Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 17

17

17

17

17

AH

AH

AH

AH----12

12

12

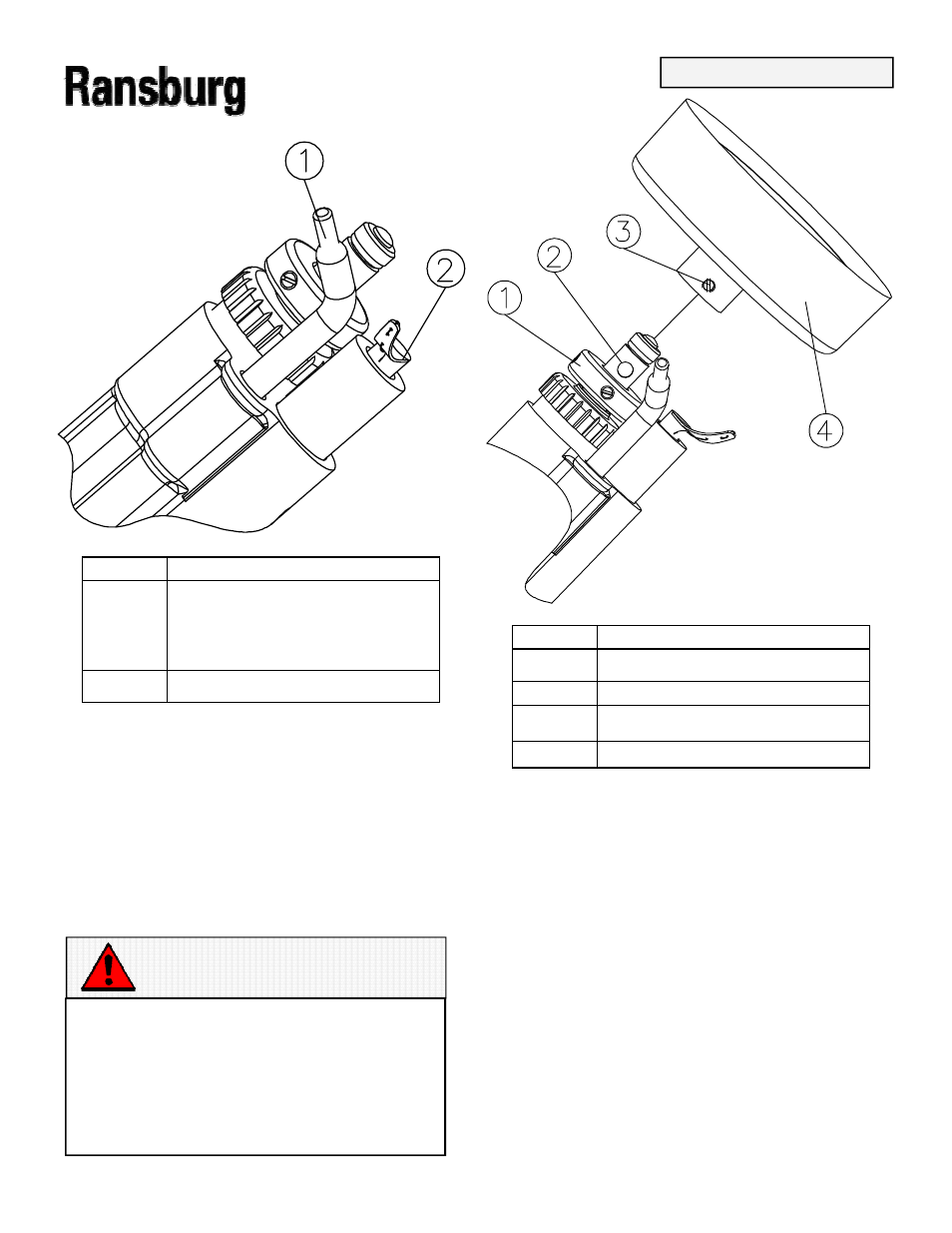

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

Feed Tube 3700

Feed Tube 3700

Feed Tube 3700

Feed Tube 3700----00 for 4” Bell

00 for 4” Bell

00 for 4” Bell

00 for 4” Bell

Feed Tube 6335

Feed Tube 6335

Feed Tube 6335

Feed Tube 6335----00 for 2 3/4”

00 for 2 3/4”

00 for 2 3/4”

00 for 2 3/4”

Bell

Bell

Bell

Bell

2

2

2

2

80085

80085

80085

80085----00 Brush

00 Brush

00 Brush

00 Brush

Figure 7: Initial Position of Feed Tube and Brush

Figure 7: Initial Position of Feed Tube and Brush

Figure 7: Initial Position of Feed Tube and Brush

Figure 7: Initial Position of Feed Tube and Brush

3.

3.

3.

3. Install the bell over the shaft. Hold the shaft

Install the bell over the shaft. Hold the shaft

Install the bell over the shaft. Hold the shaft

Install the bell over the shaft. Hold the shaft

of the applicator and rotate the bell onto the

of the applicator and rotate the bell onto the

of the applicator and rotate the bell onto the

of the applicator and rotate the bell onto the

shaft until the bell is completely seated. Align

shaft until the bell is completely seated. Align

shaft until the bell is completely seated. Align

shaft until the bell is completely seated. Align

the set screw and the flat on the shaft. Tighten

the set screw and the flat on the shaft. Tighten

the set screw and the flat on the shaft. Tighten

the set screw and the flat on the shaft. Tighten

the set screw at the bell hub hand tight. (Refer

the set screw at the bell hub hand tight. (Refer

the set screw at the bell hub hand tight. (Refer

the set screw at the bell hub hand tight. (Refer

to Figure 8)

to Figure 8)

to Figure 8)

to Figure 8)

W A R N I N G

W A R N I N G

W A R N I N G

W A R N I N G

Replacing the plastic set screw with one

Replacing the plastic set screw with one

Replacing the plastic set screw with one

Replacing the plastic set screw with one of

of

of

of

conductive material (metal) will cause a

conductive material (metal) will cause a

conductive material (metal) will cause a

conductive material (metal) will cause a

hazardous condition to exist, capable of

hazardous condition to exist, capable of

hazardous condition to exist, capable of

hazardous condition to exist, capable of

producing an electrical discharge possible

producing an electrical discharge possible

producing an electrical discharge possible

producing an electrical discharge possible

of sparking a fire. In all cases use the plas-

of sparking a fire. In all cases use the plas-

of sparking a fire. In all cases use the plas-

of sparking a fire. In all cases use the plas-

tic screw provided or provided as a spare

tic screw provided or provided as a spare

tic screw provided or provided as a spare

tic screw provided or provided as a spare

part.

part.

part.

part.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

No. 2 Motor Shaft

No. 2 Motor Shaft

No. 2 Motor Shaft

No. 2 Motor Shaft

2

2

2

2

Shaft Locating Flat

Shaft Locating Flat

Shaft Locating Flat

Shaft Locating Flat

3

3

3

3

Bell Set Screw

Bell Set Screw

Bell Set Screw

Bell Set Screw

4

4

4

4

Bell

Bell

Bell

Bell

Figure 8: Installing Bell on Shaft

Figure 8: Installing Bell on Shaft

Figure 8: Installing Bell on Shaft

Figure 8: Installing Bell on Shaft

4.

4.

4.

4. Re

Re

Re

Re----position the feed tube in the bell cavity

position the feed tube in the bell cavity

position the feed tube in the bell cavity

position the feed tube in the bell cavity

at approximately the 4 to 5 o’clock position.

at approximately the 4 to 5 o’clock position.

at approximately the 4 to 5 o’clock position.

at approximately the 4 to 5 o’clock position.

The feed tube should NOT rub on the bell. Ad-

The feed tube should NOT rub on the bell. Ad-

The feed tube should NOT rub on the bell. Ad-

The feed tube should NOT rub on the bell. Ad-

just the feed tube if necessary, by rotating it or

just the feed tube if necessary, by rotating it or

just the feed tube if necessary, by rotating it or

just the feed tube if necessary, by rotating it or

sliding it forward or backward in the barrel.

sliding it forward or backward in the barrel.

sliding it forward or backward in the barrel.

sliding it forward or backward in the barrel.

INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION