Special features and application dual displacement – Eaton Compressor & Fabrication C-STOV-MC001-E1 User Manual

Page 15

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

15

Special Features

and Application

Dual

Displacement

Description

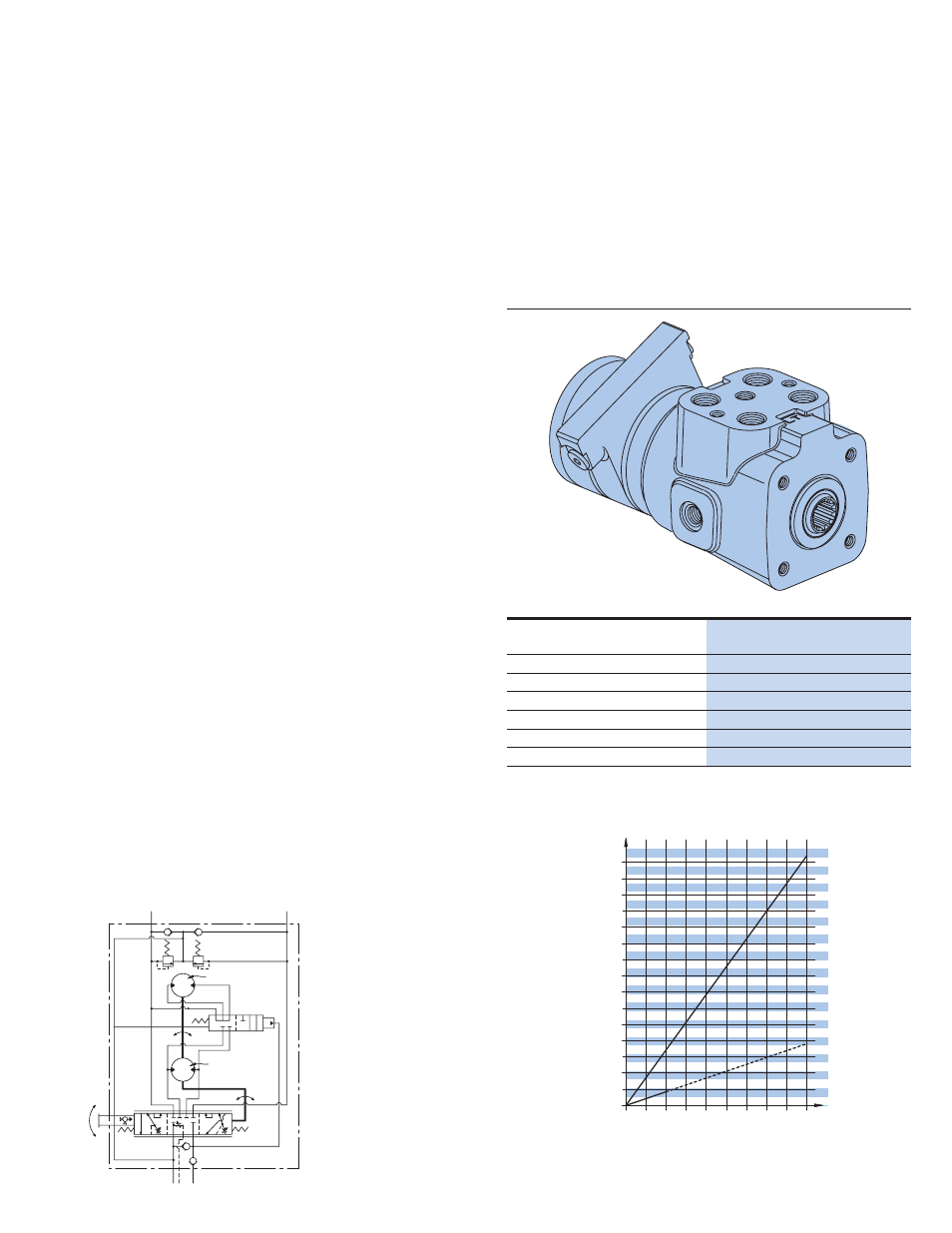

The dual displacement

steering control unit allows

manufacturers of off road

vehicles to retain manual

steering capabilities while

reducing the number of

components in their system.

By using two displacements

in one unit we offer a better

solution to manually steer a

vehicle in an unpowered

mode without the need of a

back-up power system—

resulting in a more

economical machine.

The dual displacement

steering unit uses two

gerotors and a pressure

controlled logic valve. The

logic valve switches between

two displacements, one

displacement for manual

steering and the total of both

displacements for powered

operation. The logic valve is

spring returned to the

smaller manual

displacement when inlet

pressure falls below 8 bar

[120 psi]. Above 8 bar [120

psi] the logic valve connects

both gerotors to provide full

powered displacement.

Manual steering capabilities

in unpowered mode

• Eliminates the need of

a back-up emergency

system.

• Engages the small

displacement in an

unpowered mode and

allows manual steering.

• Allows vehicles to meet

ISO/TUV road regulations

without the need of the

currently used

emergency system.

Performance in powered mode

• Both gerotors are

engaged to steer the

vehicle.

• Same performance as

other Char-Lynn

steering units.

Additional Features

• Steering circuit: Load

Sensing Dynamic Signal

• Max. system pressure:

241 bar [3500 psi].

• Valve options and other

features: same as those

available on Series 10

(single displacement)

units

DISPLACEMENT CHART:

Gerotor 1

Gerotor 1 and 2

Gerotor 1

Gerotor 1 and 2

Manual displ.

Powered displ.

Manual displ.

Powered displ.

in

3

/rev

in

3

/rev

cm

3

/rev

cm

3

/rev

3.6

9.5

60

156

3.6

10.9

60

179

3.6

12.5

60

205

3.6

13.3

60

218

3.6

14.9

60

244

For any other displacement please see your Eaton Representative.

0

0

15

Input Speed RPM

Manual 60 cm

3

/r [3.6 in

3

/r]

Powered 244 cm

3

/r [14.9 in

3

/r]

Flow vs RPM (for each operating mode)

S

tee

ring Flow

G

PM

S

tee

ring Flow l/min

30

45 60

75 90

60 105 120

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

0.5

1.0

1.5

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.5

6.0

7.0

7.5

Powe

red Mode

Po

w

er

ed

M

od

e

Powe

red Mode

Manual Mode

Man

ual

Mod

e

Manual Mode

2.0

T

LS

P

Added Gerotor

Logic Valve

Manual Gerotor

R

L