8 electrical interfacing, Models 5800-s, Installation and operation manual – Brooks Instrument 5800S Series User Manual

Page 12

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Models 5800-S

12

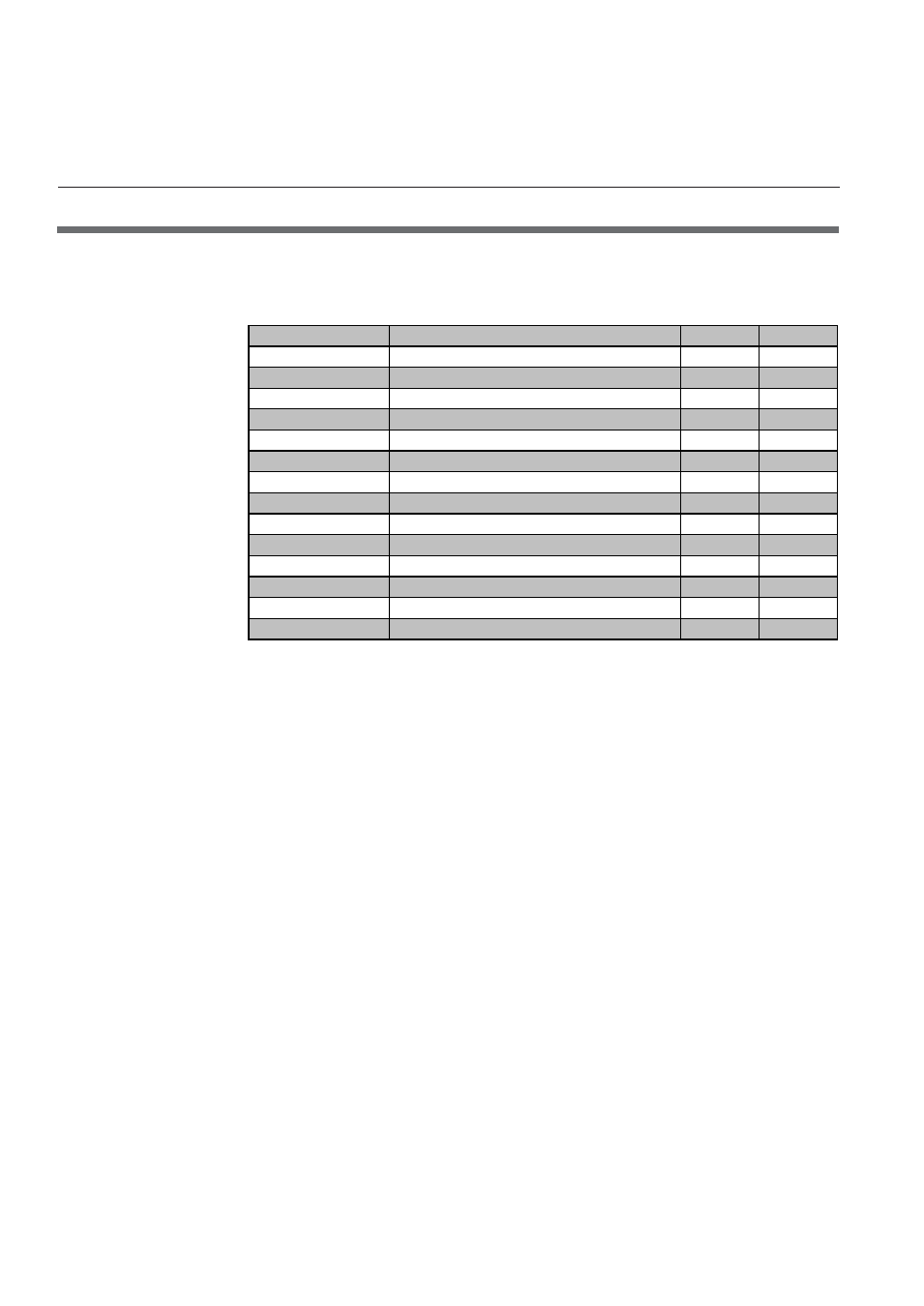

2.8 Electrical Interfacing

The installation of Smart TMF includes a 15-pin Sub-D connector. For details of

correct installation, see Table 2-1

Table 2-1: Electrical interfacing. Smart TMF

Pin (TMF side)

Function

Controller

Meter

1.

Setpoint return (-)

*

n.a.

2.

0 (1)-5 Vdc Flow signal output

*

*

3.

(TTL) Open collector alarm output

*

*

4.

0 (4)-20 mA Flow signal output

*

*

5.

+15 Vdc to +28 Vdc Power supply

*

*

6.

-15 Vdc Power supply (if required)

*

*

7.

0 (4)-20 mA Setpoint input (+)

*

n.a.

8.

0 (1)-5 Vdc Setpoint input (+)

*

n.a.

9.

Power supply common

*

*

10.

Flow signal output common

*

*

11.

+5 Vdc ref. output

*

n.a.

12.

Valve override input

*

n.a.

13.

Not connected

*

*

14.

Optional RS232C-RxD or RS485-A-

*

*

Signal Output (pins 2, 4 and 10)

Pin 2 indicates the flow rate, represented by a 0-5 Vdc or 1-5 Vdc signal

proportional to the mass flow. Pin 4 indicates the flow rate, represented by

either a 0-20 mA or 4-20 mA signal current proportional to the mass flow. Both

the current and voltage signals are returned via pin 10 on the D-connector.

Analogue Setpoint Input (pins 7/8 and 1; Controller models only) . The Smart

Mass Flow Controller can be used either with a current or voltage Set point. To

use the current Set point, connect the Set point signal to pin 7 and the Set

point return signal to pin 1 on the terminal (jumper J1 must be in place refer to

Figure 2-2). To use the voltage Set point, connect the Set point signal to pin 8

and the Set point return to pin 1 on the D-connector.

5 Vdc reference (pin 11; Controller models only)

A +5 Vdc ref. voltage is available on pin 11. This can be used to set the

Setpoint with the aid of an externally located potentiometer (10 turn 2 KOhm

suggested)..

NOTE: I/O configuration to be defined at time of ordering. Reconfiguration at

customer side can be accomplished using digital communication.

Power Supply

Mass Flow Meter models (pin 5 and 9): The Mass Flow Meter's power

supply is connected via pins 5 (+15 to +28 Vdc) and 9 (power supply common)

on the D-connector.

Mass Flow Controller models (pin 5, 6 and 9): The Mass Flow Controller's

power supply is connected via pin 5 (+15 to +28 Vdc) and 9 (power supply

Section 2: Installation