Delta RMC101 User Manual

Page 53

RMC100 Startup

Appendix B: Tuning

53

deltamotion.com

commands numerous times. Doing this from a PLC or by typing commands in

RMCWin is very awkward. To simplify the process, Event Steps in RMCWin

should be used for setting up and tuning position/pressure control.

To perform position/pressure control, the following steps must be set up in the

Event Step Table:

1. Issue a P command so the axis will hold position.

2. Issue a Set Null Drive to Integral Drive (n) command. This updates the

null drive (drive needed to hold position), which is critical for pressure

control.

3. Move the axis to the correct starting position. Normally, the axis should be

at a position where the pressure is below the desired entry pressure

(Pressure Set A).

4. Set up the pressure control mode. This sets up the parameters that the

pressure axis will use when it enters pressure regulating mode. This is done

by issuing the Set Pressure (^) command.

Note: this step does not put the axis into pressure regulating mode.

This step sets up the following parameters:

Mode

Sets Ramp Type, Ramp Time and Integrator

Mode

Pressure Set A

Pressure at which Pressure control begins.

Pressure Set B

Pressure at which Pressure control ends.

Ramp Time

Time to ramp to commanded pressure.

Command Pressure

The pressure the system will go to when

regulating pressure.

5. Move in the direction of increasing pressure with the monitor pressure bit

set (pressure monitoring mode). When the pressure reaches Pressure Set A,

the axis enters pressure regulating mode. The axis enters pressure control

according to the parameters previously set up by the Set Pressure

command.

6. Control the pressure as desired.

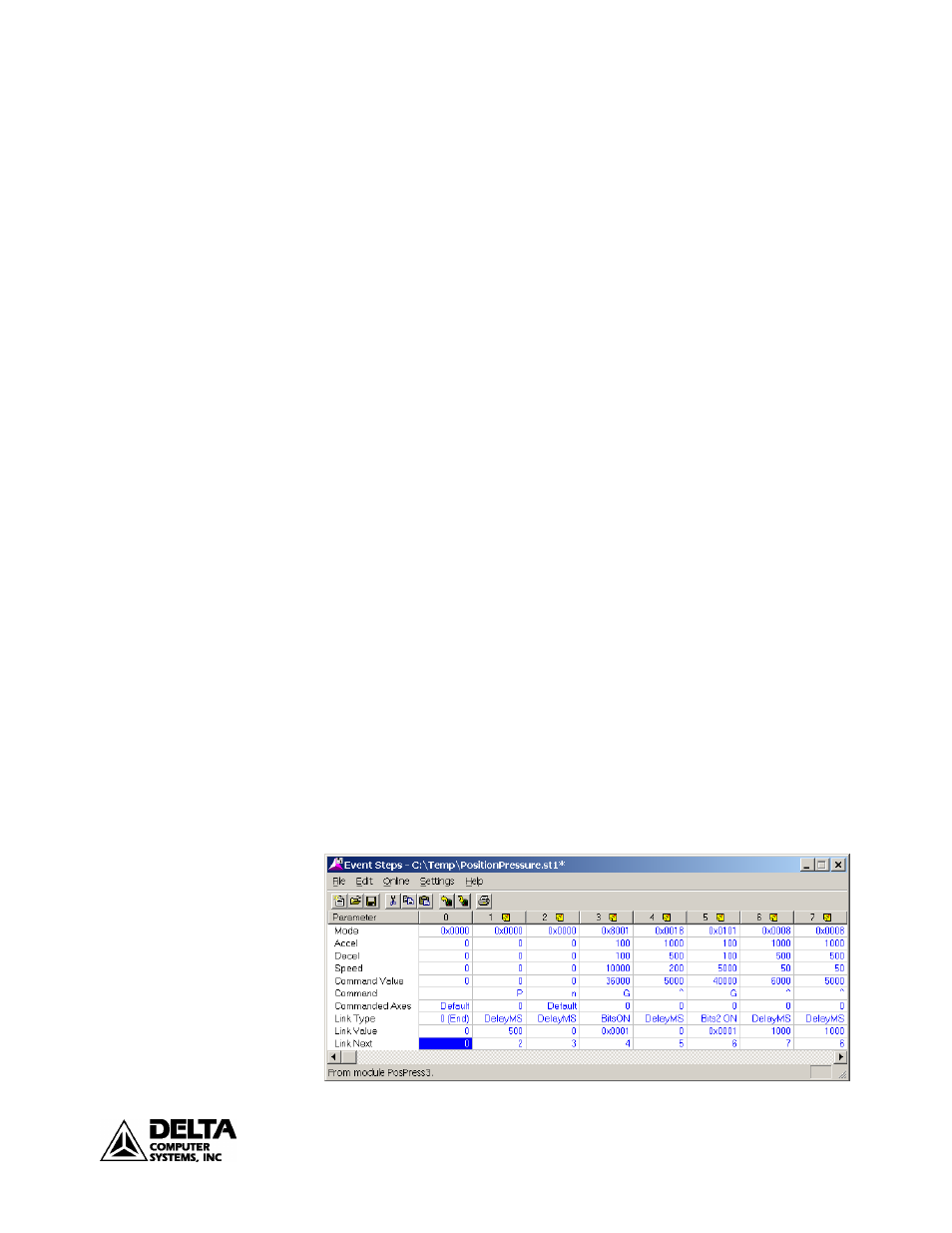

The following sample Event Step Table illustrates these steps:

Explanation of each step in the Event Step table: