M&C TechGroup EC-30_FD Operator's manual User Manual

Page 25

25

Gas sampling and gas conditioning technology

3-4.20-ME

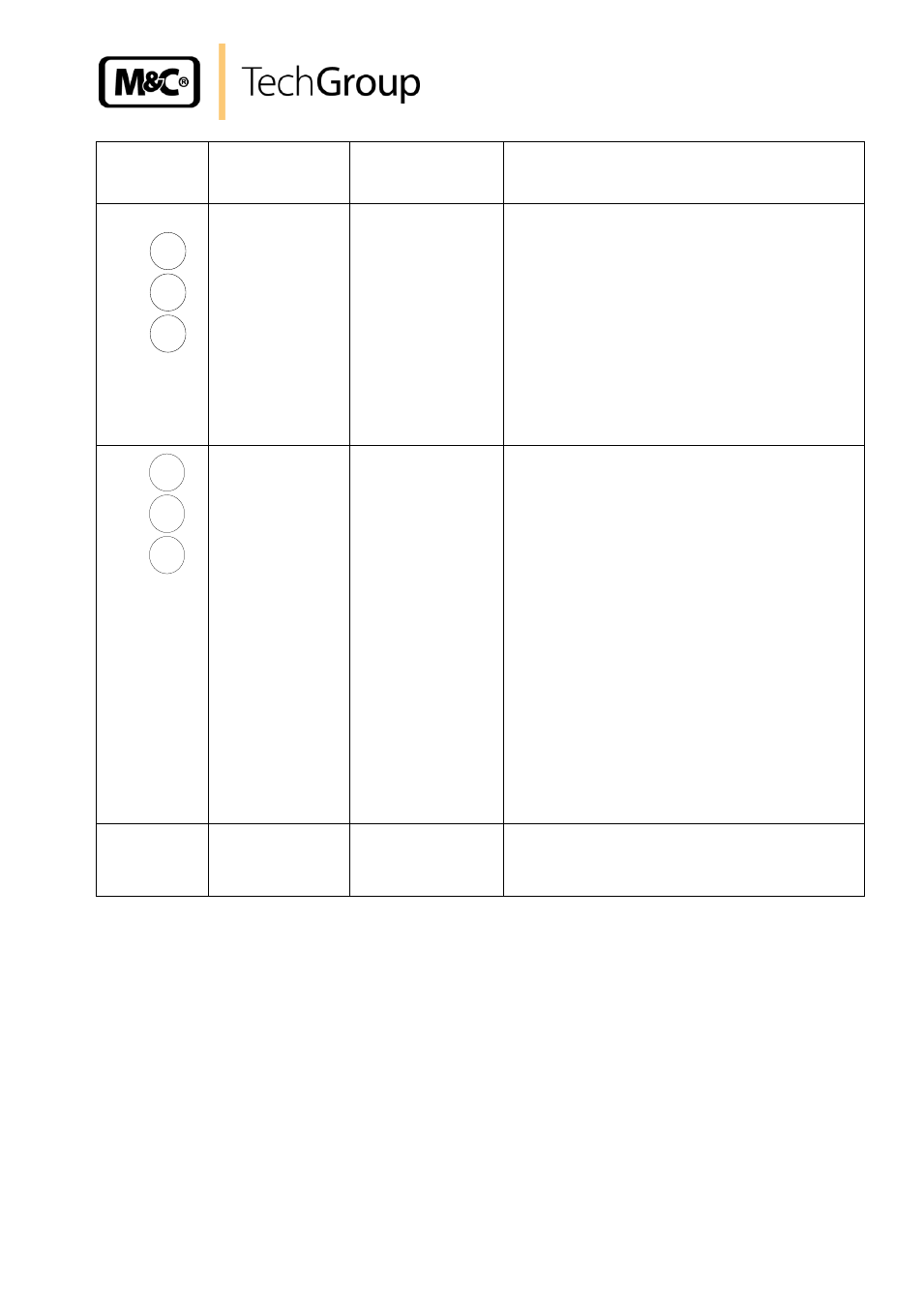

LED display Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

green

red

Equipment does

not cool;

Cooler has been

over-cooled (temp.

< - 2°C);

Ambient

temperature < -2°C

Cooling compressor

stopped;

Cooling compressor

runs continuously;

Ambient temperature must be ≥ +5°C!

Check temperature at EC automatic control board

(18.2);

If temperature < -2°C (< -0,2V):

Check PT100 temperature sensor (19.1);

If not OK:

Replace sensor.

Solid-state relay defective;

Replace EC automatic control board;

Low-temperature

function affected;

Low temperature

stages defective

Sensors;

Peltier elements;

Check the fine fuses in the EC30 mains supply;

if o.k.:

Check the voltage at pins 20/21 and 21/22 of the

EC30 automatic control board (Fig. 15);

if voltage > 12V:

Check the voltage for the EC30 temperature

sensors on the EC30 control board at pins 27/28

and 33/34 (19.2);

if voltage > 2,83V (> +10

C):

Replace the relevant sensors;

if voltage < 2,83V (< +10

C):

Check the voltage of the Peltier elements at pins

23/26, channel , and pins 29/32, channel (Fig.

15)

if voltage for channel thus controlled (LED D16/

D17) = 13VDC:

Peltier element is defective; send cooler in for

repair;

Heat

exchanger

frozen up

No gas flow,

sample gas pump

runs;

Peristaltic pump

defective;

Gas flow too low

Check peristaltic pump SR25.1

if o.k.:

Raise gas flow to min. 100l/h;

°C >

ON

°C <

green

pink

red