Clamp pipe, Jt25 operator’s manual – Ditch Witch JT25 User Manual

Page 91

Conduct a Bore - 90

JT25 Operator’s Manual

Clamp Pipe

CMW

Clamp Pipe

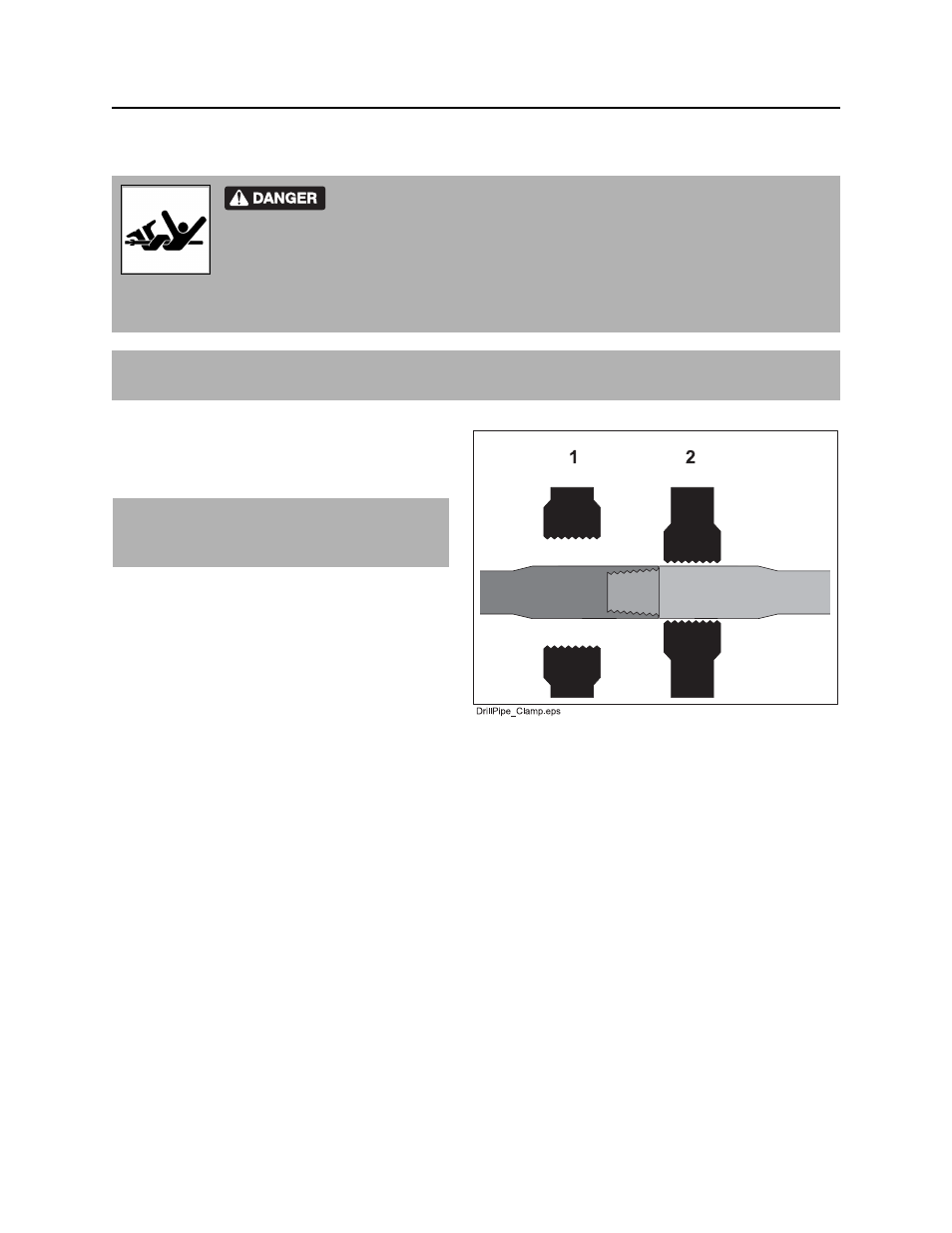

Clamp on pipe when joint is between wrenches

(1 and 2). Always clamp on the larger diameter

areas on either side of the tool joint face.

Turning shaft can kill you or crush arm or leg. Stay away.

To help avoid injury: Only clamp pipe at reinforced end. Clamping anywhere else on the pipe will

weaken the pipe. Pipe can later break, even when operating under normal loads.

NOTICE: Wrenches can open after engine shutdown. Ensure that any downhole tool or pipe in tool joint

vises is attached to spindle or removed before transport.

NOTICE: Clamping pipes on top of female

end threads can damage threads. Only clamp

female pipe ends behind the threads.

See also other documents in the category Ditch Witch Special machinery:

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- P80 (71 pages)

- OnGrade (63 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT80 (203 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)