Ceramic seal replacement – Ransburg No. 2 Air Motor Atex Approved Unit 80086-XX User Manual

Page 42

AH

AH

AH

AH----12

12

12

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

42

42

42

42

2. Tilt the Barrel (Item 3) so the rear opening is

2. Tilt the Barrel (Item 3) so the rear opening is

2. Tilt the Barrel (Item 3) so the rear opening is

2. Tilt the Barrel (Item 3) so the rear opening is

down. The resistor (Item 1) and the spring

down. The resistor (Item 1) and the spring

down. The resistor (Item 1) and the spring

down. The resistor (Item 1) and the spring

(Item 2) should fall out of the drive shaft.

(Item 2) should fall out of the drive shaft.

(Item 2) should fall out of the drive shaft.

(Item 2) should fall out of the drive shaft.

3. Measure the resistance of the resistor (Item

3. Measure the resistance of the resistor (Item

3. Measure the resistance of the resistor (Item

3. Measure the resistance of the resistor (Item

2) using a MegOhm meter with leads placed

2) using a MegOhm meter with leads placed

2) using a MegOhm meter with leads placed

2) using a MegOhm meter with leads placed

end to end. The resistance should be between

end to end. The resistance should be between

end to end. The resistance should be between

end to end. The resistance should be between

11,000 to 9,000

11,000 to 9,000

11,000 to 9,000

11,000 to 9,000 M

M

M

MΩ.

Ω.

Ω.

Ω.

If the resistor is outside of

If the resistor is outside of

If the resistor is outside of

If the resistor is outside of

this range, it must be replaced, or there is a

this range, it must be replaced, or there is a

this range, it must be replaced, or there is a

this range, it must be replaced, or there is a

large hole in the center of the spray pattern.

large hole in the center of the spray pattern.

large hole in the center of the spray pattern.

large hole in the center of the spray pattern.

4.

4.

4.

4. Install the ground resistor (Item 2) and spring

Install the ground resistor (Item 2) and spring

Install the ground resistor (Item 2) and spring

Install the ground resistor (Item 2) and spring

(Item 1) back into the drive shaft. Install the ca-

(Item 1) back into the drive shaft. Install the ca-

(Item 1) back into the drive shaft. Install the ca-

(Item 1) back into the drive shaft. Install the ca-

ble/motor assembly per "Cable Assembly Re-

ble/motor assembly per "Cable Assembly Re-

ble/motor assembly per "Cable Assembly Re-

ble/motor assembly per "Cable Assembly Re-

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

placement" in the "Maintenance" section.

Ceramic Seal Replacement

Ceramic Seal Replacement

Ceramic Seal Replacement

Ceramic Seal Replacement

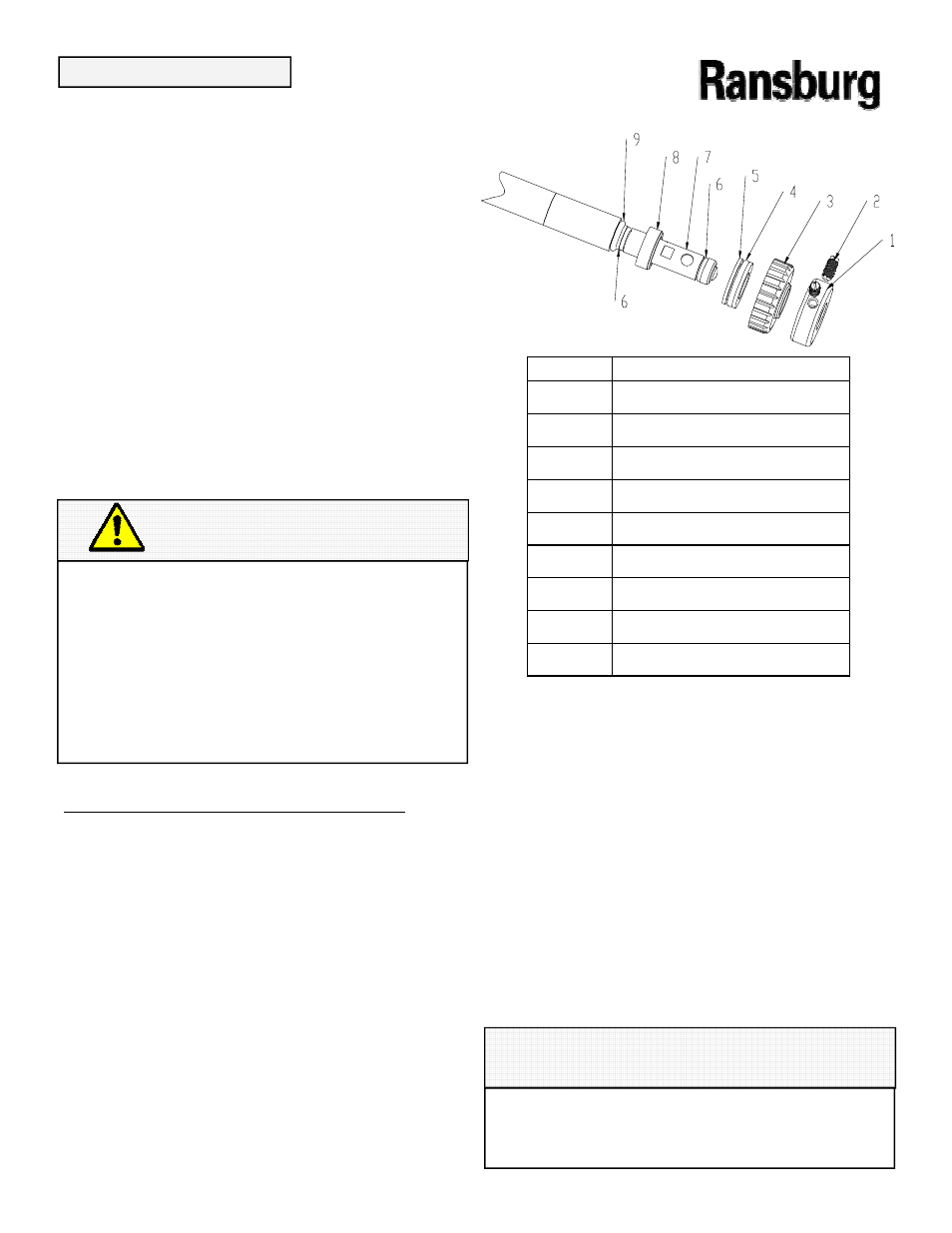

(Refer to Figure 26)

(Refer to Figure 26)

(Refer to Figure 26)

(Refer to Figure 26)

1. Unscrew nut (Item 3) and pull the drive shaft

1. Unscrew nut (Item 3) and pull the drive shaft

1. Unscrew nut (Item 3) and pull the drive shaft

1. Unscrew nut (Item 3) and pull the drive shaft

(Item 7) with all ceramic seal components at-

(Item 7) with all ceramic seal components at-

(Item 7) with all ceramic seal components at-

(Item 7) with all ceramic seal components at-

tached out of the barrel.

tached out of the barrel.

tached out of the barrel.

tached out of the barrel.

2. Remove the O

2. Remove the O

2. Remove the O

2. Remove the O----rings (Item 6) from the drive

rings (Item 6) from the drive

rings (Item 6) from the drive

rings (Item 6) from the drive

shaft, taking care not to damage the drive shaft.

shaft, taking care not to damage the drive shaft.

shaft, taking care not to damage the drive shaft.

shaft, taking care not to damage the drive shaft.

3. Using a screwdriver, loosen the two set

3. Using a screwdriver, loosen the two set

3. Using a screwdriver, loosen the two set

3. Using a screwdriver, loosen the two set

screws (Item 2) (about two turns counterclock-

screws (Item 2) (about two turns counterclock-

screws (Item 2) (about two turns counterclock-

screws (Item 2) (about two turns counterclock-

wise) of the collar (Item 1) and remove the col-

wise) of the collar (Item 1) and remove the col-

wise) of the collar (Item 1) and remove the col-

wise) of the collar (Item 1) and remove the col-

lar and nut (Item 3) from the drive shaft.

lar and nut (Item 3) from the drive shaft.

lar and nut (Item 3) from the drive shaft.

lar and nut (Item 3) from the drive shaft.

4.Slide outer ceramic seal (Item 5) and inner

4.Slide outer ceramic seal (Item 5) and inner

4.Slide outer ceramic seal (Item 5) and inner

4.Slide outer ceramic seal (Item 5) and inner

PTFE seal (Item 6) off the drive shaft .

PTFE seal (Item 6) off the drive shaft .

PTFE seal (Item 6) off the drive shaft .

PTFE seal (Item 6) off the drive shaft .

5. Remove the remaining two O

5. Remove the remaining two O

5. Remove the remaining two O

5. Remove the remaining two O----rings (Items 4

rings (Items 4

rings (Items 4

rings (Items 4

and 9) from the drive shaft .

and 9) from the drive shaft .

and 9) from the drive shaft .

and 9) from the drive shaft .

6. Discard the ceramic seal (Item 5), PTFE

6. Discard the ceramic seal (Item 5), PTFE

6. Discard the ceramic seal (Item 5), PTFE

6. Discard the ceramic seal (Item 5), PTFE

seal (Item 8), O

seal (Item 8), O

seal (Item 8), O

seal (Item 8), O----rings (Items 4,6 and 9). Exam-

rings (Items 4,6 and 9). Exam-

rings (Items 4,6 and 9). Exam-

rings (Items 4,6 and 9). Exam-

ine the drive shaft and replace if damaged.

ine the drive shaft and replace if damaged.

ine the drive shaft and replace if damaged.

ine the drive shaft and replace if damaged.

7. Slide O

7. Slide O

7. Slide O

7. Slide O----ring (Item 10) over drive shaft until it

ring (Item 10) over drive shaft until it

ring (Item 10) over drive shaft until it

ring (Item 10) over drive shaft until it

bottoms on shoulder. Install O

bottoms on shoulder. Install O

bottoms on shoulder. Install O

bottoms on shoulder. Install O----ring (Item 6)

ring (Item 6)

ring (Item 6)

ring (Item 6)

into second O

into second O

into second O

into second O----ring groove of drive shaft.

ring groove of drive shaft.

ring groove of drive shaft.

ring groove of drive shaft.

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

DO NOT Apply Dielectric Grease

DO NOT Apply Dielectric Grease

DO NOT Apply Dielectric Grease

DO NOT Apply Dielectric Grease to the

to the

to the

to the

Resistor (Item 2), Spring (Item 1), or In-

Resistor (Item 2), Spring (Item 1), or In-

Resistor (Item 2), Spring (Item 1), or In-

Resistor (Item 2), Spring (Item 1), or In-

side and Outside Diameters of the Drive

side and Outside Diameters of the Drive

side and Outside Diameters of the Drive

side and Outside Diameters of the Drive

Shaft .

Shaft .

Shaft .

Shaft .

The application of dielectric grease or

The application of dielectric grease or

The application of dielectric grease or

The application of dielectric grease or

any other lubricant to these compo-

any other lubricant to these compo-

any other lubricant to these compo-

any other lubricant to these compo-

nents can cause premature failure of

nents can cause premature failure of

nents can cause premature failure of

nents can cause premature failure of

the motor.

the motor.

the motor.

the motor.

Item #

Item #

Item #

Item # Description

Description

Description

Description

1

1

1

1

Collar

Collar

Collar

Collar

2

2

2

2

Set Screw (2) required

Set Screw (2) required

Set Screw (2) required

Set Screw (2) required

3

3

3

3

Nut

Nut

Nut

Nut

4

4

4

4

O

O

O

O----ring

ring

ring

ring

5

5

5

5

Seal, Outer Ceramic

Seal, Outer Ceramic

Seal, Outer Ceramic

Seal, Outer Ceramic

6

6

6

6

O

O

O

O----ring (2) required

ring (2) required

ring (2) required

ring (2) required

7

7

7

7

Shaft , Drive

Shaft , Drive

Shaft , Drive

Shaft , Drive

8

8

8

8

Seal, Inner, PTFE

Seal, Inner, PTFE

Seal, Inner, PTFE

Seal, Inner, PTFE

9

9

9

9

O

O

O

O----ring

ring

ring

ring

Figure 26: Ceramic Seal Replacement

Figure 26: Ceramic Seal Replacement

Figure 26: Ceramic Seal Replacement

Figure 26: Ceramic Seal Replacement

NOTE

NOTE

NOTE

NOTE

Lightly lubricate the O

Lightly lubricate the O

Lightly lubricate the O

Lightly lubricate the O----rings only with

rings only with

rings only with

rings only with petroleum

petroleum

petroleum

petroleum

jelly. DO NOT USE SILICONE LUBRICANTS!

jelly. DO NOT USE SILICONE LUBRICANTS!

jelly. DO NOT USE SILICONE LUBRICANTS!

jelly. DO NOT USE SILICONE LUBRICANTS!

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE