Franklin Fueling Systems TS-DIM User Manual

Page 22

22

Using the Internal Diagnostics to Collect Site Data

Be prepared, some of these steps involve dispensing at least 1/10 of a gallon of each product from all Fueling Points. See

the following section for more details.

A. The FFS Tank Sentinel console must be programmed with the information from the TS-DIM for site configuration and

layout.

B. Make copies of the blank fueling point tables (Figure 21) so that all of the information can be recorded for each fueling

point and meter.

C. See Figure 20 for an example of how to fill out a fueling point table.

D. Enter the Fueling Point No.(s) at the top of each table.

E. Start at Fuel Point #1, each product that can be dispensed at this fueling point is represented by a Meter #. For

example, if a fueling point can dispense Unleaded, Midgrade, and Super, then it will have three meters. Enter a meter

number for each product that can be dispensed at this fueling point. Note that although the table shows eight possible

meter positions per fueling point, usually only three or four will be used (Figure 21).

F. At Fueling Point 2, each product should again be assigned to a meter. The meter number will continue to increase and

should never be duplicated.

G. In the case of blenders, each meter (product) will be dispensed from a primary tank (A) and, maybe, from a secondary

tank (B). Record the tank number(s) for each meter as programmed in the FFS tank gauge. If the meter is a blended

product, then the greatest percentage of the blended product will come from the primary tank and should also be

recorded.

H. When there are two opposing Fueling Points (one dispenser), each will have a meter with the same tank configuration.

These meters should be listed opposite each other in the Fueling Point Table.

I. The internal diagnostics shows eight possible Grades for each Fueling Point. When the product is dispensed from

Meter 1, the total volume that was dispensed will show up in one of the Grade positions under Fueling Point 1. This

Grade number should be assigned to Meter 1.

J. Dispense product from each Meter and/or monitor sales activity to determine the Grade assignments of each Meter.

Note: Grade assignments may be consistent from Fueling Point to Fueling Point, but it is not guaranteed.

Note: Pay particular attention to changes in dispenser type, for instance: one island having a 3 + 1 gasoline and diesel

dispenser. The grade assignments can change drastically in this case. Mistakes in grade assignments can create

problems that will be very difficult to trace.

J. When the data collection is complete, disconnect the straight DB9 serial cable and finish connecting the TS-DIM to the

tank gauge.

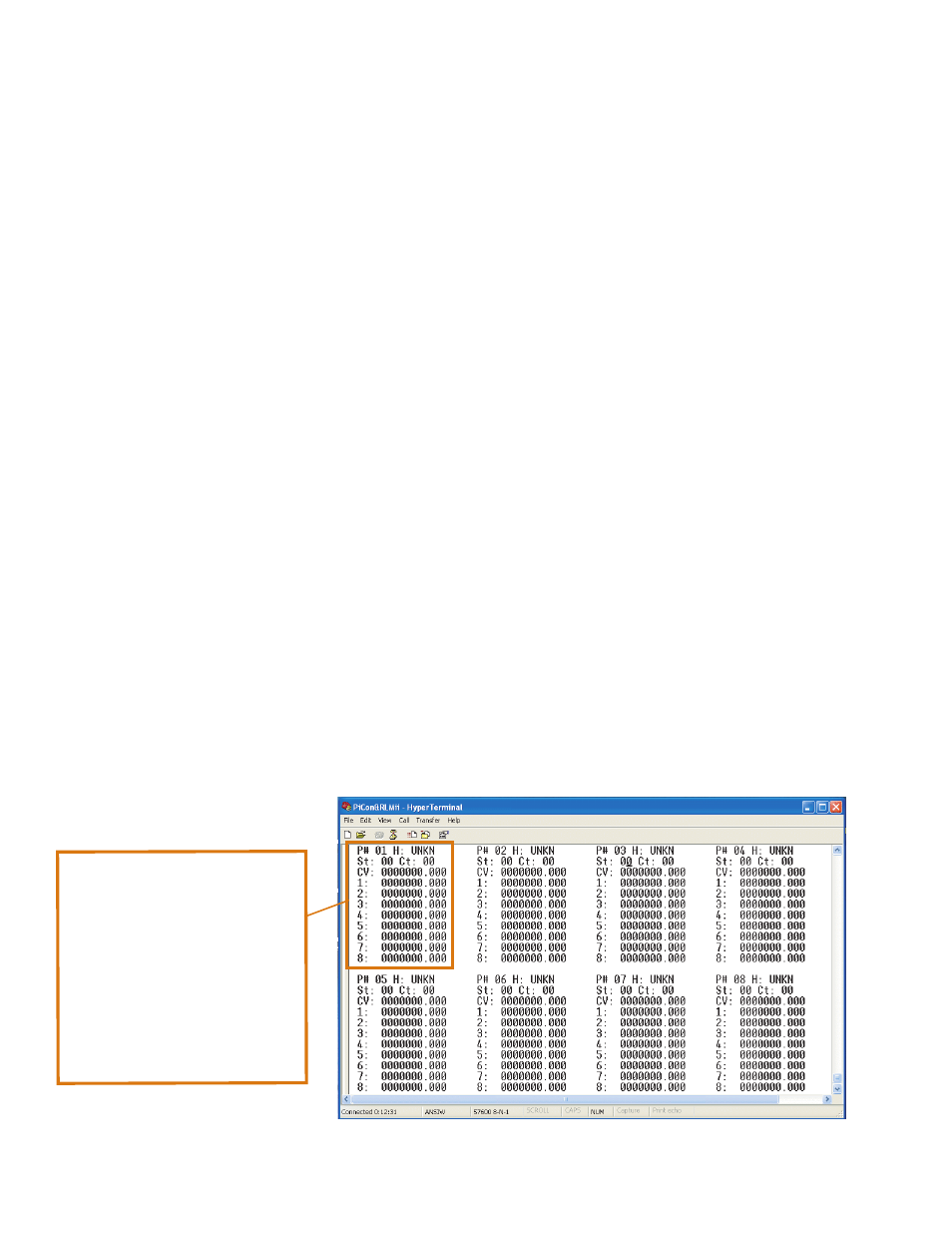

Figure 18: Pump Block Display

Each block represents a fueling

point.

Each Number (1 - 8) represents

the Grade Number.

When the dispense is complete,

the volume will drop in one of the

grade numbers. This confirms the

grade number of the product that

was dispensed.