4 draw-out mechanism – GE Industrial Solutions EntelliGuard 800–2000 A Frames, 240–600 Vac Maintenance Manual User Manual

Page 44

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 7. Maintenance of Standard Parts and Assemblies

34

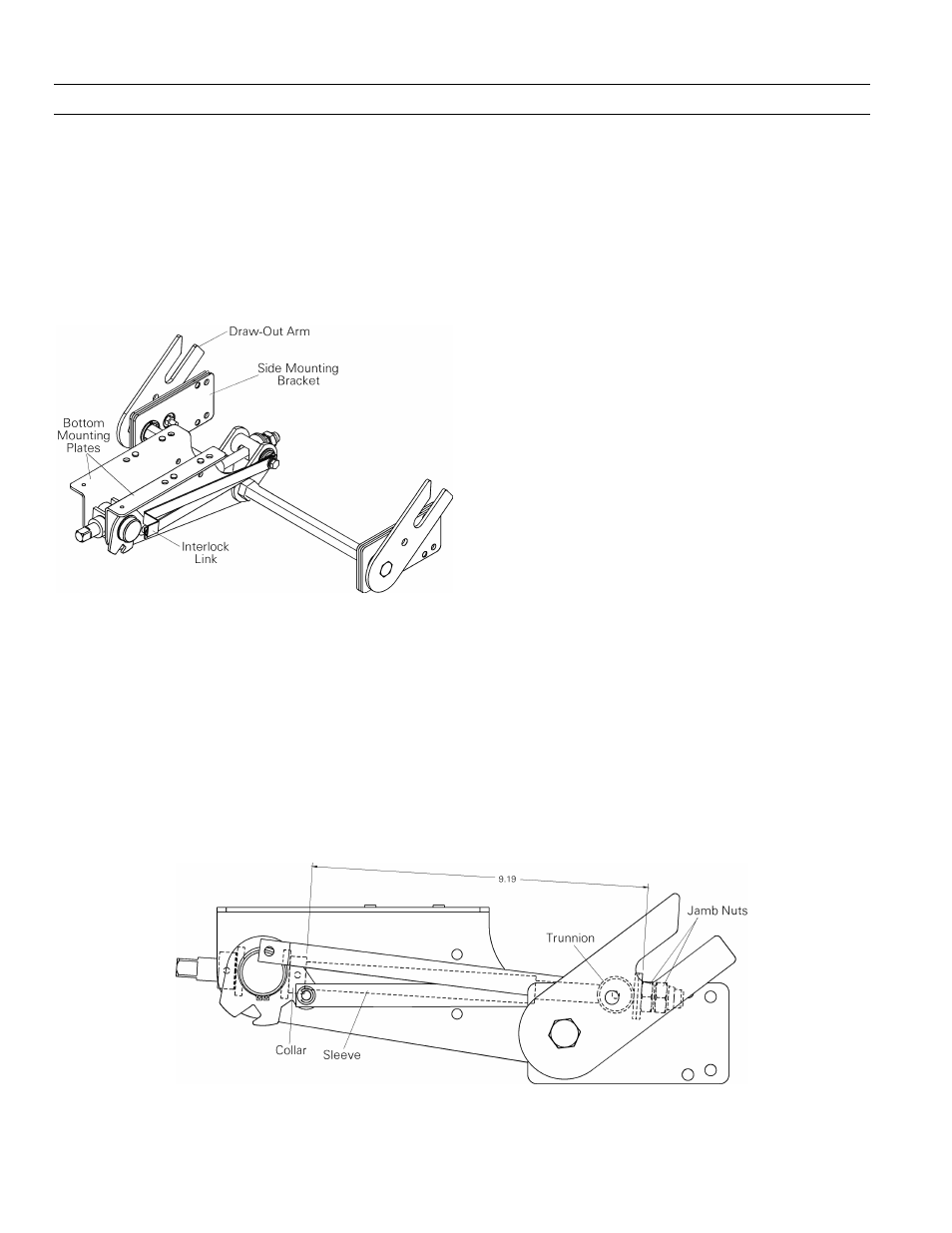

7.4 Draw-Out Mechanism

EntelliGuard circuit breakers are installed in GE

Entellisys™ Low-Voltage Switchgear. Draw-out

construction permits activation of a new feeder, allows

rapid replacement of a circuit breaker, and facilitates

inspection and maintenance of the breaker with no need

to deenergize the entire switchgear lineup. The draw-out

racking mechanism, illustrated in Figure 36, is available as

a replacement assembly.

Figure 36. Draw-out racking mechanism.

Draw-Out Mechanism Removal

The following procedure describes the removal of the

draw-out mechanism, as illustrated in Figure 38.

1. Position the breaker on a suitable work surface so

that its underside is accessible.

2. Remove the snap ring connecting the interlock link

to the breaker mechanism.

3. Remove the two bolts, lock washers, and nuts con-

necting each side mounting bracket to the sides of

the breaker.

4. Remove the four bolts and lock washers connecting

the bottom mounting brackets to the tapped holes

in the bottom plate of the breaker and lift off the

mechanism.

Draw-Out Mechanism Installation

The following procedure describes the installation of the

draw-out mechanism, as illustrated in Figure 38.

1. Put the replacement mechanism in position on the

bottom of the breaker, then insert the four bolts and

lock washers through the bottom mounting brackets

into the tapped holes in the bottom plate of the

breaker. Tighten to 96 in-lb.

2. Attach the two side mounting brackets to the sides

of the breaker with two bolts, lock washers, and nuts

each. Tighten to 96 in-lb.

3. Position the interlock link on the mounting pin of

the breaker mechanism and secure with the snap

ring.

Draw-Out Mechanism Adjustment

After installation of a replacement draw-out mechanism,

adjust the draw-out mechanism

1. With the trunnion against the jamb nut washers,

check that the distance between the edge of the

washers and the collar is 6.16 inch, as illustrated in

Figure 37. To adjust this dimension, loosen and

rotate the jamb nuts appropriately, then retighten

the nuts.

2. The length of the sleeve is adjusted to stop the

trunnion when the distance between the ends of the

equipment and breaker studs in 0.03 to 0.22 inch.

To adjust this dimension, loosen the set screw in the

collar, turn the sleeve to increase or decrease its

length appropriately, then retighten the set screw.

Figure 37. Draw-out mechanism adjustment.