Installation – GF Signet 8150 Battery-Powered Flow Totalizer User Manual

Page 2

2

8150 Flow Totalizer

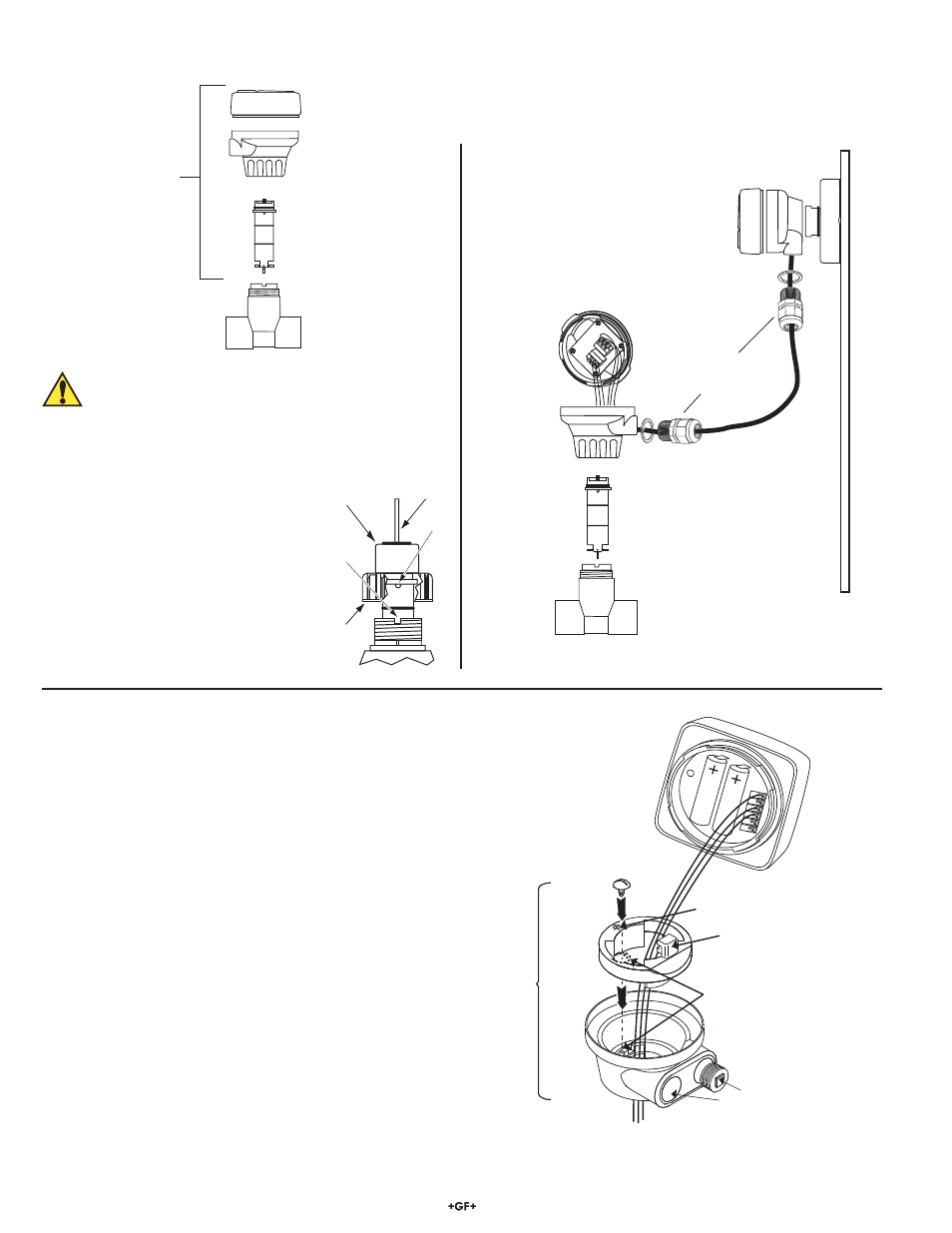

1. Insert the wires from the sensor through the yellow conduit

base and locking ring.

2. Insert the locking ring into the conduit base, aligning it so that

the square tab is close to the conduit ports.

3. Insert the mounting screw into the conduit base so the

head of the screw presses down on the locking ring when

tightened.

4. Connect sensor wires to the terminal connections on the

integral totalizer or terminal cover.

5. Remove the plastic pull tabs protecting the batteries, this will

cause the totalizer unit to power up.

6. For remote assembly, connect output wires to terminal cover

output.

7. Route the output wires through the conduit port in the conduit

base. Use a liquid-tight connector or conduit connector to

prevent moisture from entering the assembly.

8. Place totalizer or cover onto conduit base and twist to

lock in place.

3.4 Conduit Base Assembly Detail

The Mounting Screw for the

Locking Ring goes into the Conduit

Base (not the Locking Ring) -- the

screw head rests on the lip of the

Locking Ring.

Do not use this hole.

Sensor wires

Locking

Ring

Conduit

Base

Conduit

Ports

Mounting

Screw

Conduit

Base Kit

3-8150

Flow Totalizer

Square Tab

3.1 Integral Installation with Field Mount Totalizer

Universal

Conduit Base

(3-8050)

Terminal Cover

(4-3111)

Liquid-tight Connector

(3-9000.392-1)

Flow

Totalizer

(3-8150-1)

Integral

Flow Sensor

(3-8510)

Signet

Fittings

Integral

Mounting Kit

(3-8051-X)

3.2 Remote Field Mount on Wall

3. Installation

The parts identifi ed in bold type are required for this installation.

Other parts are shown for reference only.

Use 2-conductor shielded cable no more than 30 m (100 ft) long.

3-8150-P0

3-8150-P1

3-8150-T0

3-8150-V0

(3-8510-XX)

(3-8051-X)

(3-8150-1)

Flow

Totalizer

Integral

Mounting Kit

Integral

Flow Sensor

Signet

Fittings

Integral Mount

3.3 Plastic Sensor Installation Tips

• Lubricate O-rings with a non-petroleum

based, viscous lubricant (grease)

compatible with the system.

• Using an alternating/twisting motion,

lower the sensor into the fi tting, making

sure the installation arrows on the

black cap are pointing in the direction

of fl ow.

• Engage one thread of the sensor cap

then turn the sensor until the alignment

tab is seated in the fi tting notch.

sensor

bale

sensor

cap

tab

black

conduit

cap

notch

HAND-TIGHTEN THE THREADED NUT ONTO THE

INSTALLATION FITTING. DO NOT USE TOOLS!

DO NOT USE THREAD SEALANT OR LUBRICANTS

ON THE FITTING THREADS OR THE SENSOR CAP.