Function, Figure 3, Schematic diagram of functioning of heat exchanger – M&C TechGroup EC-30_FD Operator's manual User Manual

Page 12: 10 function

12

Gas sampling and gas conditioning technology

3-4.20-ME

The EC30 is equally suitable for wall installation or mounting in a

19” rack. The versions differ in the

positioning of the LED function display . While for wall installation the LED function display can be

fitted into the corresponding cut-outs in the EC30

front panel, for 19” rack mounting this is done using

the cut-outs in the back panel of the casing. This positioning is done at the factory when stating the

type of installation of the EC30 gas cooler. It is relatively simple to subsequently reconfigure it on site

at the user location. The location for installation of the LED function display is marked

correspondingly.

On the upper side of the cooler casing you will see the cut-outs for the heat exchangers of the pre-

cooling stage and for the two low-temperature stages and . Sample gas enters the pre-cooling

stage at the 4/6 hose connection on the upper part of the heat exchanger. At the rear part of the

casing the condenser to remove heat given off in the compressor can be seen. The mains power

connector, EC automatic control board and EC30 control board with the contact outputs for the status

alarm are located in two plastic housings respectively behind the removable front panel of the EC30

casing.

On the underside of the casing the following connections are provided as standard: cable glands

PG13,5 to the plastic housings ; condensate outlets GL25/12 from the heat exchangers ,

and ; sample gas outlet DN4/6.

As standard, the condensate is removed externally with collecting vessels, peristaltic pumps, or by

”over-pressure operation”, with automatic float condensate traps, as e.g. type AD-... The heat energy

from the cooling system is drawn off by a forced-ventilation . The required fans and large air

suction filter elements are provided as standard in universal unit EC-f . This is arranged below the

EC30 casing and is absolutely essential for operation of the cooler unit. Optionally, the universal unit

EC-F can be replaced by an automatic condensate removal unit EC-FD , which is likewise located

below the casing of the cooler. Apart from the above-mentioned condenser forced ventilation, the EC-

FD unit has three peristaltic pumps of type SR25.1 for automatic condensate removal. This can also

be set in underpressure operation (suction operation).

The connections for the sample gas outlet and the condensate outlet are located in the front

panel of the EC-FD unit.

10

FUNCTION

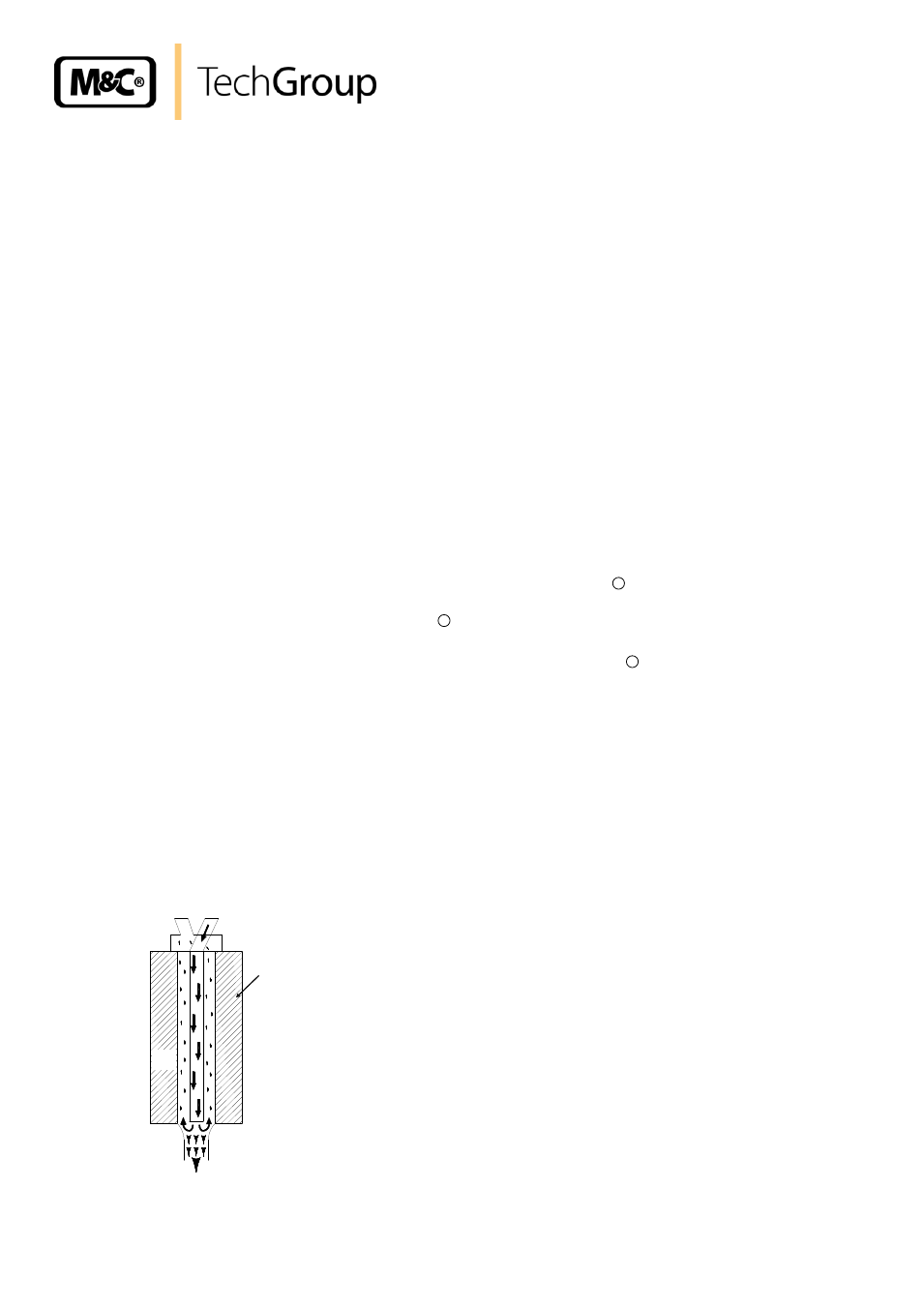

The patented M&C EC30(/FD) gas cooler is a combined two stage compressor Peltier cooler with

status alarm capability. Automatic defrosting of the double-construction low temperature stage ensures

100% availability of the cooler. The pre-cooling stage (see fig. 1) of the cooler is equipped with a jet

stream EC heat exchanger made of Duran glass. Figure 3 shows a schematic diagram of the

functioning of the heat exchanger.

+5°C

Sample gas

out

Sample gas

in

Condensate out

Cooling-

block

Figure 3 Schematic diagram of functioning of heat exchanger

13

11

12