GE Industrial Solutions EntelliGuard 800–2000 A Frames, 240–600 Vac Maintenance Manual User Manual

Page 50

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 8. Accessory Maintenance

40

Figure 48. Shunt Trip connections to the auxiliary switch and

secondary disconnect.

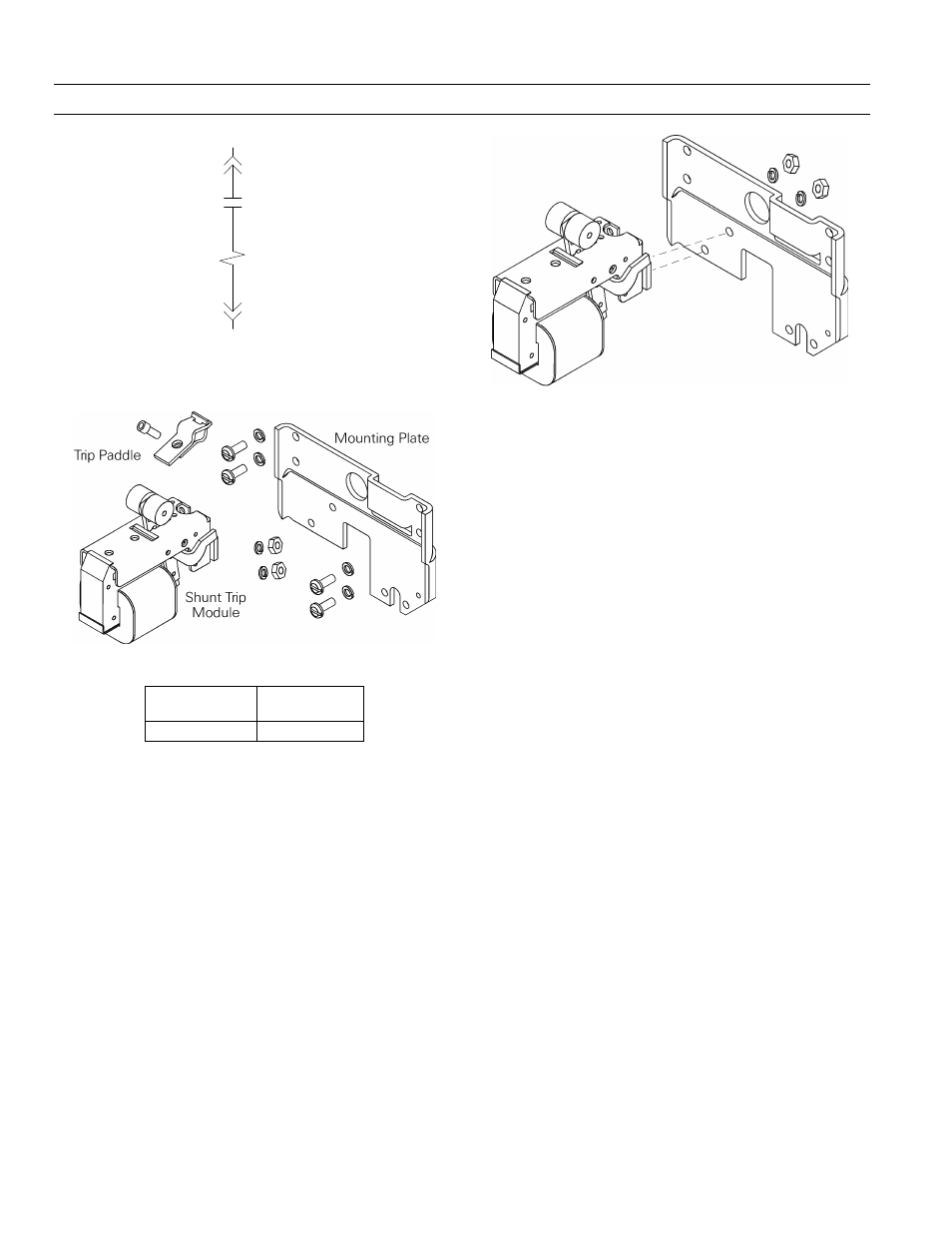

Figure 49. Shunt trip accessory kit.

Catalog

Number

Voltage

Rating

WPS1SF60120 120 Vac, 60 Hz

Table 7. Catalog number and operating voltage for the Shunt Trip

accessory.

Removing the Shunt Trip

Use the following procedure to remove the Shunt Trip

module for replacement, as illustrated in Figure 50. The

mounting bracket does not normally require replacement.

1. Carefully place the breaker on a suitable working

surface, resting on the primary disconnects, so that

the bottom of the breaker is accessible.

2. Disconnect the wire at the secondary disconnect

terminal 7. Disconnect the other wire from the

auxiliary switch, terminal 3C. Bring the wires back

to the Shunt Trip, removing wire ties as necessary.

3. Remove the two nuts and washers securing the

Shunt Trip module to the mounting bracket, then

remove the module.

Figure 50. Shunt Trip module removal and installation.

Installing the Shunt Trip

Use the following procedure to install the Shunt Trip

module as a replacement, as illustrated in Figure 50.

1. Insert the two mounting studs on the top of the

Shunt Trip module into the holes on the top of the

mounting bracket and secure with the two lock

washers and nuts supplied.

2. Run one wire from the Shunt Trip module to

auxiliary switch terminal 3C. Cut all wires to the

appropriate length and crimp on the terminals

provided (the right-angle flag for the auxiliary

switch, the spade terminal for the secondary

disconnect connection).

3. Attach the wires to the breaker frame with wire ties

as appropriate.

4. To verify that the Shunt Trip will trip the breaker,

place a 0.03-inch shim between the armature and

magnet of the Shunt Trip and manually operate the

armature to trip the breaker.

5. If the breaker does not trip in this test, verify that

the mounting fasteners are tight. If they are, bend

the trip paddle on the trip shaft to slightly reduce

the distance between the trip arm of the Shunt Trip

and the trip paddle and recheck for positive trip.

Verify that there is a 0.03–0.05-inch gap between the

trip arm and the trip paddle with the breaker

closed. A gap greater than 0.05 inch is allowable

and may sometimes be necessary to prevent nui-

sance tripping.

5

7

Aux Switch

3C

3

2

1

Shunt Trip