Eaton Compressor & Fabrication C-STOV-MC001-E1 User Manual

Page 8

8

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

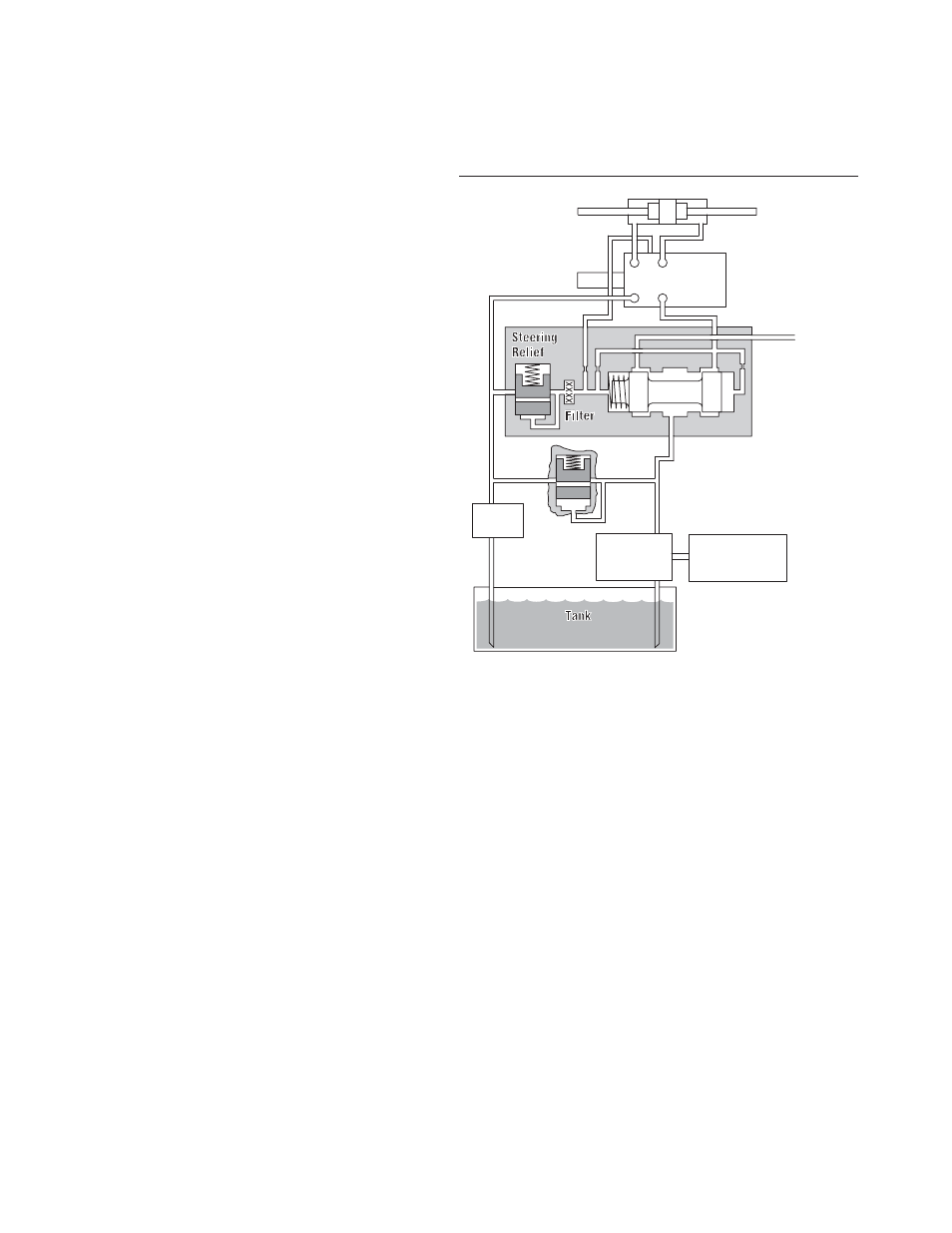

Hydraulic Circuit

Explanation

Neutral Circuits:

Load Sensing

Load Sensing Circuits

Char-Lynn load sensing

power steering uses

conventional or load sensing

power supplies to achieve

load sensing steering. The

use of a load sensing

steering unit and a priority

valve in a normal power

steering circuit offers the

following advantages:

• Provides smooth

pressure compensated

steering because load

variations in the

steering circuit do not

affect axle response or

maximum steering rate.

• Provides true power

beyond system

capability by splitting

the system into two

independent circuits.

Pressure transients are

isolated in each circuit.

Only the flow required

by the steering

maneuver goes to the

steering circuit. Flow

not required for

steering is available for

use in the auxiliary

circuits.

• Provides reliable operation

because the steering

circuit always has flow

and pressure priority.

Char-Lynn load sensing

steering control units and

priority valves can be used with

open center, closed center or

load sensing systems. Use in

an open center system with a

fixed displacement pump or a

closed center system with a

pressure compensated pump,

offers many of the features of a

load sensing system. Excess

flow is available for auxiliary

circuits.

Listed below are the

components of a typical load

sensing control circuit and a

brief application description.

Pump—May be fixed

displacement, pressure

compensated,

or flow and pressure

compensated design.

Priority Valve—Sized for

design pressure drop at

maximum pump output flow

rate and priority flow

requirements. The minimum

control pressure must assure

adequate steering flow rate

and must be matched with

the steering control unit.

A dynamic signal priority

valve must be used with a

dynamic signal steering

control unit.

Steering Control Unit—

Designed for specific rated

flows and control pressures.

It must be matched with a

control pressure in the

priority valve to obtain

maximum steering rates.

Higher flow rates require

higher control pressures.

Neutral internal bleed

assures component

temperature equalization.

LS Line—A LS line is always

needed to sense pressure

downstream from the

variable control orifice in the

steering control unit. This is

balanced by an internal

passage to the opposite side

of the priority control spool.

The total system

performance depends on

careful consideration of the

control pressure chosen and

pressure drop in the CF line.

Steering Relief Valve—

Must be factory set at least

10 bar [145 PSl] above the

maximum steering cylinder

pressure requirement. Most

of the flow will be directed

to the auxiliary circuit (EF)

when the relief setting is

exceeded.

System Main Relief

Valve—A pressure relief

valve for the auxiliary circuit

and/or a main safety valve for

the protection of the pump is

recommended and sized for

the maximum pump output

flow rate. If a main relief valve

is used, it must be set above

the priority circuit steering

relief valve pressure setting.

Filter

Pump

Prime Mover

Main

Relief

Manual

Input

Steering Cylinder

Load Sensing

Steering Unit

T

LS

T

P

L

R

Priority Valve

High Pressure

Carryover

P

CF

EF

DS

LS

PP

Dynamic Signal

LS — Load Sensing

DS— Dynamic Signal

PP — Pilot Pressure

CF — Control Flow

EF — Excess Flow