Clogs, Fluid leaks, Clogs fluid leaks – Luminex MAGPIX Hardware and Installation Manual User Manual

Page 88

Clogs

Often, a clog somewhere in MAGPIX is the cause of a problem with calibration, verification,

or data acquisition. To determine whether there is a clog, run performance verification to see

if the fluidics function is operating properly. In the event you encounter a problem that is clog-

related, use the following procedure.

To troubleshoot a possible clog:

1. Clean and adjust the sample probe.

on page 60.

2. Perform the procedure for removing clogs.

on page 62.

3. Run calibration and verification.

If this procedure is unsuccessful, call Luminex Technical Support.

Fluid Leaks

There are numerous places in MAGPIX where fluid can leak. Most leaks can be easily fixed;

for the remainder, call Technical Support.

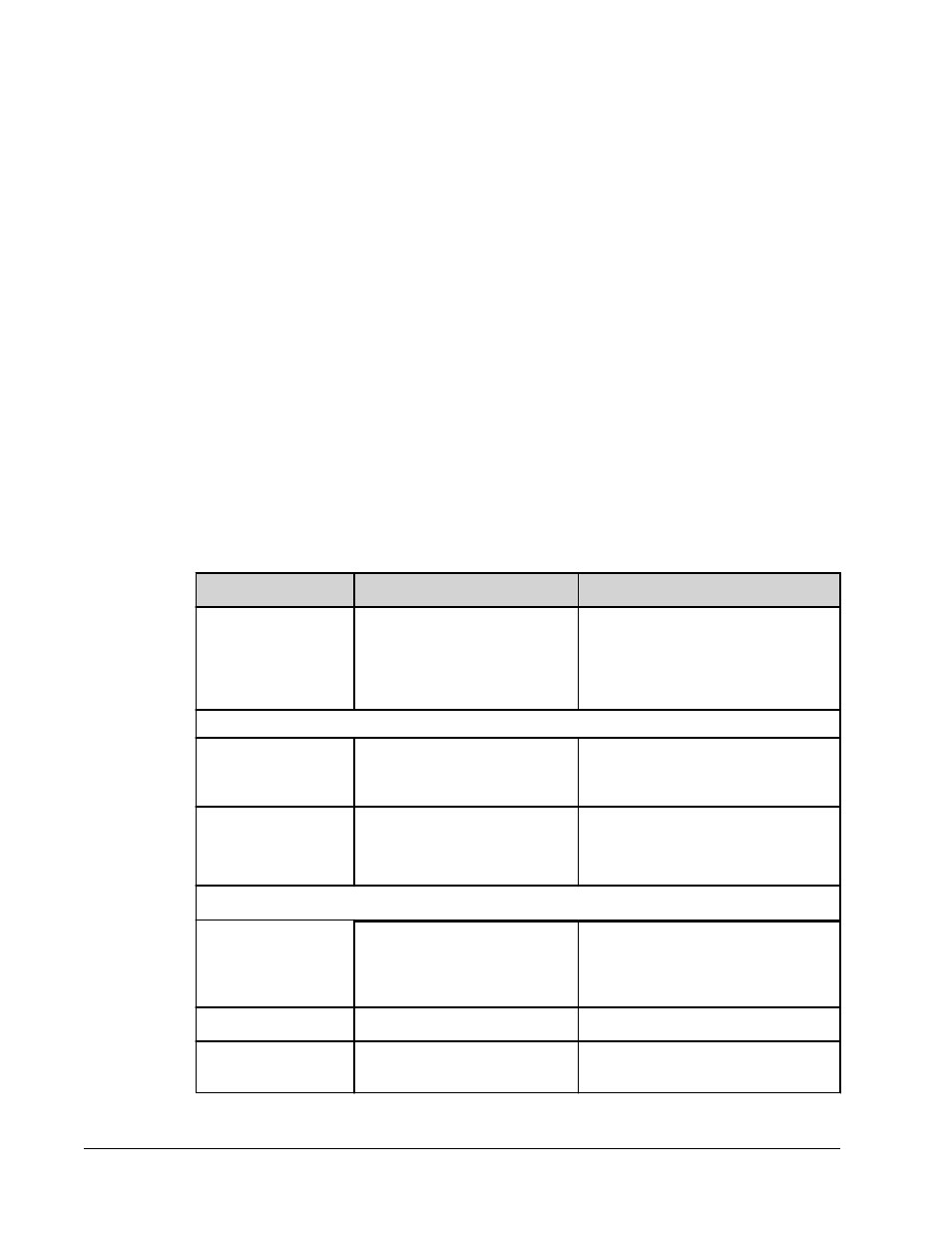

Problem

Possible Cause

Corrective Action

Fluid is pooled around

MAGPIX.

Fittings, fluid tubes, or

components are damaged, loose,

or faulty.

Turn off and disconnect the instrument

to avoid electrical shock. Check for

possible sources of Ieaking and correct

them. If leaking continues, contact

Technical Support.

Sample splashing:

A sample splashes,

giving the appearance

of a fluid leak.

A sample probe is clogged or

partially clogged.

Clean the sample probe.

The plate is warped or improperly

seated, or plate wells are

punctured by the probe.

Replaced warped plates; ensure plate is

properly centered within plate guides on

the plate tray; readjust probe height to

ensure wells are not being punctured.

Fluid leaks within the instrument:

A fluid tube leaks.

The tube is damaged.

If it is the sample probe tube, replace it.

Replacing the Sample Probe Tube

on

page 66. Otherwise, contact Technical

Support.

The waste bottle leaks. The waste bottle fitting is loose.

Reset the waste bottle fitting.

The Drive Fluid filter

leaks.

Drive Fluid filter fittings are loose.

Hand tighten the Drive Fluid filter

fittings.

Troubleshooting Procedures

75