Use drill pipe correctly, Jt25 operator’s manual – Ditch Witch JT25 User Manual

Page 133

Systems and Equipment - 132

JT25 Operator’s Manual

Drill Pipe

CMW

Use Drill Pipe Correctly

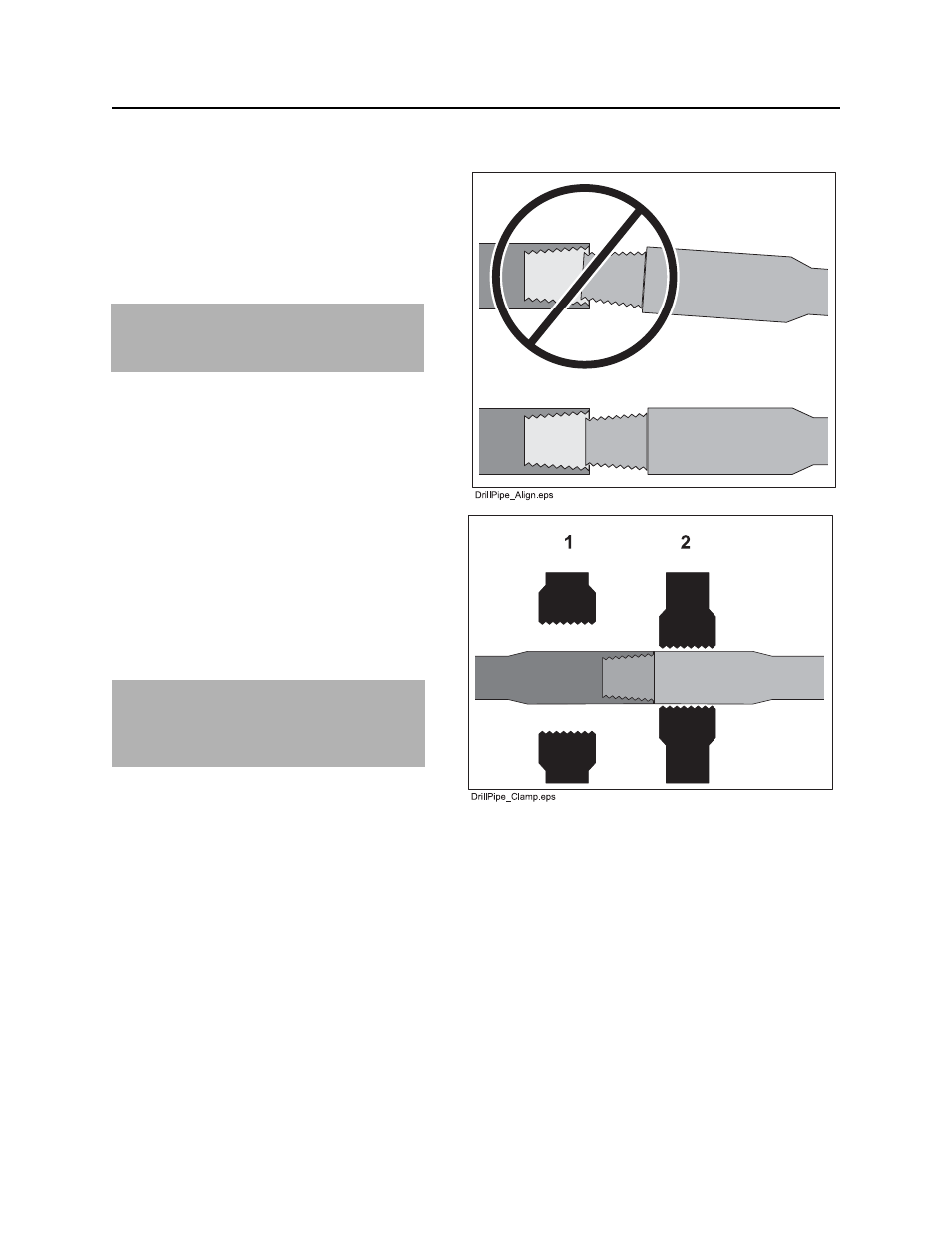

Align the Joints

Always carefully align the male and female

ends of pipe before threading them together.

Poor alignment can damage the threads and

destroy the usefulness of the joint.

Clamp Pipe Correctly

Clamp on pipe when joint is between

wrenches. Clamp only on the tool joint of the

drill pipe as shown. This portion of the drill

pipe is designed for clamping and is

considerably thicker and stronger than the

rest of the pipe.

See “Clamp Pipe” on page 90 for more

information.

NOTICE: If joints get out of alignment

during a bore, use frame tilt or rear

stabilizers to adjust the unit.

NOTICE: Clamping anywhere else on the

pipe will weaken the pipe. Pipe can later

break, even when operating under normal

loads.

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- P80 (71 pages)

- OnGrade (63 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT80 (203 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)