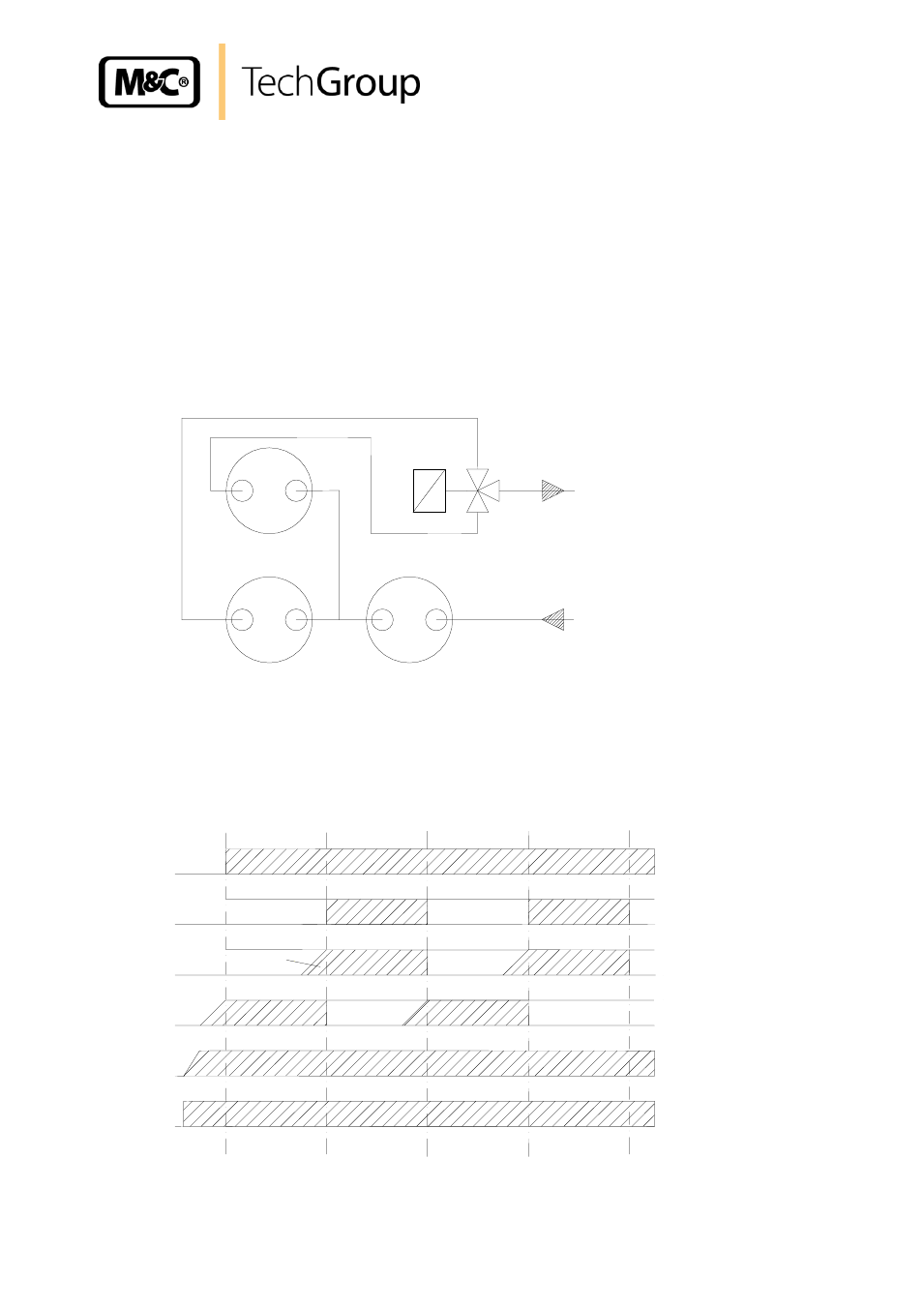

Figure 4, Tubing of the heat exchangers, Figure 5 – M&C TechGroup EC-30_FD Operator's manual User Manual

Page 13: Timing schematic of the switching processes

13

Gas sampling and gas conditioning technology

3-4.20-ME

A decoupled compressor cooler system has a heat-insulated cooling block at a constant temperature

of +1

C. Control of the compressor is contactless done by the EC automatic control electronics and is

therefore not subject to wear. The pre-cooling stage ensures that the greater part of the condensate

has already been removed from the gas stream.

The low-temperature stages are provided with two modified jet stream EC30 heat exchangers made of

Duran glass. These are cooled down to a temperature of around -30

C by two completely independent

Peltier element cooling systems.

Stages

and

(see fig. 1) of the gas cooler work intermittently at intervals of three hours. While one

stage is in operation, the other one is automatically defrosted. All the heat exchangers are easily

accessible and are arranged in such a way that they can be removed very simply. Switching over the

gas flow is done by a 3/2-way solenoid valve made of PVDF/Viton (see fig. 4). This arrangement

excludes any possibility of water vapour being sucked back from the low-temperature stage that is

being defrosted.

Figure 4 Tubing of the heat exchangers

The EC30 control electronic switches the solenoid valve every three hours and at the same time

carries out the alternating defrosting

process of the low-temperature heat exchangers.

Figure 5 Timing schematic of the switching processes

Solenoid valve

Channel 2

Channel 1

Temperature channel 2

Temperature channel 1

EC pre-cooler

Ambient temperature

Power OFF

Power ON, start

1 hr

3 hr

3 hr

3 hr

3 hr

Status

o.k.

Alarm

-30°C

+5°C

-30°C

+5°C

+1°C

Sample gas

IN

Sample gas

OU

T

Pre-cooling stage

Deep cooling stages