Change and cleaning of the injection nozzle, Removing the bypass t-piece, Figure 15 – M&C TechGroup DIL-1_(H) Operator's manual User Manual

Page 28: Bypass t-piece with injection nozzle and o-ring

28

Gas sampling and gas conditioning technology

2-1.1.7.6-ME

16.3

CHANGE AND CLEANING OF THE INJECTION NOZZLE

N O T E !

For cleaning the injector, it is not necessary to remove the nozzle out of the

crosspiece. The nozzle can be cleaned together with the complete cross-

piece in an ultrasonic bath.

For changing the injector nozzle, see figure 14:

Loosen nut 3 and remove jet pipe;

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Check the o-ring and change it if necessary;

Push the new nozzle with o-ring until blocking.

16.4

REMOVING THE BYPASS T-PIECE

For cleaning or changing the bypass injector, the bypass T-piece can be completely disassembled.

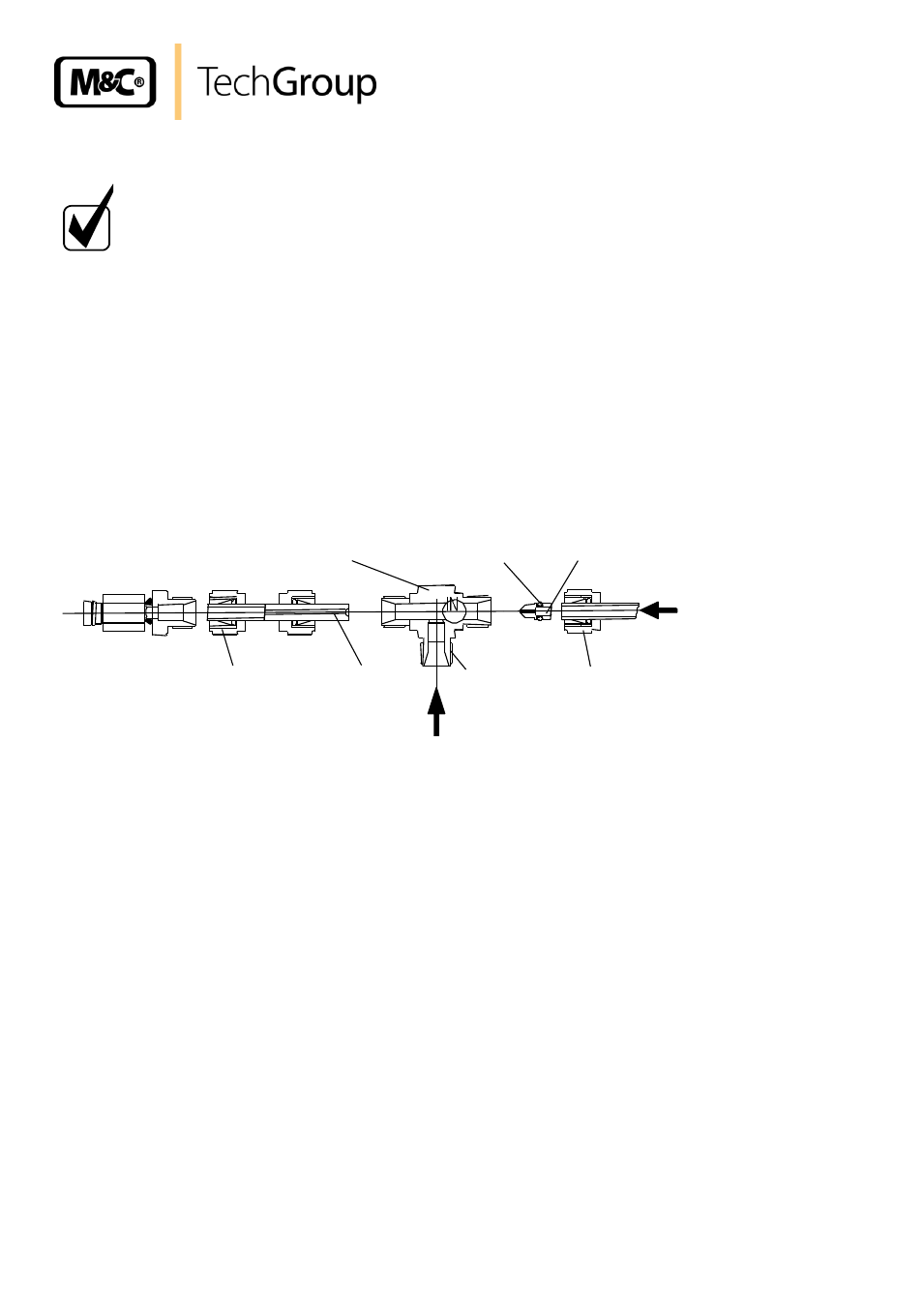

The following figure shows the bypass T-piece.

Injection nozzle

O-ring

Bypass T-piece

Jet pipe

Nut 2

Nut 1

Nut 3

Sample gas

Dilution gas

Figure 15

Bypass T-piece with injection nozzle and o-ring

Dismantle the T-piece as follows:

Romove insulation cover if applicable;

Remove all tube connectors on the bypass-T. These are: (see figure 15):

- Bypass inlet union nut 1

- Union nut 2 (jet pipe side)

- Union nut 3 (sample inlet).

The bypass-T is now ready for further maintenance and repair.

16.5

CHANGE AND CLEANING OF THE BYPASS INJECTION NOZZLE AND CON-

TROL OR CHANGE OF THE O-RING

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Check the o-ring and change if necessary;

Push in the new or cleaned old nozzle with o-ring until blocking.