Summary of quality assurance checks, 8 summary of quality assurance checks -21, Able – Teledyne 6200A - Sulfides analyzer User Manual

Page 128: 14: a, Ctivity, Atrix, 8 summary of quality assurance checks

TAI Model 6200A SO

2

Analyzer Operator Manual, 02164, Rev. G

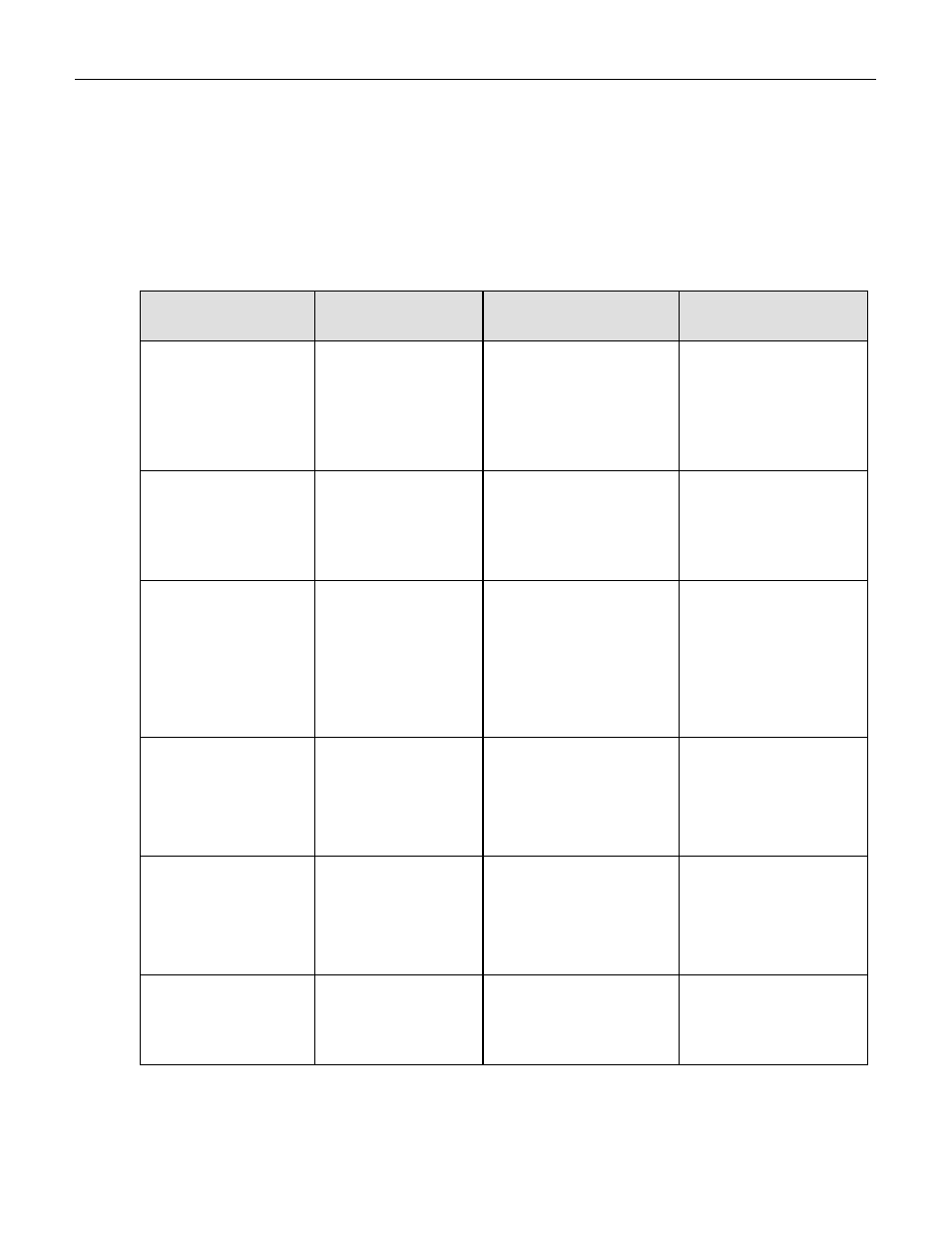

7.8.8 Summary of Quality Assurance Checks

The following items should be checked on a regularly scheduled basis to assure high quality data

from the 6200A. See Table 7-14 for a summary of activities also the QA Handbook should be

checked for specific procedures.

Table 7-14: Activity Matrix

Characteristic

Acceptance limits

Frequency and method

of measurement

Action if requirements

are not met

Shelter temperature

Mean temperature

between 22

o

C and

28

o

C (72

o

and 82

o

F),

daily fluctuations

not greater than

±2

o

C

Check thermograph

chart weekly for

variations greater than

±2

o

C (4

o

F)

1. Mark strip chart for

the affected time

period

2. Repair or adjust

temperature control

Sample introduction

system

No moisture, foreign

material, leaks,

obstructions; sample

line connected to

manifold

Weekly visual inspection Clean, repair, or replace

as needed

Recorder

1. Adequate ink &

paper

2. Legible ink traces

3. Correct chart

speed and range

4. Correct time

Weekly visual inspection 1. Replenish ink and

paper supply

2. Adjust time to agree

with clock; note on

chart

Analyzer operational

settings

1. TEST

measurements at

nominal values

2. 2. 6200A in

SAMPLE mode

Weekly visual inspection Adjust or repair as

needed

Analyzer operational

check

Zero and span within

tolerance limits as

described in Subsec.

9.1.3 of Sec. 2.0.9

(Q.A. Handbook)

Level 1 zero/span every

2 weeks; Level 2

between Level 1 checks

at frequency desired

analyzer by user

1. Find source of error

and repair

2. After corrective

action, re-calibrate

analyzer

Precision check

Assess precision as

described in Sec.

2.0.8 and Subsec.

3.4.3 (Ibid.)

Every 2 weeks, Subsec.

3.4.3 (Ibid.)

Calc, report precision,

Sec. 2.0.8 (Ibid.)

7-21