Motor assembly replacement, Handle assembly – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 35

35

35

35

35

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

Ensure the power is “OFF” to the 9050 power

Ensure the power is “OFF” to the 9050 power

Ensure the power is “OFF” to the 9050 power

Ensure the power is “OFF” to the 9050 power

supply prior to rotating the bell in step 9.

supply prior to rotating the bell in step 9.

supply prior to rotating the bell in step 9.

supply prior to rotating the bell in step 9.

W A R N I N G

W A R N I N G

W A R N I N G

W A R N I N G

9. Mount the applicator in a padded vise and

9. Mount the applicator in a padded vise and

9. Mount the applicator in a padded vise and

9. Mount the applicator in a padded vise and

turn the motor on by sliding the air inlet slide

turn the motor on by sliding the air inlet slide

turn the motor on by sliding the air inlet slide

turn the motor on by sliding the air inlet slide

valve forward. Listen to the audible pitch of the

valve forward. Listen to the audible pitch of the

valve forward. Listen to the audible pitch of the

valve forward. Listen to the audible pitch of the

motor.

motor.

motor.

motor.

10. Alternately tighten (4) socket head screws

10. Alternately tighten (4) socket head screws

10. Alternately tighten (4) socket head screws

10. Alternately tighten (4) socket head screws

until snug. If motor shaft begins to slow (audible

until snug. If motor shaft begins to slow (audible

until snug. If motor shaft begins to slow (audible

until snug. If motor shaft begins to slow (audible

pitch changes), loosen screws slightly to relieve

pitch changes), loosen screws slightly to relieve

pitch changes), loosen screws slightly to relieve

pitch changes), loosen screws slightly to relieve

binding. DO NOT over tighten screws so that

binding. DO NOT over tighten screws so that

binding. DO NOT over tighten screws so that

binding. DO NOT over tighten screws so that

gasket is squeezed outward beyond the outer

gasket is squeezed outward beyond the outer

gasket is squeezed outward beyond the outer

gasket is squeezed outward beyond the outer

dimension of the barrel.

dimension of the barrel.

dimension of the barrel.

dimension of the barrel.

Over tightening of the (4) socket head

Over tightening of the (4) socket head

Over tightening of the (4) socket head

Over tightening of the (4) socket head

screws can break threaded inserts out of

screws can break threaded inserts out of

screws can break threaded inserts out of

screws can break threaded inserts out of

plastic barrel.

plastic barrel.

plastic barrel.

plastic barrel.

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

Motor Assembly Replacement

Motor Assembly Replacement

Motor Assembly Replacement

Motor Assembly Replacement

1. Follow instructions for removing the cable as-

1. Follow instructions for removing the cable as-

1. Follow instructions for removing the cable as-

1. Follow instructions for removing the cable as-

sembly and motor assembly from the barrel (see

sembly and motor assembly from the barrel (see

sembly and motor assembly from the barrel (see

sembly and motor assembly from the barrel (see

"Cable Assembly Replacement" in the

"Cable Assembly Replacement" in the

"Cable Assembly Replacement" in the

"Cable Assembly Replacement" in the

"Maintenance" section).

"Maintenance" section).

"Maintenance" section).

"Maintenance" section).

2. Replace the motor as required.

2. Replace the motor as required.

2. Replace the motor as required.

2. Replace the motor as required.

3. Follow the assembly instructions for replac-

3. Follow the assembly instructions for replac-

3. Follow the assembly instructions for replac-

3. Follow the assembly instructions for replac-

ing the high voltage cable (see "Cable Assem-

ing the high voltage cable (see "Cable Assem-

ing the high voltage cable (see "Cable Assem-

ing the high voltage cable (see "Cable Assem-

bly Replacement" in the "Maintenance" section).

bly Replacement" in the "Maintenance" section).

bly Replacement" in the "Maintenance" section).

bly Replacement" in the "Maintenance" section).

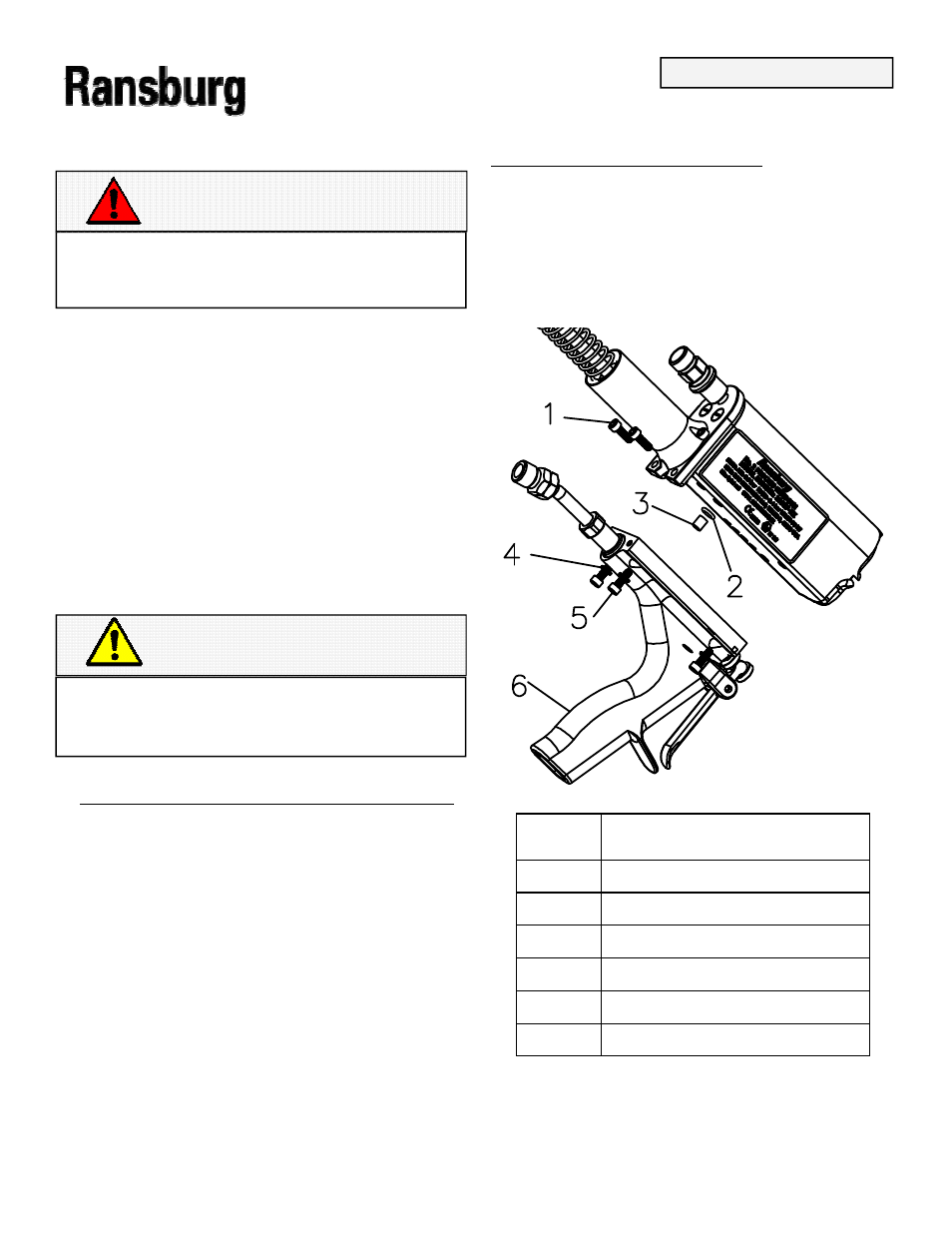

HANDLE ASSEMBLY

HANDLE ASSEMBLY

HANDLE ASSEMBLY

HANDLE ASSEMBLY

1. Invert the applicator and remove the (4)

1. Invert the applicator and remove the (4)

1. Invert the applicator and remove the (4)

1. Invert the applicator and remove the (4)

socket head cap screws and lock washers

socket head cap screws and lock washers

socket head cap screws and lock washers

socket head cap screws and lock washers

from the underside of the handle assembly with

from the underside of the handle assembly with

from the underside of the handle assembly with

from the underside of the handle assembly with

a 9/64

a 9/64

a 9/64

a 9/64----inch hex key wrench. Refer to Figure 20.

inch hex key wrench. Refer to Figure 20.

inch hex key wrench. Refer to Figure 20.

inch hex key wrench. Refer to Figure 20.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

(2) Socket Head Screws

(2) Socket Head Screws

(2) Socket Head Screws

(2) Socket Head Screws

2

2

2

2

O

O

O

O----Ring

Ring

Ring

Ring

3

3

3

3

Bushing, Paint

Bushing, Paint

Bushing, Paint

Bushing, Paint

4

4

4

4

(4) Lock Washers

(4) Lock Washers

(4) Lock Washers

(4) Lock Washers

5

5

5

5

(2) Socket Head Screws

(2) Socket Head Screws

(2) Socket Head Screws

(2) Socket Head Screws

6

6

6

6

Handle Assembly

Handle Assembly

Handle Assembly

Handle Assembly

Figure 20: Handle Assembly Removal

Figure 20: Handle Assembly Removal

Figure 20: Handle Assembly Removal

Figure 20: Handle Assembly Removal

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE