Wash all parts in solvent and inspect all com-

5. Wash all parts in solvent and inspect all com-

5. Wash all parts in solvent and inspect all com-

ponents for damage and wear. Examine the

ponents for damage and wear. Examine the

ponents for damage and wear. Examine the

ponents for damage and wear. Examine the

needle carefully and replace if worn, pitting,

needle carefully and replace if worn, pitting,

needle carefully and replace if worn, pitting,

needle carefully and replace if worn, pitting,

bent, or broken. Replace any questionable

bent, or broken. Replace any questionable

bent, or broken. Replace any questionable

bent, or broken. Replace any questionable

parts.

parts.

parts.

parts.

6. Install snap ring onto needle. Slide eyelet,

6. Install snap ring onto needle. Slide eyelet,

6. Install snap ring onto needle. Slide eyelet,

6. Install snap ring onto needle. Slide eyelet,

large diameter first, onto threaded end of

large diameter first, onto threaded end of

large diameter first, onto threaded end of

large diameter first, onto threaded end of

needle. Install spring over threaded end of

needle. Install spring over threaded end of

needle. Install spring over threaded end of

needle. Install spring over threaded end of

needle and down over small diameter of eye-

needle and down over small diameter of eye-

needle and down over small diameter of eye-

needle and down over small diameter of eye-

let.

let.

let.

let.

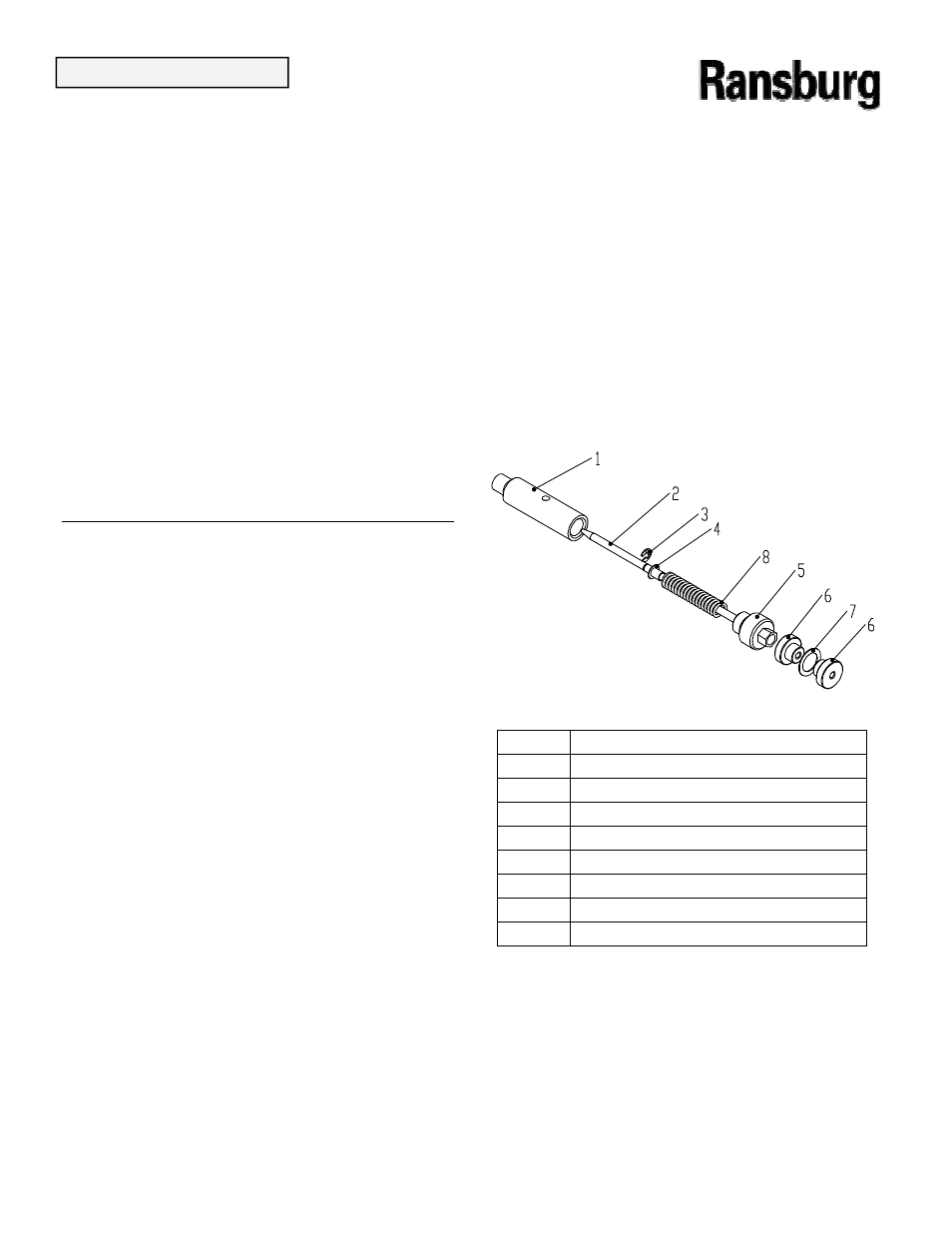

Figure 22: Needle Assembly Diagram

Figure 22: Needle Assembly Diagram

Figure 22: Needle Assembly Diagram

Figure 22: Needle Assembly Diagram

ITEM

ITEM

ITEM

ITEM

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

1

1

1

1

HOUSING, SPRING

HOUSING, SPRING

HOUSING, SPRING

HOUSING, SPRING

2

2

2

2

NEEDLE, No.2 HAND GUN

NEEDLE, No.2 HAND GUN

NEEDLE, No.2 HAND GUN

NEEDLE, No.2 HAND GUN

3

3

3

3

EXTERNAL RETAINING RING

EXTERNAL RETAINING RING

EXTERNAL RETAINING RING

EXTERNAL RETAINING RING

4

4

4

4

EYELET, #5

EYELET, #5

EYELET, #5

EYELET, #5

5

5

5

5

RETAINER, SPRING

RETAINER, SPRING

RETAINER, SPRING

RETAINER, SPRING

6

6

6

6

NUT,LOCK

NUT,LOCK

NUT,LOCK

NUT,LOCK

7

7

7

7

WASHER, PLASTIC THRUST

WASHER, PLASTIC THRUST

WASHER, PLASTIC THRUST

WASHER, PLASTIC THRUST

8

8

8

8

SPRING,COMPRESSION

SPRING,COMPRESSION

SPRING,COMPRESSION

SPRING,COMPRESSION

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE