Figure 11, Extract from the injector data sheet, Figure 12 – M&C TechGroup DIL-1_(H) Operator's manual User Manual

Page 23

23

Gas sampling and gas conditioning technology

2-1.1.7.6-ME

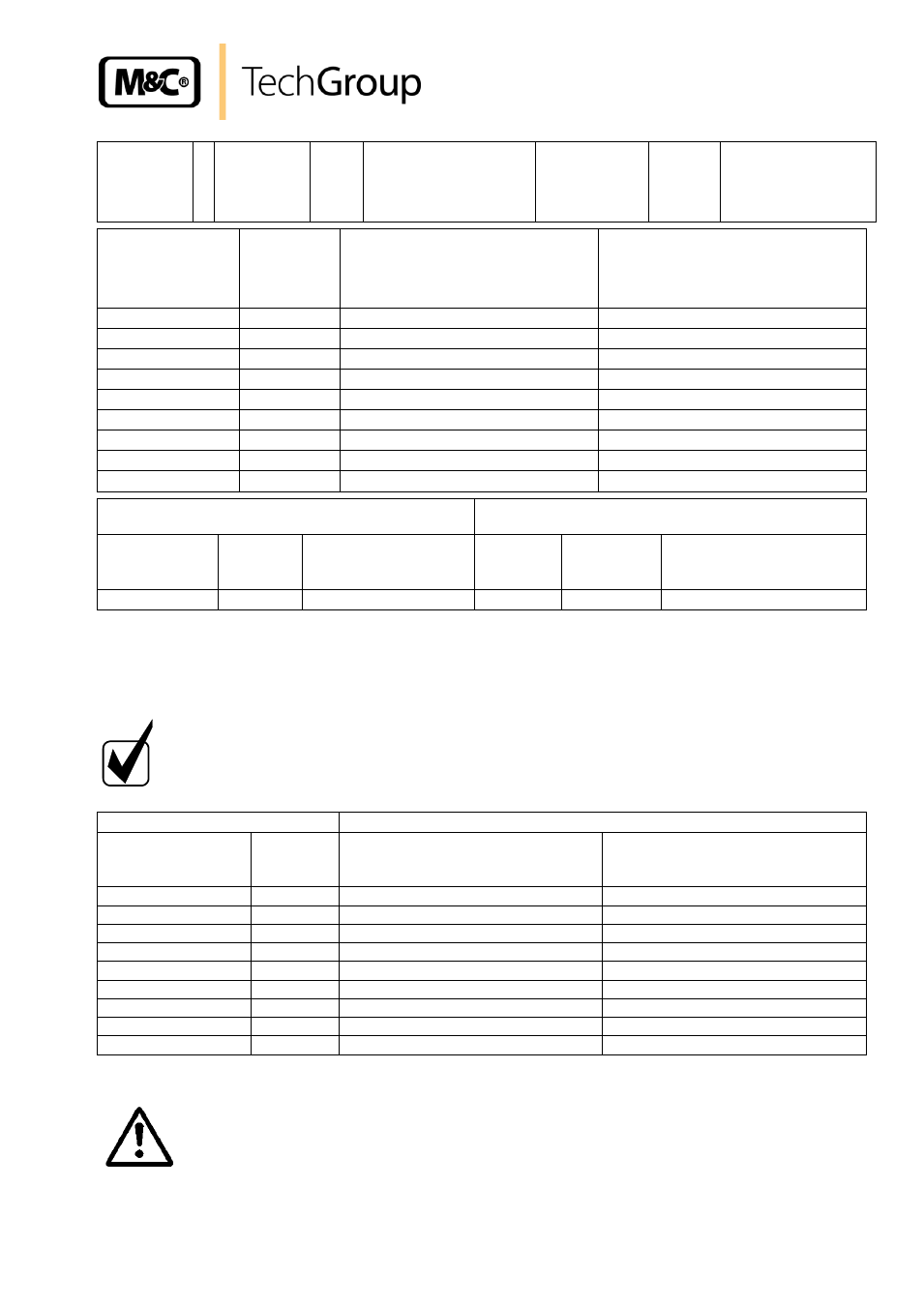

Injektortyp

I

Injektor-Nr.

689

Für Verdünnungs-

system-Nr.

8652/222835

Typ

DIL-1/H-A1

Injector

type

Injector

No.

For dilution system

No.

Type

Betriebsdruck

Operating pres-

sure

[bar]

Durchfluss

Flow

[l/h]

Unterdruck ohne kritische Düse

Vacuum without critical orifice

[bar]

Unterdruck mit kritischer Düse

Vacuum with critical orifice 5,1l/h

[bar]

2,4

415

-0,62

-0,61

2,6

435

-0,65

-0,64

2,8

460

-0,68

-0,67

3,0

490

-0,80

-0,77

3,2

510

-0,79

-0,77

3,4

535

-0,79

-0,77

3,6

560

-0,78

-0,76

3,8

585

-0,77

-0,76

4,0

605

-0,77

-0,75

Überprüfung des Verdünnungsfaktors

Check of the dilution ratio

Messgasdruck atmosphärisch

Sample gas pressure atmospheric

Kritische Düse

Critical nozzle

Verd.gas

Dilution

gas

Verdünnungsgasdruck

Dilution gas pressure

Messgas

Sample

Verdünnung

Dilution

Messwert d. verd. Gases

Meas. value of the dil. gas

5,1 l/h

100% N

2

3,2 bar

100% O

2

100:1

1,0 % O

2

Figure 11

Extract from the injector data sheet

For the operation of an installed bypass injector, the necessary pressure must be set on the pres-

sure regulator (see figure 12).

N O T E !

The attached bypass injector table shows the suction flows at cor-

responding bypass gas pressures for two different process pres-

sures, 1 bar and 0,9 bar absolute (see figure 12).

Bypassgas / Bypass gas

Prozessgas / Sample gas

Betriebsdruck

Operating pressure

[bar]

Durchfluss

Flow

[l/h]

Ansaugvolumenstrom bei 1bar abs.

Suction flow at 1bar abs.

[l/h]

Ansaugvolumenstrom bei 0,9bar

abs.

Suction flow at 0,9bar abs. [l/h]

0,5

110

45

-

1,0

155

115

-

1,5

190

200

65

2,0

235

250

135

2,5

270

300

200

3,0

310

350

250

3,5

355

370

270

4,0

395

390

305

4,5

430

425

350

Figure 12

Suction flow at 0,9 or 1bar abs. in dependence on the bypass gas pressure

W A R N I N G !

In the event of low temperature (failure of the heating) the supply of

dilution gas must be interrupted!