Procedure, Drill head position, Jt25 operator’s manual – Ditch Witch JT25 User Manual

Page 98

JT25 Operator’s Manual

Conduct a Bore - 97

Correct Direction

CMW

Procedure

1.

Locate drill head. Take readings available with your beacon and tracking equipment such as:

•

depth

•

pitch

•

left/right information

•

temperature

•

beacon roll

2.

Compare position to bore plan. Determine direction drilling should go.

3.

Position drill head.

4.

Drill in pipe.

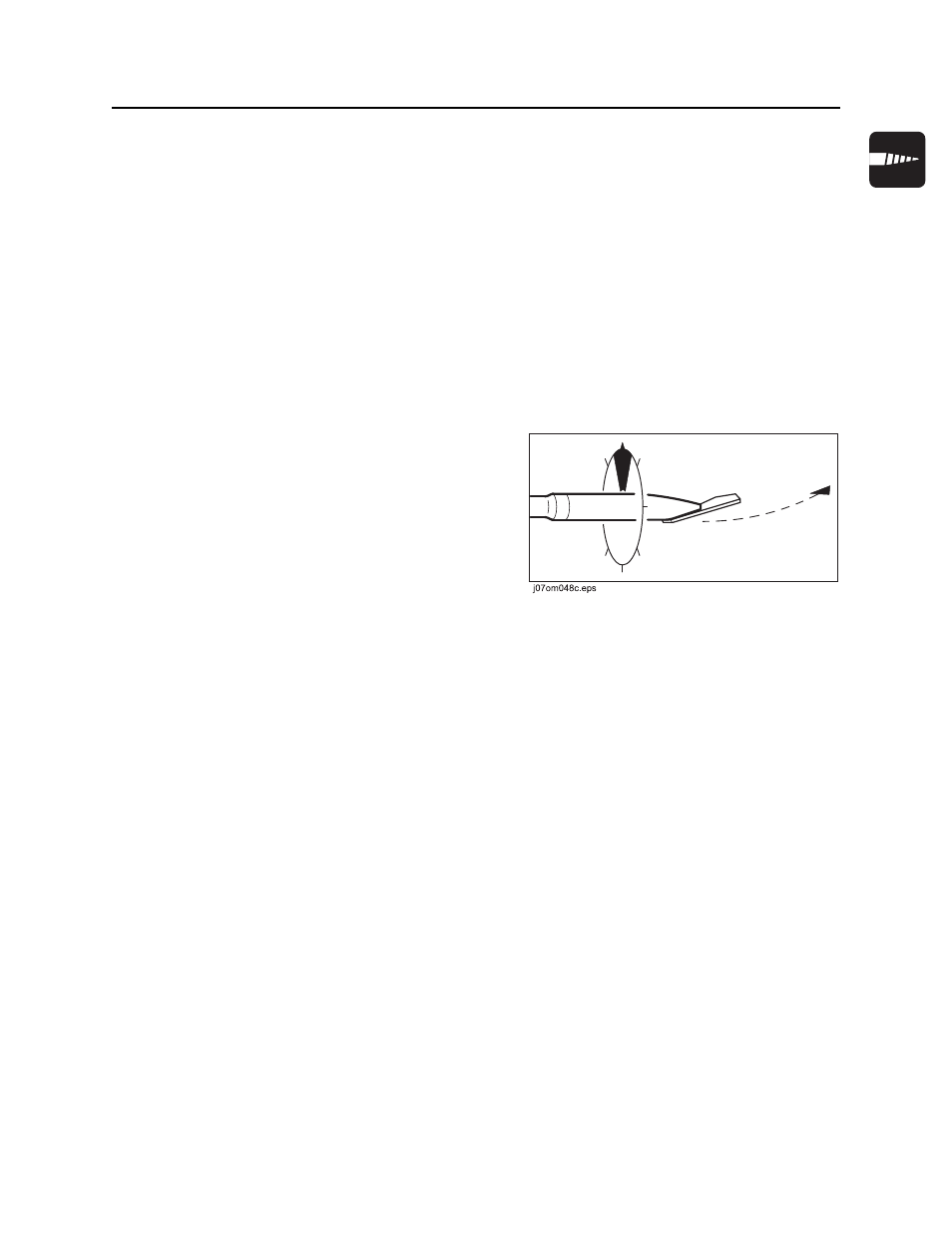

Drill Head Position

The drill head position is determined by reading

beacon roll. Roll is displayed as a clock face position.

1.

Read beacon roll.

2.

Slowly rotate pipe until tracker displays desired

beacon roll.

To change direction:

1.

Rotate pipe to clock position you intend to travel.

2.

Push pipe into ground.

To move forward without changing direction:

1.

Rotate pipe.

2.

Push pipe into ground.

See also other documents in the category Ditch Witch Special machinery:

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- P80 (71 pages)

- OnGrade (63 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT80 (203 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)