Epa protocol calibration, Calibration of equipment, 8 epa p – Teledyne 6200A - Sulfides analyzer User Manual

Page 116: Rotocol, Alibration, 1 calibration of equipment -9, Able, 7: izs, Z/s v, Alves

TAI Model 6200A SO

2

Analyzer Operator Manual, 02164, Rev. G

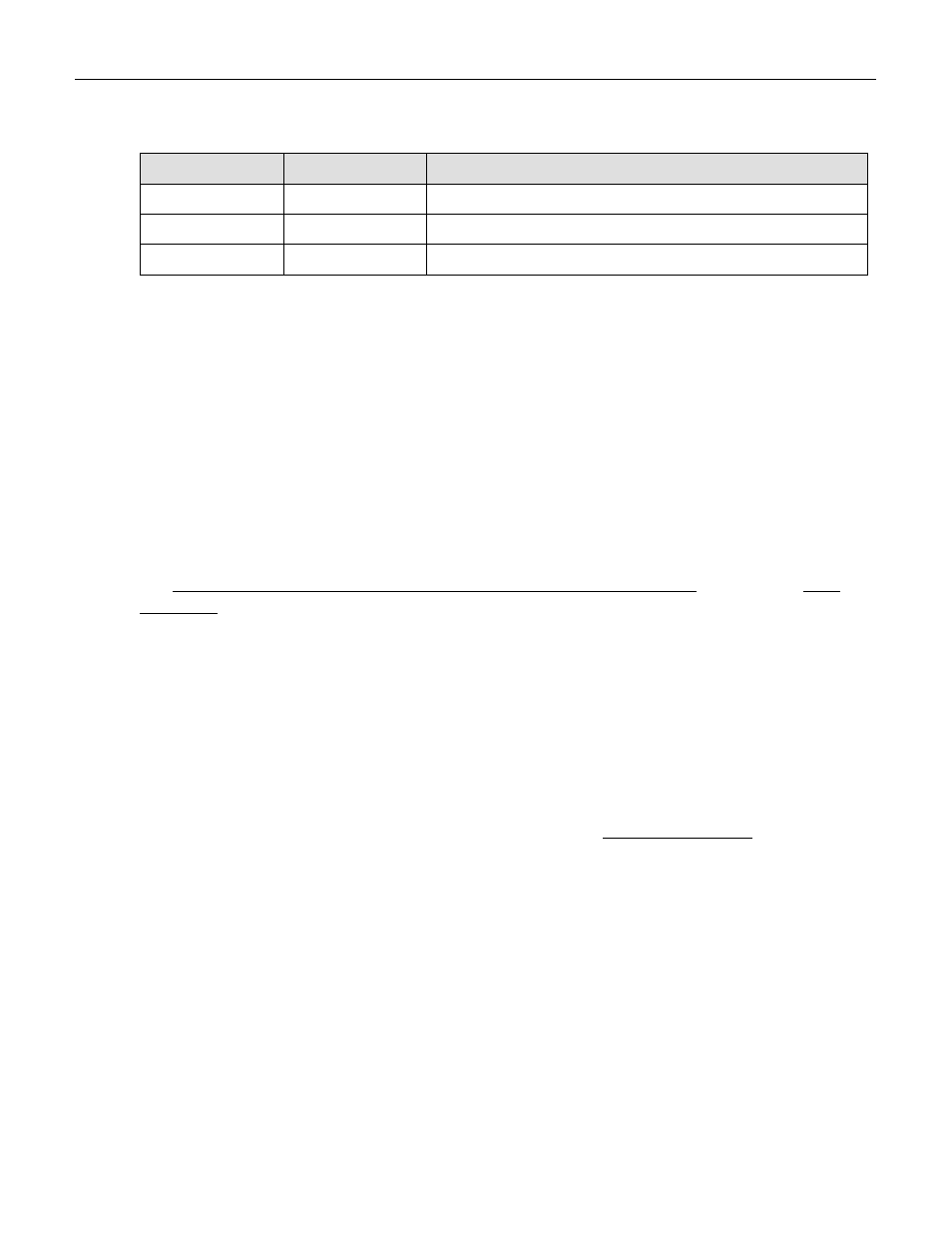

Table 7-7: IZS or Z/S Valves Modes with Remote Contact Closure

Ext Zero CC

Ext Span CC

Operation

Contact Open

Contact Open

State when in SAMPLE mode, normal monitoring.

Contact Open

Contact Closed

Span check or calibrate

*

Contact Closed

Contact Open

Zero check or calibrate

*

* Calibrate only if Dynamic Calibration is enabled (see Table 9-5).

7.8 EPA Protocol Calibration

If the 6200A is to be used for EPA SLAMS monitoring, it must be calibrated in accordance with

the instructions in this section.

In order to insure that high quality, accurate measurements are obtained at all times, the 6200A

must be calibrated prior to use. A quality assurance program centered on this aspect and

including attention to the built-in warning features of the 6200A, periodic inspection, regular

zero/span checks and routine maintenance is paramount to achieving this.

In order to have a better understanding of the factors involved in assuring continuous and

reliable information from the 6200A, it is strongly recommended that Publication No. PB 273-

518 Quality Assurance Handbook for Air Pollution Measurement Systems (abbreviated, Q.A.

Handbook) be purchased from the NTIS (phone 703-605-6000). Special attention should be paid

to Section 2.9 which deals with fluorescence based SO

2

analyzers and upon which most of this

section is based. Specific regulations regarding the use and operation of ambient sulfur dioxide

analyzers can be found in 40 CFR 50 and 40 CFR 58. Both publications are available from the

U.S. Government Printing Office (phone 202-512-0327).

7.8.1 Calibration of Equipment

In general, calibration is the process of adjusting the gain and offset of the 6200A against some

recognized standard. The reliability and usefulness of all data derived from any analyzer depends

primarily upon its state of calibration. In this section the term dynamic calibration is used to

express a multipoint check against known standards and involves introducing gas samples of

known concentration into the instrument in order to adjust the instrument to a predetermined

sensitivity and to produce a calibration relationship. This relationship is derived from the

instrumental response to successive samples of different known concentrations. As a minimum,

three reference points and a zero point are recommended to define this relationship. The true

values of the calibration gas must be traceable to NIST-SRM's.

7-9