5 breaker mechanism operation and adjustment – GE Industrial Solutions EntelliGuard 800–2000 A Frames, 240–600 Vac Maintenance Manual User Manual

Page 28

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

18

5.5 Breaker Mechanism Operation

and Adjustment

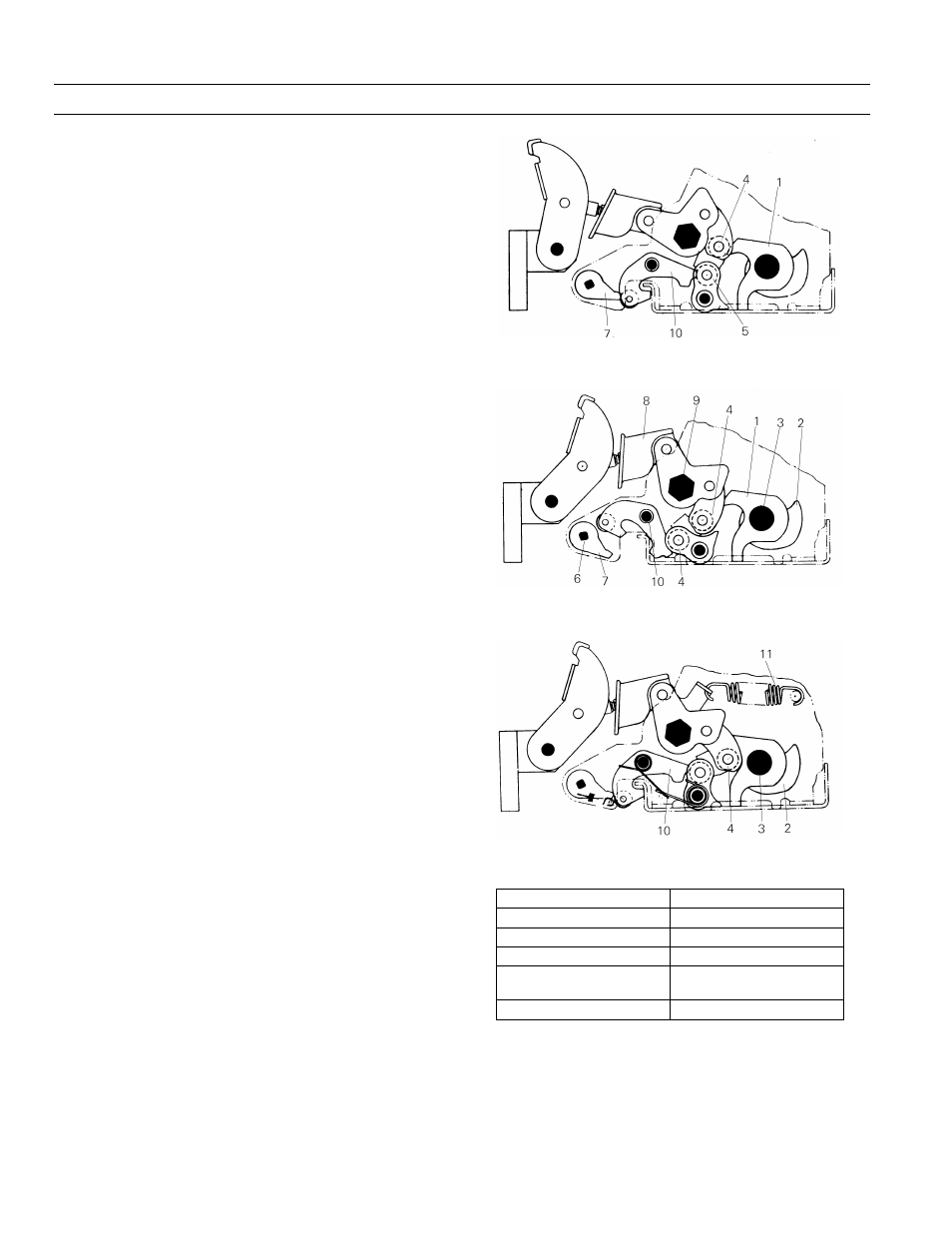

Figure 11, Figure 12, and Figure 13 show the mechanism

components in the

CLOSED

,

TRIPPED

, and

RESET

conditions, respectively. Numbers in parentheses refer to

the indicated items in the figures listed in Table 5. The

closing spring is in the charged position for all of these

details.

Closed Position

– The movable contacts are pushed against

the stationary contacts by the toggle linkage, as illustrated

in Figure 11. The toggle linkage is held in position

through the engagement of its cam roller (4), with the

prop (1), the secondary latch/roller (5), the secondary

latch (10), and the trip latch (7).

Tripped Position

– The mechanism goes from the

CLOSED

position to the

TRIPPED

position, illustrated in Figure 12,

when the trip shaft (6) is rotated by either the manual trip

button or one of the other trip devices. The trip latch (7)

is assembled to the trip shaft. When the trip shaft rotates,

the trip latch disengages from the secondary latch roller

(5). The secondary latch pivots, resulting in the collapse

of the toggle linkage. This collapse, along with the open-

ing spring (11), shown in Figure 13, causes the breaker

contacts to open.

Reset Position

– The closing cam (2), assembled to the

cam shaft (3), is rotated by the Charging Motor, manual

charging handle, or maintenance handle. The cam

engages the cam roller and partially extends the toggle

linkage. This allows the secondary latch (10) to pivot

against the front frame, as illustrated in Figure 13, leaving

a gap between the trip latch (7) and secondary latch roller

(5). The secondary latch is now in a position to engage

both the trip latch and cam roller (4).

The breaker closes when the closing springs discharge

and rotate the cam (2) against the cam roller (4). The

toggle linkage is fully extended, pivoting the secondary

latch (10) from the front frame and engaging it with the

trip latch (7) and cam roller (4), as shown in Figure 11.

When the breaker is closed and the closing spring is dis-

charged, the upper cam roller (4) is supported by the cam

(2) rather than the prop (1). The mechanism must be in

this position to check contact adjustment, as described in

Chapter 6.

Figure 11. Breaker mechanism in the CLOSED position.

Figure 12. Breaker mechanism in the TRIPPED position.

Figure 13. Breaker mechanism in the RESET position.

1 Prop

7 Trip latch

2 Cam

8 Insulated coupling

3 Camshaft

9 Main shaft

4 Cam roller

10 Secondary latch

5 Secondary latch

roller

11 Opening spring

6 Trip shaft

Table 5. Key to numbered parts in Figure 11, Figure 12, and

Figure 13.