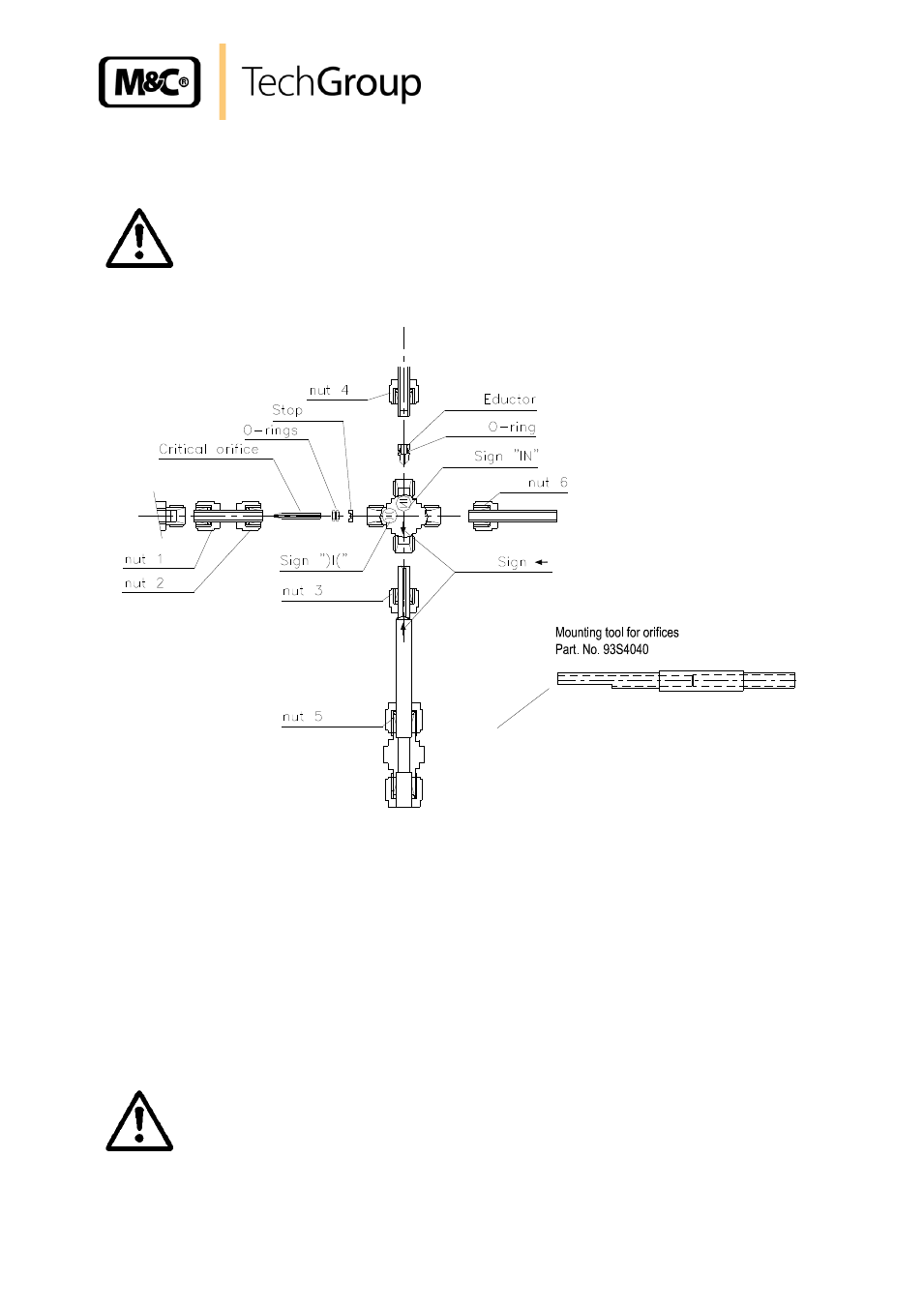

Figure 14, Crosspiece with critical orifice and o-ring seals – M&C TechGroup DIL-1_(H) Operator's manual User Manual

Page 27

27

Gas sampling and gas conditioning technology

2-1.1.7.6-ME

16.2

CLEANING OF THE CRITICAL ORIFICE AND CHECK OR CHANGE OF THE O-

RINGS

W A R N I N G !

Do not clean the critical orifice mechanically.

Cleaning should be effected in an ultrasonic bath !

Figure 13 shows the position of the orifice in the crosspiece and the O-ring seals.

Figure 14

Crosspiece with critical orifice and O-ring seals

Please proceed as follows:

Loosen union nut 3 and remove the jet pipe;

Loosen nut 2 and remove the pipe piece with both nuts;

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Push the critical orifice with its nozzle seat and o-ring carefully from the back side of the cross-

piece by using the mounting tool (item 8, figure 14);

Check the o-rings and change them if necessary;

Push the new orifice or the cleaned old one into the o-rings until block.

Now, the dilution unit can be reassembled in reverse order.

W A R N I N G !

The Swagelok

®

fittings must be carefully tightened to avoid damage

of the internal components. Do not tighten the fittings too fast.

If a fitting is believed to be leaking, do not tighten further. Disas-

semble the fitting completely and tighten it again.

8