Rip cutting – Grizzly G0623X3 User Manual

Page 45

Model G0623X/G0623X3 (Mfg. Since 5/12)

-43-

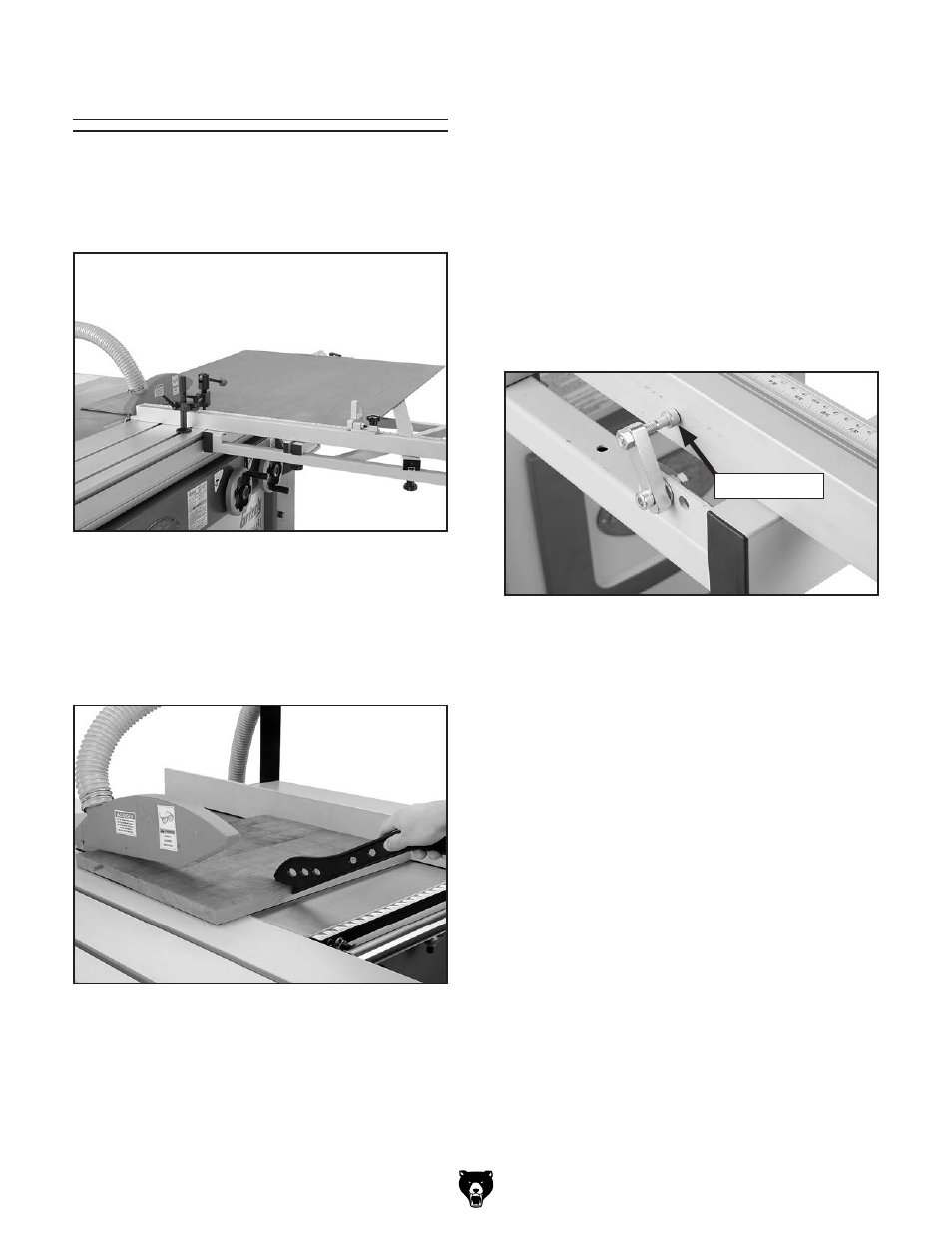

this saw has the capability of rip cutting large

panels (

figure 72). the sliding table removes the

burden of sliding a large and heavy panel over a

stationary table surface.

this saw also has the capability of rip cutting

smaller boards, using the machine as a traditional

table saw (

figure 73). smaller, lighter boards

are easier to slide across the stationary cast iron

table surface to the right of the saw blade.

rip cutting

figure 72. rip cutting with the sliding table.

figure 73. traditional rip cutting.

determine which cutting operation will be best

suited for the workpiece to be ripped.

•

to use the sliding table, read the instructions

titled “rip Cutting w/sliding table.”

•

to use the machine as a traditional table saw,

skip ahead to “rip Cutting w/rip fence.”

rip cutting with sliding table

1. install the crosscut fence on the crosscut

table, and rotate it until the fence touches the

90° stop bolt (

figure 74).

2. Check to make sure the fence is at 90˚ and, if

necessary, adjust it as described in

squaring

crosscut fence to blade on page 70.

3. slide the fence so the plastic block on the end

is next to the blade teeth—this calibrates the

scale to zero—then tighten the lock knob.

note: Avoid cutting the plastic block on the

end of the fence.

4. set a flip stop to the desired width-of-cut.

5. position the blade guard to the correct height

for your workpiece.

6. load the workpiece onto the table saw. the

set up should look similar to

figure 72.

7. take all the necessary safety precautions,

then perform the cutting operation.

figure 74. Crosscut fence mounting locations.

90° stop bolt