Overview of 2551 display magmeter, Chemical compatibility warning – GF Signet 2551 Magmeter Flow Sensor - Display User Manual

Page 4

4

2551 Magmeter

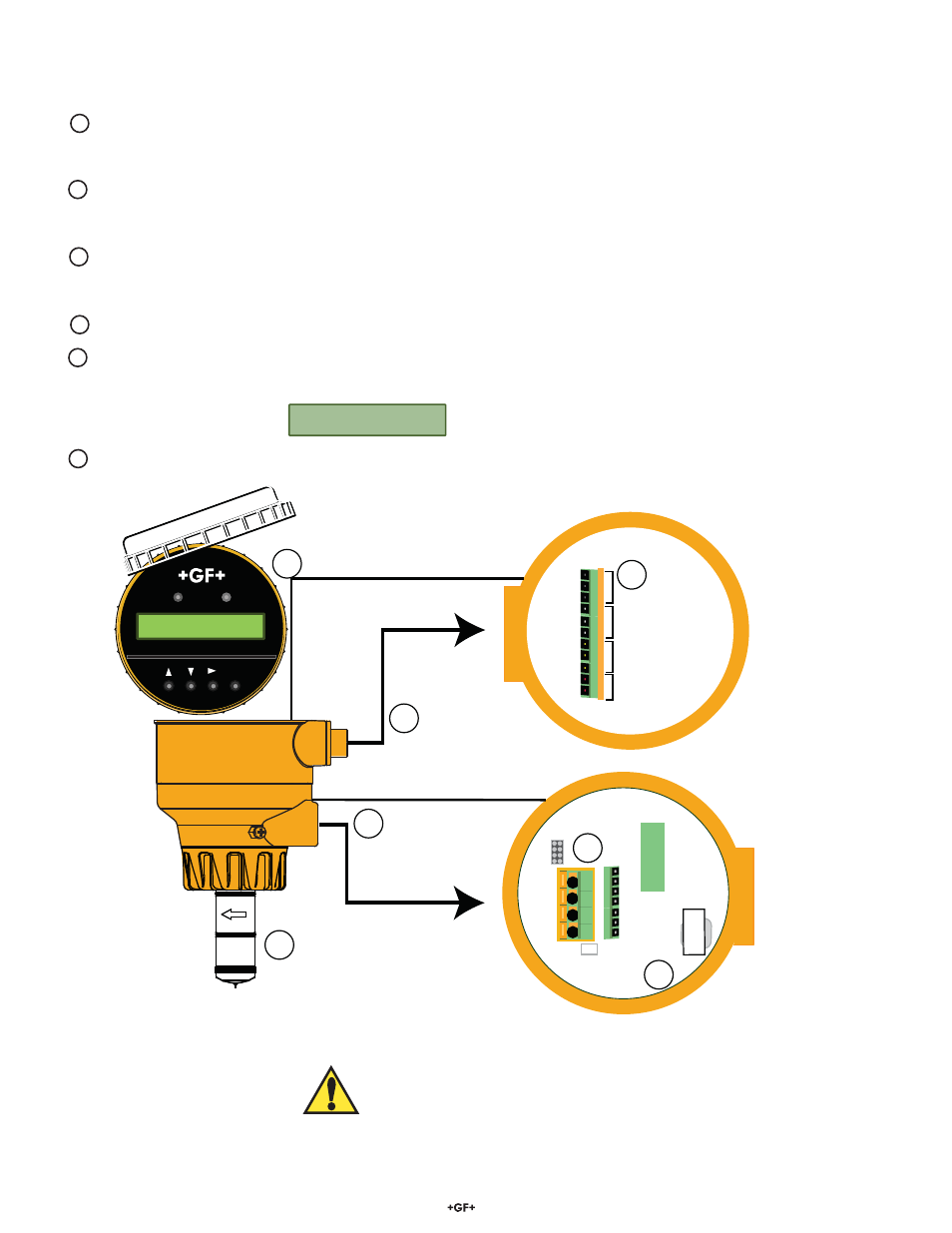

4. Overview of 2551 Display Magmeter

2551 Display Magmeters use a dual-sided electronics module and dual conduit ports. Unused ports must be sealed to protect the

electronics from water damage.

1. The lower set of conduit ports provide access to the wiring terminals for:

• Loop Power

• Flow Output Signal (current loop, Digital (S

3

L), frequency or Mirror Relay 1 output).

2. The upper set of conduit ports provide access to the wiring terminals for:

• Relay output wiring

• Auxiliary power for relay coils and display backlight

3. The sensor is marked with a directional arrow to indicate the direction identi¿ ed as forward À ow.

• An adhesive decal is also provided that can be af¿ xed to the pipe to indicate the direction of forward À ow.

• Flow in the opposite direction from the arrow will be identi¿ ed as reverse À ow on the display by a "-" symbol.

4. The terminals in the magmeter are designed to accomodate 16 to 22 AWG conductors.

5. The display includes two LEDs that light when Relay 1 or Relay 2 are activated.

• All three relays can be monitored by scrolling to the Relay Status display located in the View menu.

• If the Language option has not been made, new magmeters will always open with the Select Language display.

6. The part number, serial number and output type are identi¿ ed on the electronics module.

Language

English >

4 to 20 mA output

Digital (S

3

L) output

Frequency output

Mirror relay 1 output

Relay 1

Relay 2

NO1

NO2

NO3

NC1

NC2

NC3

C1

C2

C3

V+

V-

Relay 3

Aux Pwr

Relay output

Aux power

Signet Magmeter

RELAY 1

RELAY 2

ENTER

420 GPM

123456.78 >

4-20/freq out

s/n 60504201234

60504201234

p/n 3-2551-11

3-2551-11

2.

3.

4.

5.

6.

4.

1

2

3

4

1.

The retaining nuts of Magmeters are not designed for prolonged contact with aggressive substances. Strong acids, caustic substances

and solvents or their vapor may lead to failure of the retaining nut, ejection of the sensor and loss of the process À uid with possibly

serious consequences, such as damage to equipment and serious personal injury. Retaining nuts that may have been in contact with

such substances e.g. due to leakage or spilling, must be replaced.

Chemical Compatibility Warning