3 slow closing the breaker – GE Industrial Solutions EntelliGuard 800–2000 A Frames, 240–600 Vac Maintenance Manual User Manual

Page 23

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

13

5. Push the breaker into the compartment until it

reaches the stops. This is the Disconnect position

(as shown by the legend

DISC

on the draw-out posi-

tion indicator). At this point the racking arms are

positioned to engage the fixed racking pins in the

compartment and are ready to begin the racking

motion. Push the rails back into the compartment.

6. Close the compartment door. Push the

OPEN

button

and slide the racking screw access door to the right,

exposing the racking screw.

7. Engage the Remote Racker accessory or the Racking

Handle with the racking screw. Rotate the screw

clockwise using either the Remote Racker or the

Racking Handle through the Test position, until

the racking screw comes to a solid stop. The breaker

is now in the Connected position, as shown by the

legend

CONN

on the position indicator flag. Note

that a loud click will be heard as the spring-loaded

secondary disconnect detent releases as the breaker

moves beyond the TEST position.

8. Depress the red OPEN button to close the racking

screw access door to permit breaker closing.

5.3 Slow Closing the Breaker

Closing the breaker slowly, while observing the action of

the mechanism and contacts, is a good way to judge the

correctness of mechanical and contact relationships.

Some of the maintenance procedures described later

involve slow closing the breaker. Use the following proce-

dure to slow close the breaker:

1. Remove the escutcheon. (See Section 7.5)

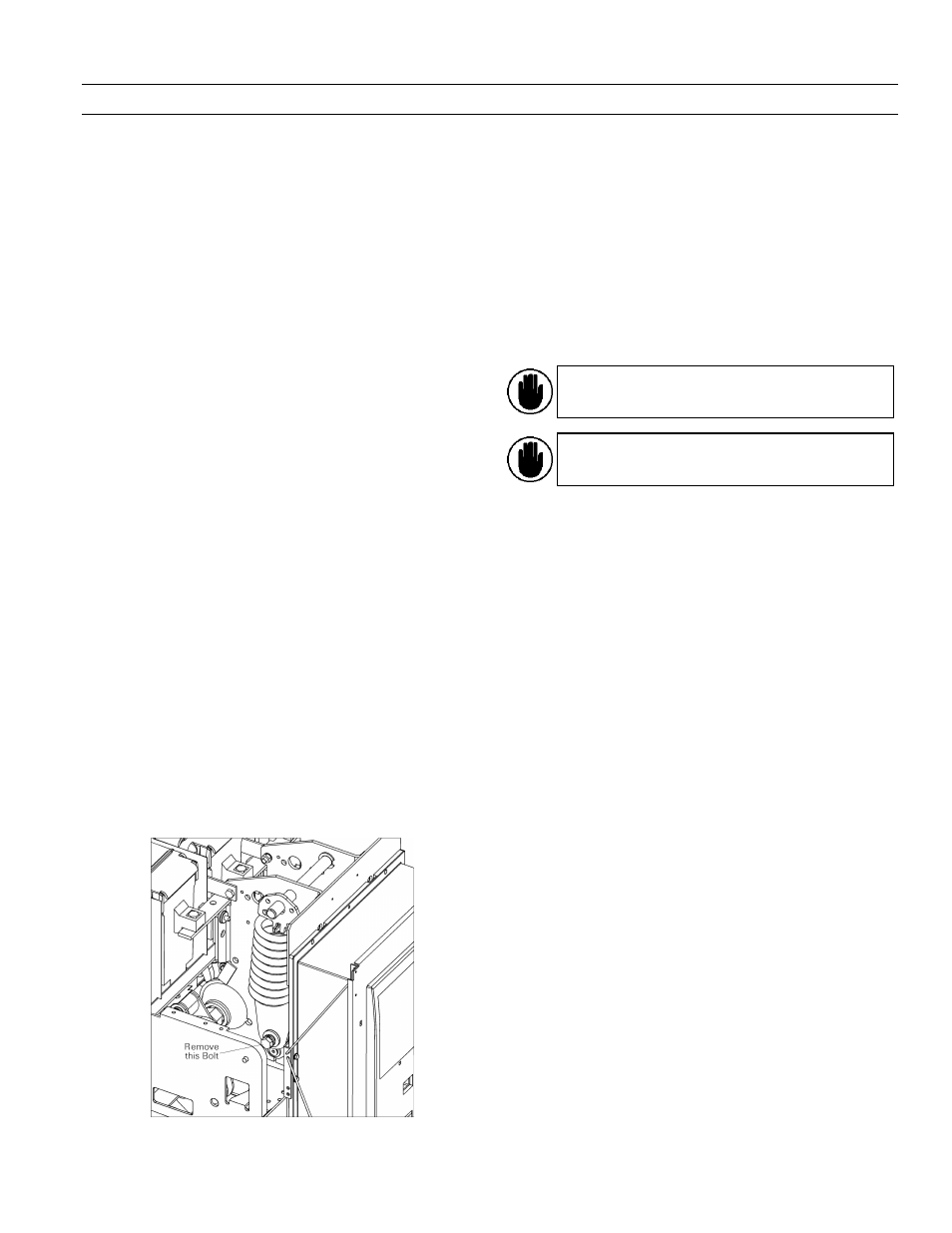

2. The closing spring must be isolated from the

mechanism camshaft. Make sure that the breaker

mechanism is

DISCHARGED

and the spring is at

minimum extension, then remove the hex-head bolt

shown in Figure 5 to disconnect the lower spring

assembly from the mating camshaft linkage.

Figure 5. Disconnecting the closing spring assembly.

3. After the bolt is removed, use the maintenance

handle (catalog number 568B386P1) to rotate the

ratchet assembly roller onto the closing prop.

4. Remove the closing prop by either pushing the

CLOSE

button or by pushing the solenoid armature

of the Remote Close.

5. Continue turning the camshaft until the contacts

and mechanism are in the fully closed position. The

cam then supports the cam roller and the contacts

develop maximum depression.

6. Push the

TRIP

button to release the mechanism and

open the contacts.

CAUTION: The mechanism and contacts will

open with normal speed and force.

ATTENTION: Le mécanisme et les contacts

s’ouvriront à une vitesse et une force normales.

When replacing the hex-head bolt, turn the camshaft with

the charging handle to align the mating holes in the

lower spring assembly and camshaft linkage. Tighten the

bolt to 360 lb-in.

5.4 Separation and Reconnection of

Front and Back Frames

Some repair operations require separation of the front

and back frames, per the following procedure. The

breaker must first be removed from its compartment, as

described in Section 5.2, and placed on a suitable work

surface.

Separation of Front and Back Frames for

EGS08, EGF08, and EGH08

The following procedure is illustrated in Figure 8.

1. Verify that the breaker contacts are open and that

the closing springs are discharged.

2. Remove the mounting bolt securing each of the arc

chutes and lift out the arc chutes. Remove the four

interphase barriers.

3. Remove the two screws and standoffs securing the

secondary disconnect to the mounting plate, taking

care to retain the spring washer from the pin on the

underside of the disconnect, as illustrated in Figure

6. Cut the wire ties securing the secondary discon-

nect leads to the mounting plate and to the breaker

back frame. Slide the secondary disconnect off the

support bracket. Secure the secondary disconnect to

the front frame assembly.

4. Remove the bolt, lock washer, and nut connecting

each tie bar to the front frame. Lift off the tie bars.