Trouble shooting – M&C TechGroup EC-30_FD Operator's manual User Manual

Page 24

24

Gas sampling and gas conditioning technology

3-4.20-ME

17

TROUBLE SHOOTING

Troubleshooting is made much easier by the LED function display.

The following table shows possible reasons for error and how to correct them (not applicable for the

running-up phase of the cooler).

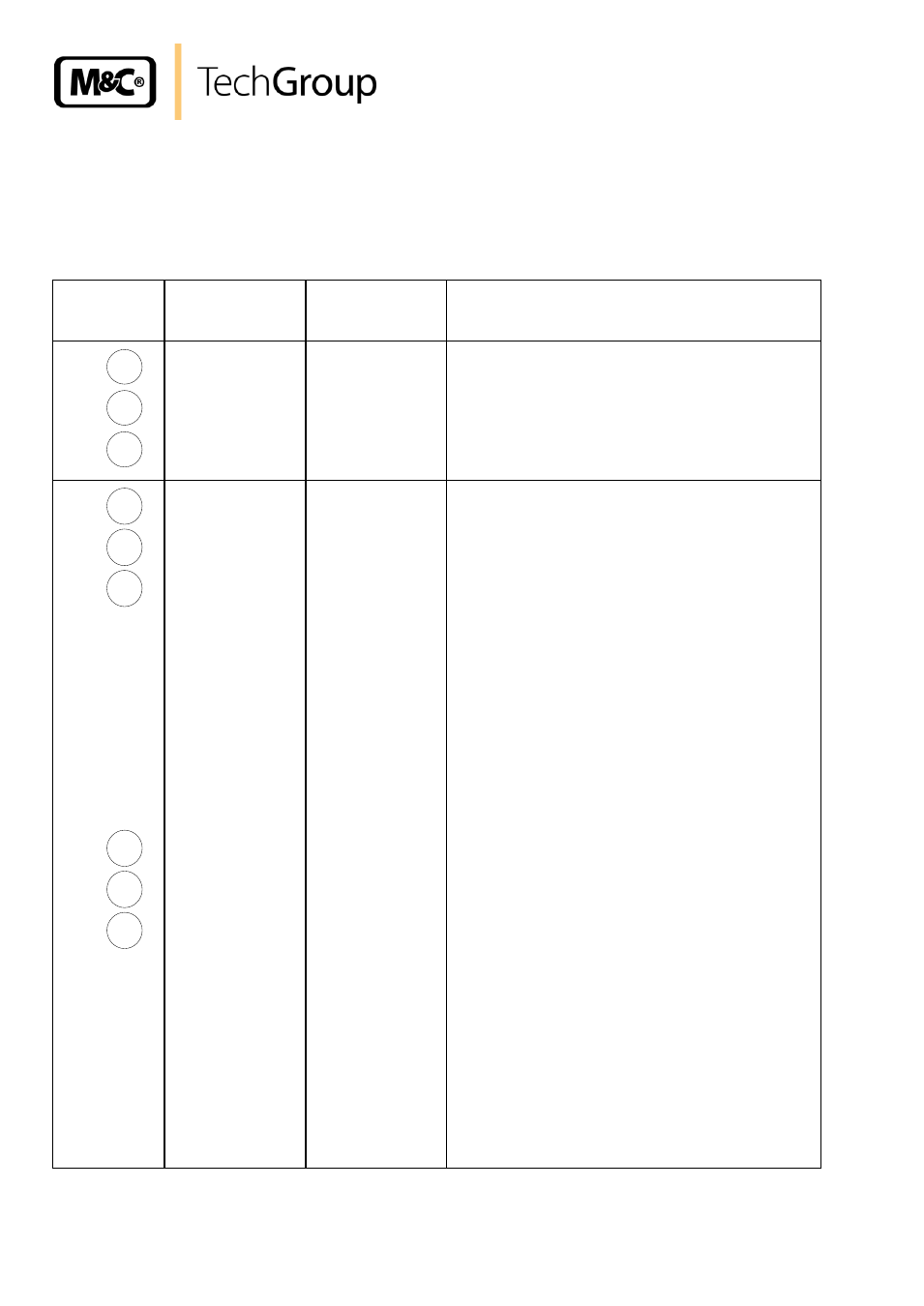

LED display Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

Equipment

does not cool;

No mains power;

Check the mains voltage 230V (115V) at terminal X0

(see Fig. 6 and 7);

If mains voltage OK:

replace defective EC automatic control board.

°C >

ON

°C <

red

pink

Equipment does

not cool or the

cooling is

insufficient;

Cooling compres-

sor is not running;

Check that the plugs are firmly seated in the sockets

for power connection to the compressor;

If OK:

Measure the voltage 230V/115V for the compressor

at the EC automatic control board at pins 21 and 22

(see Fig. 9).

If not OK:

Replace the defective EC automatic control board;

If OK:

Does the red LED D3 (see Fig. 9) on the EC

automatic control board lights up for more than one

second?

(A blocked unit will be switched off by the motor

breaker switch);

If yes:

Replace the starting condenser;

If compressor does not run:

Send cooler in for repair.

°C >

ON

°C <

red

pink

See above

Cooling compres-

sor runs; over-loa-

ding of the cooler

unit;

Check:

- Is the maximum of 250 l/hr of gas flowing?

- Is the ambient temperature max. +45°C?

- Are the air suction filters dirty?

- Are the fans working?

- Are the condenser fins contaminated?

If OK:

Check temperature at the EC automatic control

board (18.2);

If the temperature is < 4°C (< 0,4V) for a nominal

set temperature of +1°C:

Replace EC automatic control board;

If temperature > 4°C (>0,4V):

Check PT100 temperature sensor (19.1);

If not OK:

Replace sensor;

If sensor and electronics OK:

Send cooler in for repair.